High-entropy alloy composite coating layer for surface protection for aluminum die-casting die

A technology of high-entropy alloy and composite coating, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc. Combined force and other issues to achieve the effect of preventing crack propagation, good interface bonding, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

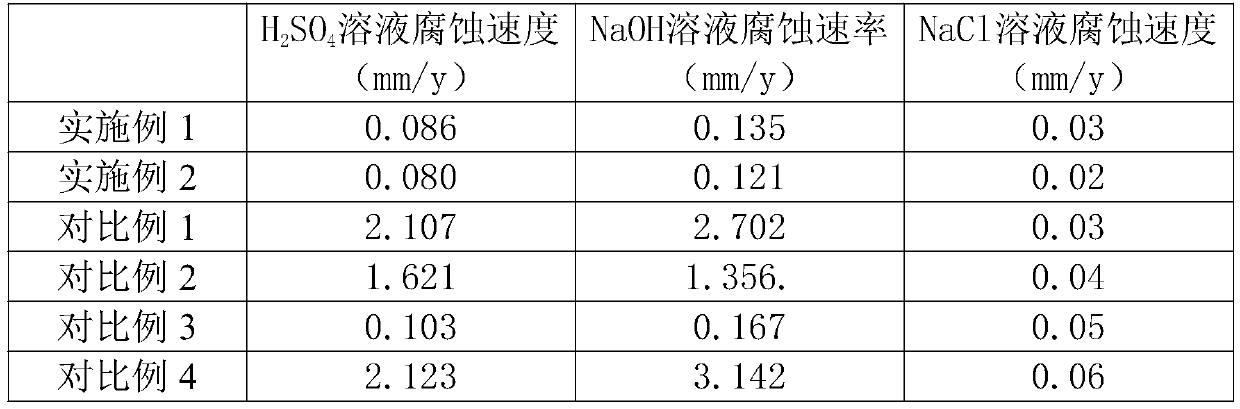

Embodiment 1

[0026] A method for preparing a high-entropy alloy composite coating for surface protection of an aluminum die-casting mold, comprising the following preparation steps:

[0027] Step 1: Select the aluminum alloy die-casting mold as the base material, select corundum sand with a grit size of 320 mesh, and perform sandblasting treatment on the aluminum alloy die-casting mold under the air pressure of 2 Bar to remove the passivation layer on the surface; Grind the aluminum alloy die-casting mold with 300, 400, 600, and 800 sandpaper; then use a polishing cloth wheel to mix diamond grinding powder and grinding diamond powder olive oil for grinding and fine polishing. The diamond powder has a particle size of 0.5 μm; use automatic ultrasonic cleaning , the specific process is to spray and clean the aluminum alloy die-casting mold with lye for 10 minutes, the pressure during leaching is 3kg / cm2, and then place the leached aluminum alloy die-casting mold in lye at 80°C and perform ult...

Embodiment 2

[0035] A method for preparing a high-entropy alloy composite coating for surface protection of an aluminum die-casting mold, comprising the following preparation steps:

[0036] Step 1: Select the aluminum alloy die-casting mold as the base material, select corundum sand with a grit size of 400 mesh, and perform sandblasting treatment on the aluminum alloy die-casting mold under an air pressure of 4 Bar to remove the passivation layer on the surface; 300, 400, 600, 800 sandpaper to polish the aluminum alloy die-casting mold; then use a polishing cloth wheel to mix diamond grinding powder and grinding diamond powder olive oil for grinding and fine polishing. The diamond powder has a particle size of 1 μm; use automatic ultrasonic cleaning, The specific process is to spray and clean the aluminum alloy die-casting mold with lye for 20 minutes, the pressure during rinsing is 3kg / cm2, and then place the leached aluminum alloy die-casting mold in 86°C lye and perform ultrasonic clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com