Laser desorption ionization mass spectrometry method and system

An ionization mass spectrometry and analysis method technology, which is applied in the field of laser desorption ionization mass spectrometry analysis, can solve problems that have not been reported yet, and achieve avoidance of inhomogeneous co-crystallization, sensitive mass spectrometry soft ionization detection and mass spectrometry imaging analysis, and simplified operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

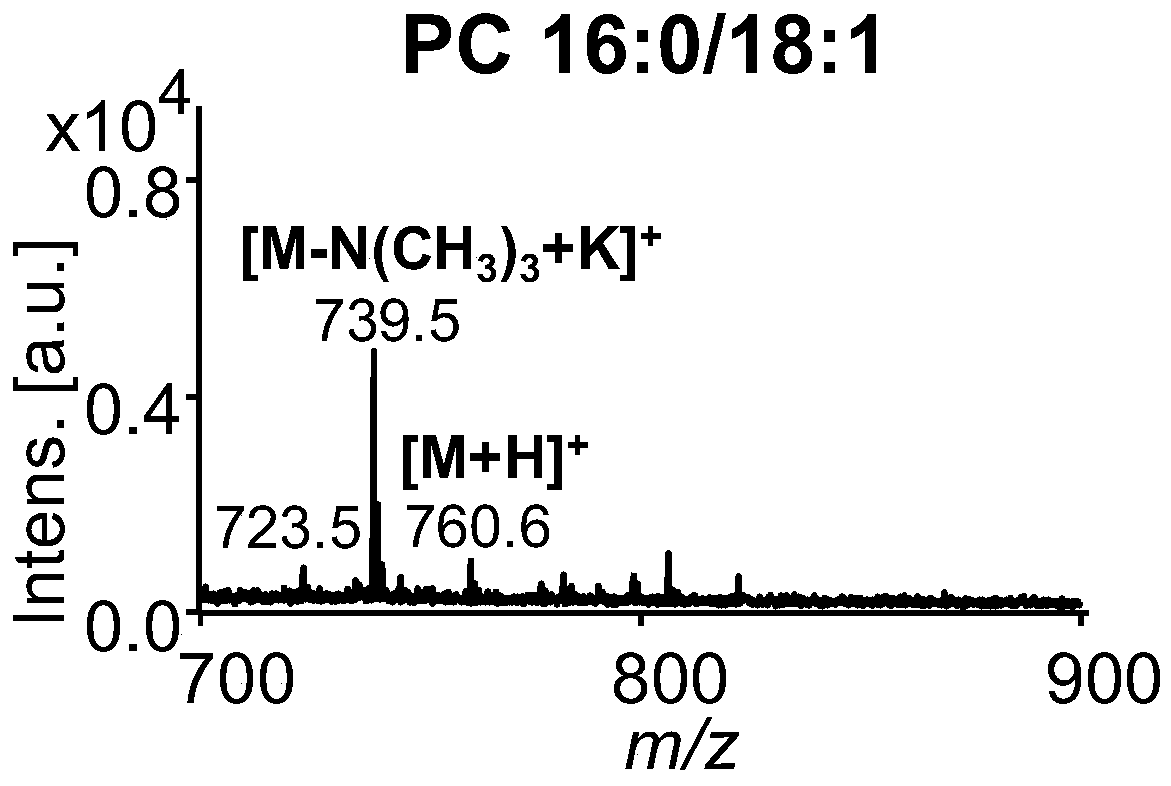

[0036] Example 1 Using polydopamine-modified stainless steel sheets and polydopamine-modified laser-etched stainless steel sheets as sample-loading substrates for laser desorption ionization mass spectrometry analysis of different analytes

[0037] Preparation of analytical samples: Glucose solution with a concentration of 1mg / ml, the solvent is water; phosphatidylcholine PC 16:0 / 18:1 solution with a concentration of 10μM, the solvent is methanol / water 1 / 1; the concentration is 0.2mg / ml of angiotensin II solution, the solvent is methanol / water 3 / 7; configure polyethylene glycol PEG 600 (0.1μL / L), PEG 1000 (15μL / L), PEG 2000 (20μL / L) mixture solution , placed in a 4°C refrigerator for later use.

[0038] Laser etching stainless steel sheet: the manufacturing method is as patent application CN103627883, made on stainless steel (304).

[0039] Polydopamine modification: prepare a dopamine solution with a concentration of 2 mg / ml, the solvent is a 10 mM aqueous solution of trish...

Embodiment 2

[0046] Example 2 Laser desorption ionization mass spectrometry analysis using polydopamine-modified stainless steel sheet as a sample-loading substrate

[0047] Preparation of analytical samples: prepare a glucose solution with a concentration of 1 mg / ml, use water as a solvent, and place it in a refrigerator at 4°C for use.

[0048] Polydopamine-modified stainless steel sheet: prepare a dopamine solution with a concentration of 0.25 mg / ml, and a solvent of 10 mM tris aqueous solution (pH 8-9), place it in an open beaker and stir; wait for the resulting solution to change color Finally, the solid material to be modified was directly put into it to soak and stirred continuously at a speed of 300 rpm, reacted at room temperature for 15 hours, and then taken out. The obtained target plate was thoroughly washed with deionized water to remove surface impurities and dopamine monomers, and then dried in an oven.

[0049] LDI mass spectrometry analysis:

[0050] (1) The polydopamine...

Embodiment 3

[0052] Example 3 Laser desorption ionization mass spectrometry analysis of human plasma and plasma extracts using polydopamine-modified laser-etched stainless steel sheet as a sample-loading substrate

[0053] Preparation of plasma extract: 50 μL of human plasma was added to 1 mL of deionized water, and then 1 mL of methanol and 2 mL of chloroform were added. After vortexing for 5 minutes, place in a centrifuge and centrifuge for 8 minutes (11269×g), collect the chloroform phase, blow dry with nitrogen, then redissolve the precipitate in 1 mL of methanol, and store in a -20°C refrigerator for later use.

[0054] Laser etching stainless steel sheet: the manufacturing method is as patent application CN103627883, made on stainless steel (304).

[0055] Polydopamine modification: prepare a dopamine solution with a concentration of 2 mg / ml, the solvent is a 10 mM aqueous solution of trishydroxymethylaminomethane (pH is 8 to 9), place it in an open beaker and stir; after the resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com