Preparation method of iron-doped cobalt diselenide nanosheet/reduced graphene composite electrode material

A technology of graphene composite and cobalt diselenide, which is applied in battery electrodes, nanotechnology, secondary batteries, etc., can solve the problems of large volume expansion effect, long battery activation cycle, and poor cycle stability, so as to improve conductivity, Effect of reduced electrochemical activation time and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

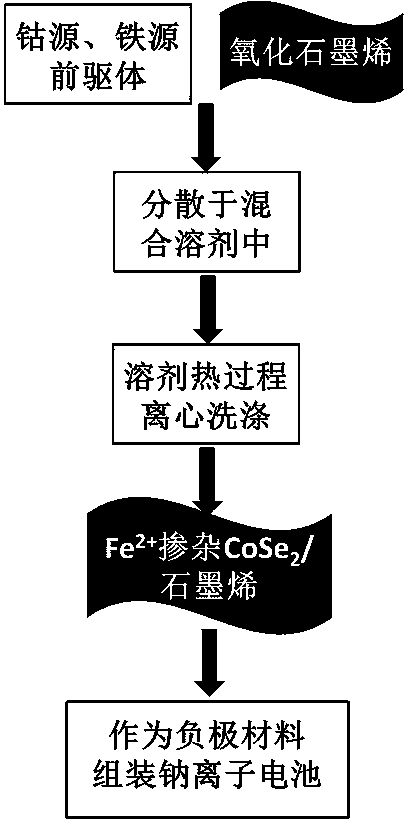

[0029] A preparation method of iron-doped cobalt diselenide nanosheet / reduced graphene composite electrode material, the steps are as follows:

[0030] Weigh 0.291 g of cobalt nitrate hexahydrate and ferric nitrate of different masses (0, 0.007, 0.0103, 0.014, 0.0175 g) and dissolve them in a mixed solvent of 14 mL of water and 26 mL of ethylenediamine, and stir until dissolved; weigh 0.158 g Selenium powder (the mass ratio of mixed dispersion liquid and selenium salt is 155:1) was stirred and dispersed for 2 h at 25 ° C under the control of the stirring speed of 200 r / min. o The reaction was performed at C for 16 h. After the reaction, the product was centrifuged and washed with a mixed solvent of water and ethanol, and then the sample was dried in a blast drying oven for 60 o C was dried overnight to obtain the final product.

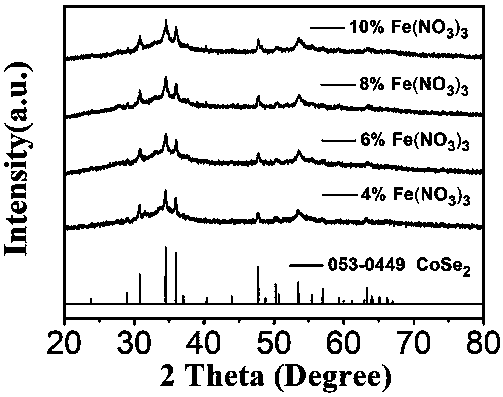

[0031] like figure 2 As shown in the figure, it can be seen from the figure that all the diffraction peaks are consistent with the standard patter...

Embodiment 2

[0035] A preparation method of iron-doped cobalt diselenide nanosheet / reduced graphene composite electrode material, the steps are as follows:

[0036] 0.05 g of graphene oxide was weighed and dissolved in a mixed solvent of 14 mL of water and 26 mL of ethylenediamine, and ultrasonically dispersed for 2 hours, then 0.268 g of cobalt nitrate hexahydrate and 0.032 g of ferric nitrate nonahydrate were added to the above solution, and stirred until Dissolve, the stirring speed is 100 rpm, the dispersion temperature is 50 °C, and the dispersion time is 0.1 h; 0.158 g of selenium powder (the ratio of dispersion liquid and selenium salt is 155:1) is weighed, and the stirring speed is controlled at 25 °C Stir and disperse at 200 r / min for 2 h, put the above solution in a reaction kettle, and react at 180 °C for 16 h. After the reaction, the product is centrifuged and washed with a mixed solvent of water and ethanol, and then the sample is dried in a blast drying oven for 60 Dry at °C ...

Embodiment 3

[0039] A preparation method of iron-doped cobalt diselenide nanosheet / reduced graphene composite electrode material, the steps are as follows:

[0040] 0.05 g of graphene oxide was weighed and dissolved in a mixed solvent of 14 mL of water and 26 mL of diethylenetriamine, and ultrasonically dispersed for 2 hours, then 0.312 g of cobalt acetate tetrahydrate and 0.003 g of ferric acetate were added to the above solution, and stirred. To dissolve, the stirring speed is 200 rpm, the dispersion temperature is 30 °C, and the dispersion time is 3 h; 0.667 g of selenium powder (the ratio of dispersion liquid and selenium salt is 60:1) is weighed, and the stirring speed is controlled at 50 °C. Stir and disperse at 500 r / min for 5 h, place the above solution in a reaction kettle, and react at 200 °C for 24 h. After the reaction, the product is centrifuged and washed with a mixed solvent of water and ethanol, and then the sample is dried in a blast drying oven for 60 Dry at °C overnight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com