Large-scale preparation and purification method and application of mu-conopeptide

A purification method and cono peptide technology, which is applied to the preparation method of peptides, chemical instruments and methods, cosmetic preparations, etc., can solve problems such as high cost, difficult extraction, and failure to meet market demand, so as to improve efficiency and operate Simple, Pain-Free Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1B

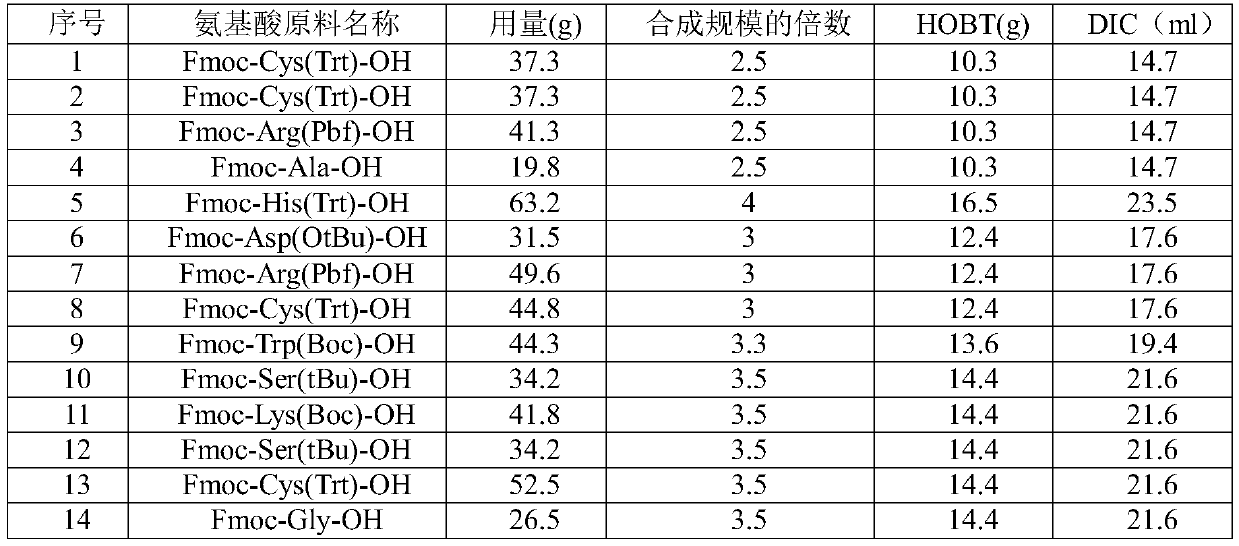

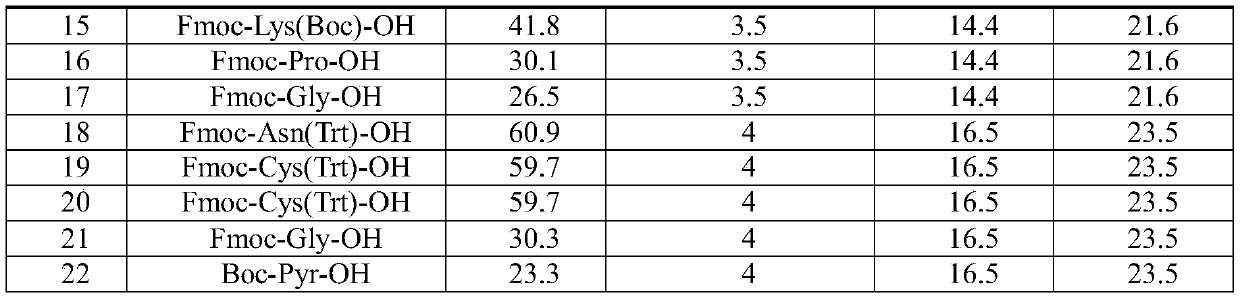

[0052] Example 1 Boc-pGlu-Gly-Cys(Trt)-Cys(Trt)-Asn(Trt)-Gly-Pro-Lys(Boc)-Gly-Cys(Trt)-Ser(tBu)-Lys(Boc)-Ser

[0053] Preparation of (tBu)-Trp(Boc)-Cys(Trt)-Arg(Pbf)-Asp(OtBu)-His(Trt)-Ala-Arg(Pbf)-Cys(Trt)-Cys(Trt)-Amino Resin

[0054] 1.1 Resin swelling

[0055] Add 75g of Rink AM resin with a degree of substitution of 0.7 into the solid-phase column, add 500ml of DMF to completely immerse the resin, then blow in nitrogen, start stirring at 100r / min, stir for 5min, and then drain the solvent for 5min. Then add 500ml of DMF, completely immerse the resin, pass nitrogen gas, start stirring, 100r / min, stir for 30min, and drain the solvent. Continue to add 500ml of DMF, completely immerse the resin, pass nitrogen gas, start stirring, 100r / min, and drain the solvent for 5min to complete the swelling.

[0056] 1.2 De-Fmoc

[0057] Add 500ml of 20% piperidine / DMF, blow in nitrogen gas, stir the reaction for 5min, and drain it for 3min. Then add 500ml of 20% piperidine / DMF, blow ...

Embodiment 2

[0070] Example 2H-pGlu-Gly-Cys-Cys-Asn-Gly-Pro-Lys-Gly-Cys-Ser-Lys-Ser-Trp-Cys-Arg-Asp-His-Ala-Arg-Cys-

[0071] Cys-NH 2 preparation of

[0072] 2.1 Reagent pretreatment

[0073] Put TFA, isopropyl ether, and ether into the refrigerator for more than 4 hours. Phenol in 60°C water bath for 2h.

[0074] 2.2 Cracking operation

[0075] Weigh 90g of the resin to be cracked and put it into a 1L round bottom flask.

[0076] Measure 15.7ml of ethanedithiol, 31.5ml of sulfide anisole, 15.7ml of water, 535.5ml of TFA, and 31.5ml of phenol, mix them evenly, and pour them into a 1L round bottom flask filled with resin, magnetic stirring, 500r / min, the reaction time is 2.5h.

[0077] After 2.5 hours of cleavage reaction, the lysate was concentrated below 38°C for 1 hour, and the lysate resin was vacuum filtered with a sand core filter funnel, and dried for 1 minute. Add 15ml TFA to wash the resin, and drain it for 1min. Add 15ml TFA again to wash the resin, and drain it for 1min...

Embodiment 3

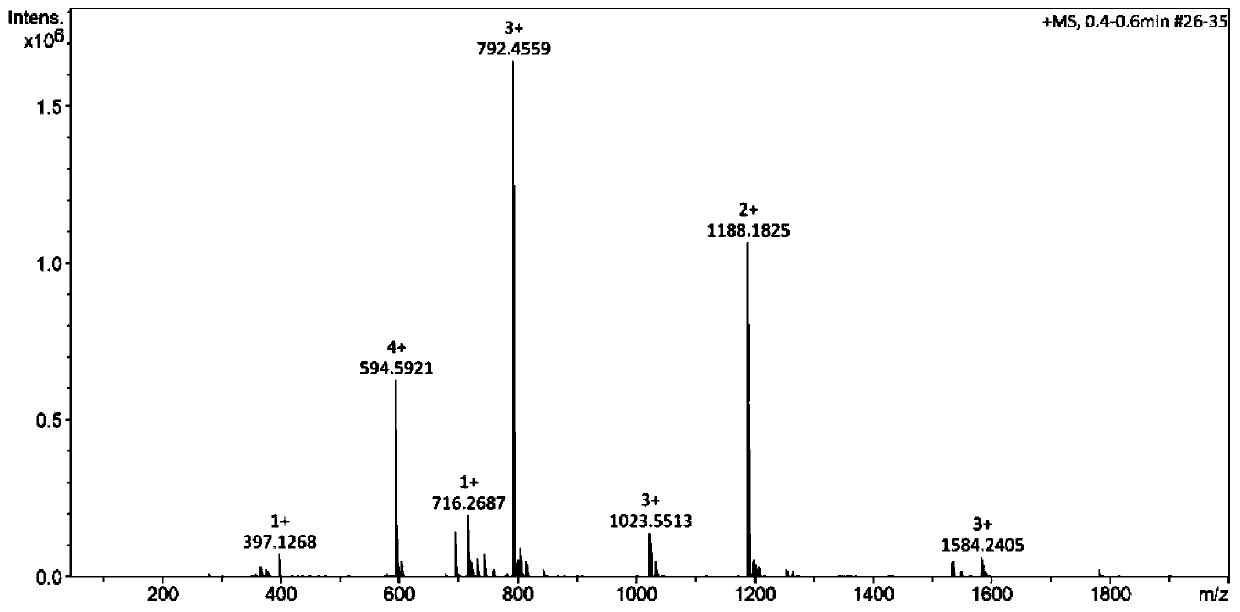

[0084]

[0085] 3.1 Preparation of 0.1mol / L buffer solution

[0086] Weigh 102g of Tris into a 10L serum bottle, add 8.5L of purified water, stir, and adjust the pH to 8.2 to obtain a 0.1mol / L Tris buffer.

[0087] 3.2 Oxidative folding operation

[0088] After the crude peptide was taken out from the vacuum desiccator and weighed (about 30 g), it was immediately put into a buffer solution in a 10 L serum bottle, and stirred for 16 hours. The color of the solution is clear and bright yellow. The buffer solution of the crude product of μ-conopeptide formed by oxidative folding to form three pairs of disulfide bonds was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com