Preparation method of wheat germ polypeptide fast-food powder

A technology of wheat germ and instant flour, which is applied in the directions of food forming, function of food ingredients, food science, etc., can solve the problems of single flavor and insufficient release of nutrients, so as to increase flavor substances, enrich taste, improve The effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

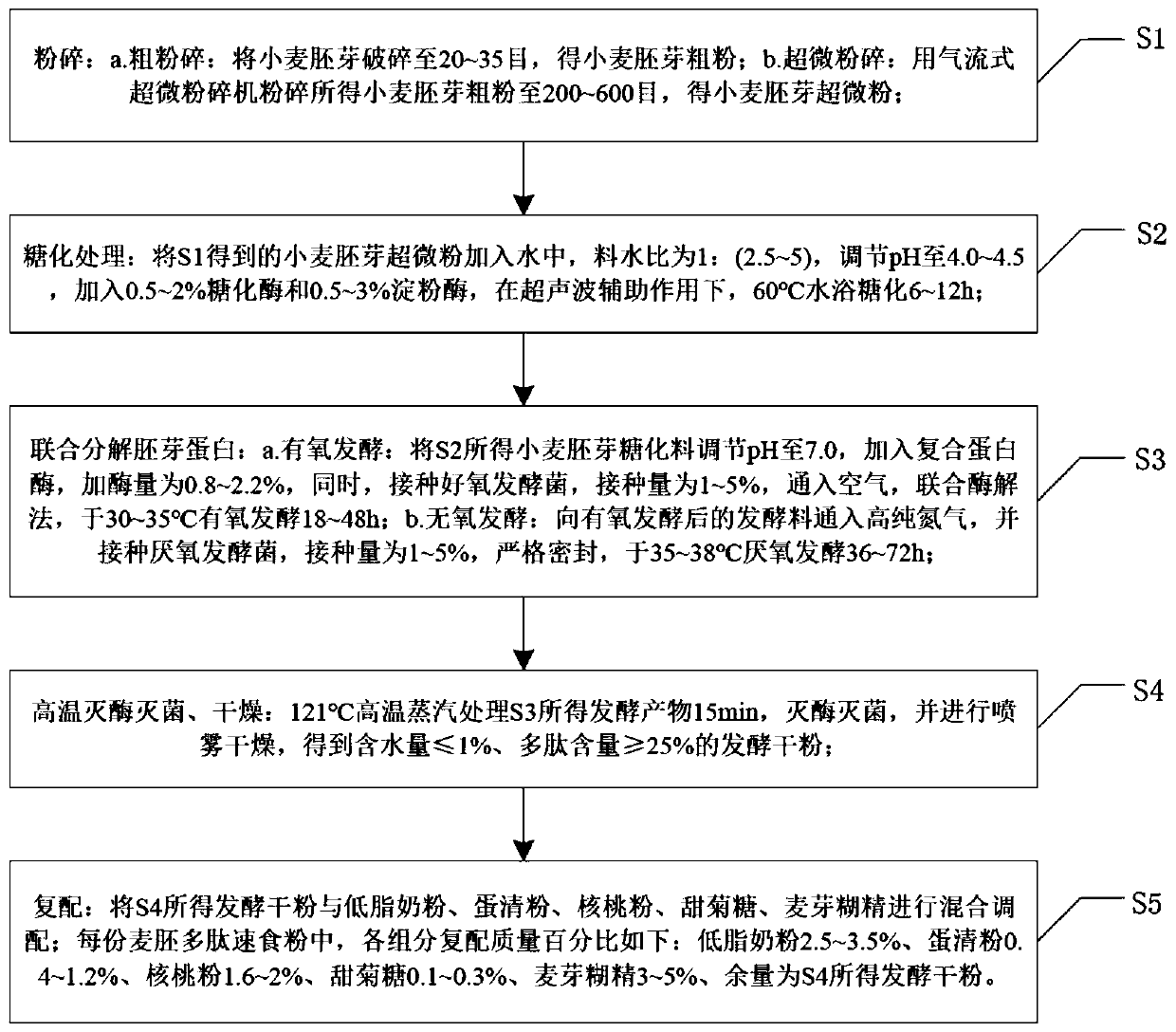

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares wheat germ polypeptide instant powder

[0027] S1: Smash:

[0028] a. Coarse crushing: crushing wheat germ to 30 meshes to obtain wheat germ coarse powder;

[0029] b. Superfine pulverization: pulverize the obtained wheat germ coarse powder to 500 mesh with an airflow type superfine pulverizer to obtain wheat germ superfine powder;

[0030] S2: Saccharification treatment: add the superfine wheat germ powder obtained in S1 into water, the ratio of material to water is 1:3, adjust the pH to 4.5, add 1% glucoamylase and 1.5% amylase, and under the assistance of ultrasonic waves with a frequency of 30KHz, 60 ℃ water bath saccharification for 12h;

[0031] S3: Combined decomposition of germ protein:

[0032] a. Aerobic fermentation: adjust the pH of the wheat germ saccharification material obtained in S2 to 7.0, add complex protease, the amount of enzyme added is 0.8%, at the same time, inoculate aerobic fermentation bacteria, the inoculum amount is ...

Embodiment 2

[0036] Embodiment 2 prepares wheat germ polypeptide instant powder

[0037] S1, S2 are the same as embodiment 1;

[0038] S3: Combined decomposition of germ protein:

[0039] a. Aerobic fermentation: adjust the pH of the wheat germ saccharification material obtained in S2 to 7.0, add complex protease, the enzyme amount is 1.5%, at the same time, inoculate aerobic fermentation bacteria, the inoculum amount is 3%, pass in air, and combine enzymatic hydrolysis , fermented aerobically at 35°C for 32h; the complex protease was mixed with neutral protease, papain, bromelain, and carboxypeptidase A at a mass ratio of 1:1.2:0.7:0.2; the aerobic fermentation bacteria were composed of Saccharomyces cerevisiae, Bacillus subtilis, and Bacillus licheniformis are mixed at a mass ratio of 1:1.2:1;

[0040] b. Anaerobic fermentation: feed high-purity nitrogen into the fermented material after aerobic fermentation, and inoculate anaerobic fermentation bacteria, the inoculation amount is 3%, ...

Embodiment 3

[0043] Embodiment 3 prepares wheat germ polypeptide instant powder

[0044] S1, S2 are the same as embodiment 1;

[0045] S3: Combined decomposition of germ protein:

[0046] a. Aerobic fermentation: adjust the pH of the wheat germ saccharification material obtained in S2 to 7.0, add complex protease, the enzyme amount is 2.2%, at the same time, inoculate aerobic fermentation bacteria, the inoculum amount is 5%, pass air, and combine enzymatic hydrolysis , fermented aerobically at 35°C for 48 hours; the composite protease was mixed with neutral protease, papain, bromelain, and carboxypeptidase A at a mass ratio of 1:1.3:0.8:0.2; the aerobic fermentation bacteria were composed of Saccharomyces cerevisiae, Bacillus subtilis and Bacillus licheniformis are mixed according to the mass ratio of 1:1.5:1.2;

[0047] b. Anaerobic fermentation: feed high-purity nitrogen into the fermented material after aerobic fermentation, and inoculate anaerobic fermentation bacteria with an inoculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com