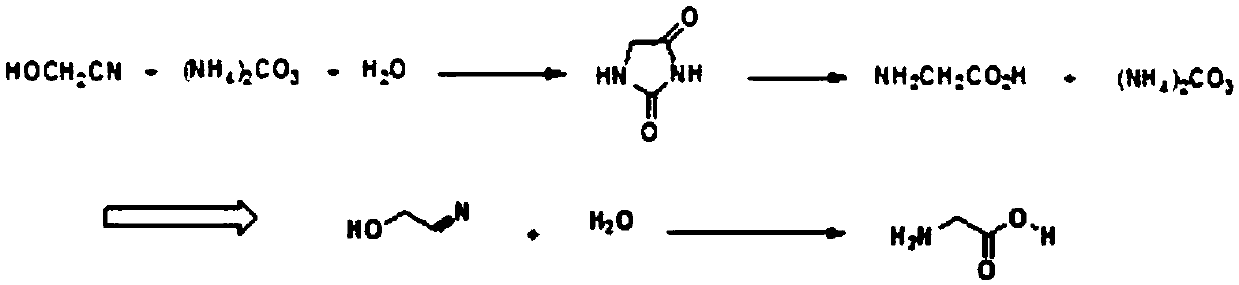

Method for efficiently producing glycine and identification of glycine produced by hydantoin method

A production method and technology of glycine products, applied in chemical instruments and methods, preparation of organic compounds, material separation, etc., can solve the problems of difficult product refinement, decomposition of raw materials, high production cost, etc., and achieve the effect of enriching quality inspection content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

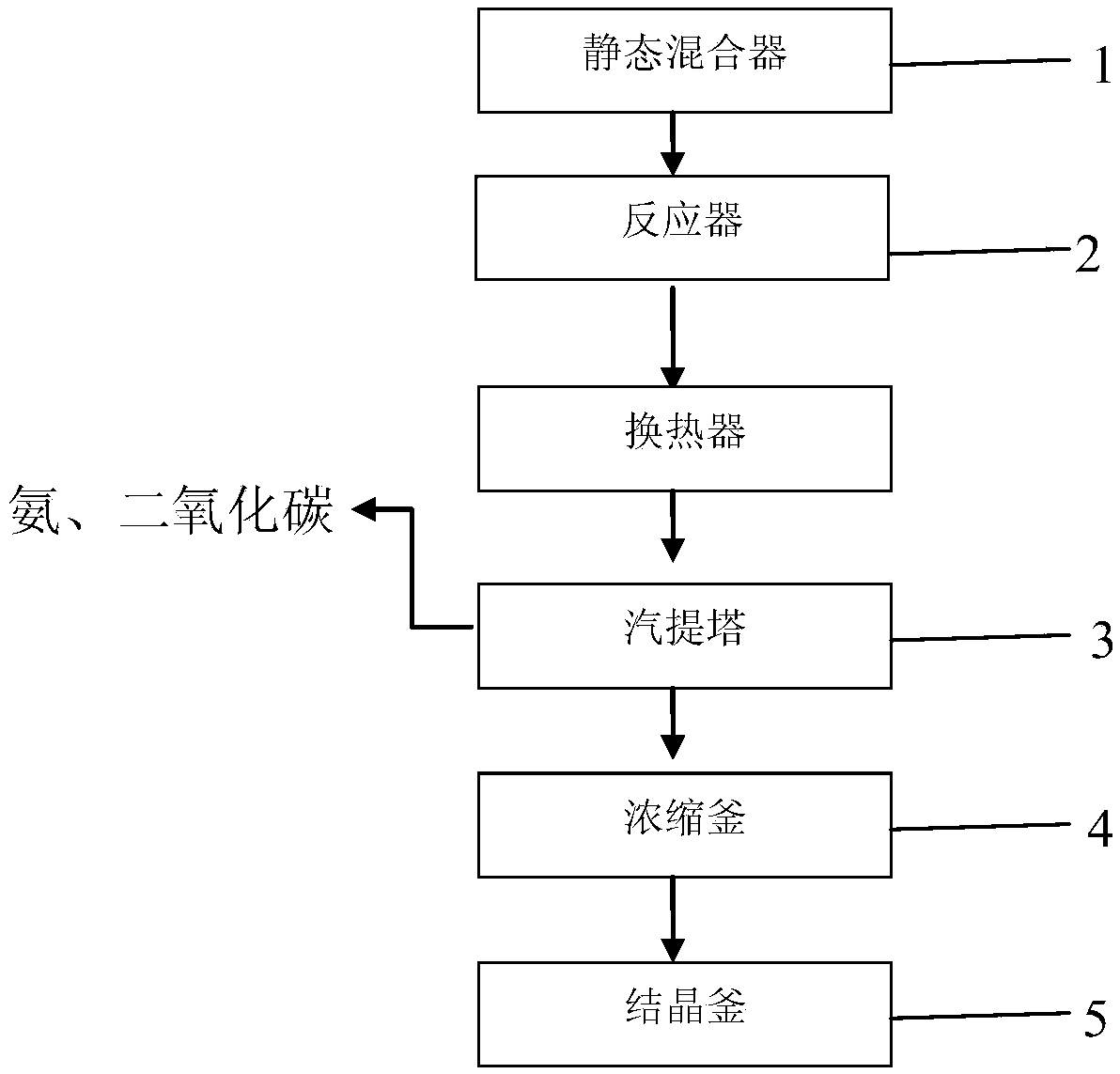

Method used

Image

Examples

Embodiment 1

[0087] Add 193.94 g (2.0 mol) of ammonium carbonate with a purity of 99.0%, 483 g of pure water, and 95 g of 40% hydroxyacetonitrile into a 1000 ml pressure-resistant reactor equipped with a pressurized sampling device and a stirring device, and mix well. The temperature was maintained at 160°C for 2 hours, and the pressure in the reactor was 7.0 MPa.

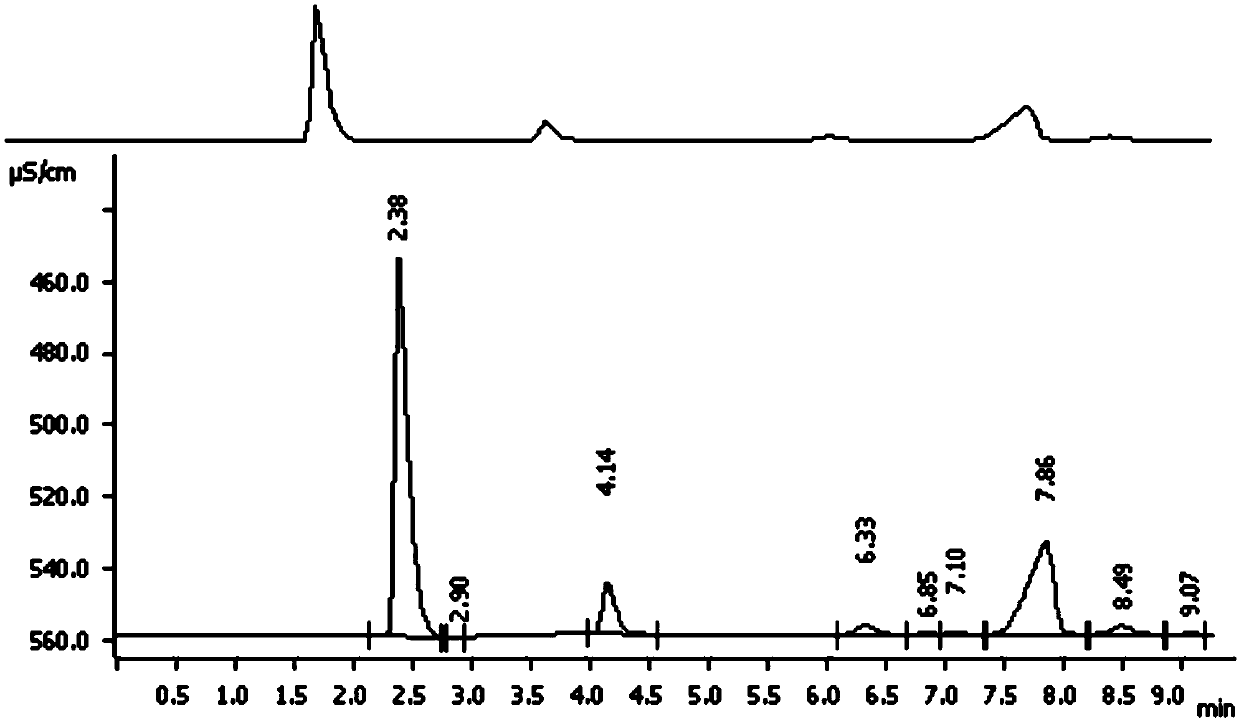

[0088] After the reaction was finished, the pressure was released to normal pressure, and cooled to normal temperature to obtain the hydrolyzed solution, and analyzed by ion chromatography, the yield of glycine was 95%.

[0089] The hydrolyzed solution obtained above is stripped, then concentrated to a glycine content of about 30%, cooled and crystallized, centrifuged to obtain crude glycine, and the crystallization mother liquor is recycled to step 1). The crude glycine product is decolorized by activated carbon and recrystallized, and the crystals are filtered and dried by suction, and the main content of the obtained glycine...

Embodiment 2

[0092] Add 193.94 grams (2.0 mol) of ammonium carbonate with a purity of 99.0% in a 1000 ml pressure-resistant reactor with a pressurized sampling device and a stirring device, 483 g of pure water, add 95 grams of 40% hydroxyacetonitrile, and keep warm at 170 ° C for 2 hours , the pressure in the reactor is 7.0MPa.

[0093] After the reaction finished, the pressure was released to normal pressure, and cooled to normal temperature to obtain the hydrolyzed solution, and analyzed by ion chromatography, the yield of glycine was 96%.

[0094] The hydrolyzed solution obtained above is stripped, then concentrated to a glycine content of about 30%, cooled and crystallized, centrifuged to obtain crude glycine, and the crystallization mother liquor is recycled to step 1). The crude glycine product is decolorized by activated carbon and recrystallized, and the crystals are filtered and dried by suction, and the main content of the obtained glycine product is greater than 98.5%.

[0095]...

Embodiment 3

[0097] Add 483 grams of pure water, 102 grams of ammonia, 88 grams of carbon dioxide, and 95 grams of 40% hydroxyacetonitrile in a 1000ml pressure-resistant reactor with a pressurized sampling device and a stirring device, and mix them uniformly at 165°C for 2 hours. The pressure is 6.2MPa.

[0098] After the reaction was finished, the pressure was released to normal pressure, and cooled to normal temperature to obtain the hydrolyzed solution, and analyzed by ion chromatography, the yield of glycine was 95%.

[0099] The hydrolyzed solution obtained above is stripped, then concentrated to a glycine content of about 30%, cooled and crystallized, centrifuged to obtain crude glycine, and the crystallization mother liquor is recycled to step 1). The crude glycine product is decolorized by activated carbon and recrystallized, and the crystals are filtered and dried by suction, and the main content of the obtained glycine product is greater than 98.5%.

[0100] The detected content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com