The synthetic method of n-vinylpyrrolidone

A technology of vinylpyrrolidone and pyrrolidone, which is applied in the field of synthesis of N-vinylpyrrolidone, can solve the problems of operation controllability, poor product uniformity, and long reaction time, and achieve rapid delivery, precise control, and high product consistency , hot spot or overtemperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

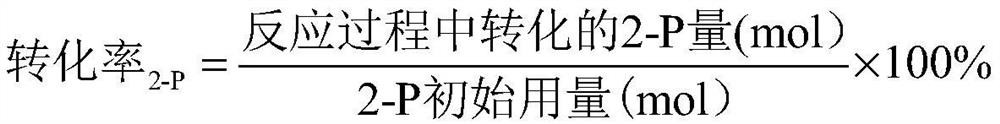

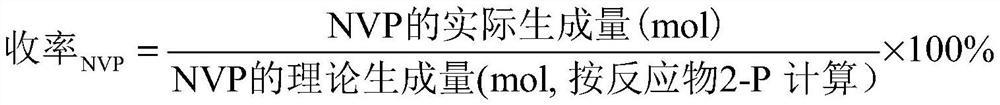

[0036] According to one aspect of the present invention, there is provided a method for synthesizing N-vinylpyrrolidone, comprising: passing acetylene and catalyst-containing 2-pyrrolidone liquid into a microchannel reactor for reaction to obtain N-vinylpyrrolidone;

[0037] Wherein: the content of catalyst in the 2-pyrrolidone liquid containing catalyst is 2.2-10.5wt%; The volume flow ratio of acetylene and the 2-pyrrolidone liquid containing catalyst is (32-270): 1; The inner diameter is less than 3mm.

[0038] In the above synthesis method, a microchannel reactor with a specific single-channel inner diameter is used for the reaction between the reaction raw materials. The inner diameter is very small and has a flame arrester effect, which can greatly reduce the risk of decomposition and explosion of acetylene, and the microchannel reactor also has With high specific surface area and short material diffusion distance, the mass and heat in it can be quickly transferred and pr...

Embodiment 1

[0073] A kind of synthetic method of N-vinylpyrrolidone, comprising:

[0074] Put 0.6kg of potassium hydroxide and 20kg of 2-pyrrolidone in the reaction device for vacuum distillation, keep the pressure at 20mbar, the temperature at 120°C, and finish the reaction after 2h. At this time, the water content in the catalyst-containing 2-pyrrolidone liquid is lower than 500ppm ;

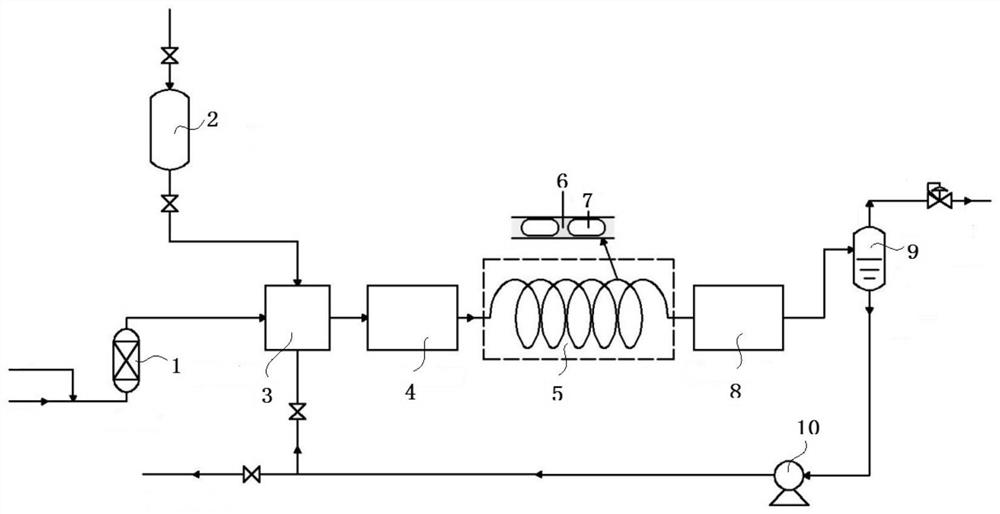

[0075] use figure 1 The process shown in the synthesis of NVP, the total gas flow is 1.8Nm 3 / h, wherein the flow ratio of acetylene and nitrogen is 1:1, nitrogen and acetylene are first dried through drying column 1, the flow rate of the above-mentioned 2-pyrrolidone liquid containing catalyst is 6L / h, and the 2-pyrrolidone liquid containing catalyst is stored in the buffer In the tank 2, the gas and liquid enter the micro-mixer 3 at the set flow rate to achieve mixing at room temperature, then enter the fast heater 4, preheat to 120-135°C, and then enter the tank with a constant temperature of 160°C a...

Embodiment 2

[0078]A kind of synthetic method of N-vinylpyrrolidone, wherein catalyst preparation and technological process are identical with embodiment 1. The reaction temperature is 180°C, and the total gas flow rate is 1.2Nm 3 / h, the above-mentioned catalyzer-containing 2-pyrrolidone liquid flow rate is 12L / h, the inner diameter of a single channel of the microchannel reactor is changed to 0.5mm, and the 316L stainless steel capillary of tube length 40m, other reaction conditions remain unchanged.

[0079] The single-pass conversion rate of 2-pyrrolidone under this operating condition is 7.5%, the total conversion rate of 2-pyrrolidone after 8 cycles is 57.3%, the total reaction time of 8 cycles is 8min, the NVP yield is 57%, and the product NVP The selectivity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com