A kind of ultraviolet curing adhesive and its preparation method and application

A technology of curing glue and ultraviolet light, used in adhesives, non-polymer organic compound adhesives, polyether adhesives, etc., can solve problems such as environmental pollution and high odor, and achieve good bonding performance and low odor toxicity. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A UV-curable adhesive made from the following steps:

[0029] (1) Weigh 2.28g of pentaerythritol tetrakis(3-mercaptopropionate) (monomer A) and 12.76g of trimethylolpropane triacrylate (monomer B) and stir for 100 s; then add 1.52g of epoxy resin 313 (Oligomer C) Mix and stir for 5 minutes until the solution is evenly mixed;

[0030] (2) Add 0.096 g of photoinitiator TPO, 3.14 g of diluent butyl acrylate, 0.05 g of defoamer JY-821 and 0.09 g of antioxidant 1726 into the above mixture in sequence, and stir with a magnetic stirrer under light-shielding conditions 15 min to obtain the UV-curable adhesive.

[0031] The resulting UV-curable adhesive is subjected to a performance test, comprising the following steps:

[0032] (1) Coat the UV-curable adhesive uniformly between the transparent or translucent PET or PVC or PC sheet and various metal sheets by coating or spraying, and compact it to form a thickness of 100 μm adhesive coating;

[0033] (2) The prepared adhesiv...

Embodiment 2

[0035] A UV-curable adhesive made from the following steps:

[0036] (1) Weigh 1.45g of trimethylolpropane (monomer A) and 14.76g of trimethylolpropane triacrylate (monomer B) and stir for 100s; then add 1.78g of epoxy resin 34715 (oligomer C) Mix and stir for 5 minutes until the solution is evenly mixed;

[0037] (2) Add 0.081 g of photoinitiator 819, 3.14 g of diluent isooctyl acrylate, 0.04 g of defoamer JY-821 and 0.10 g of antioxidant 1726 into the above mixture in sequence, and use a magnetic stirrer under shading conditions Stir for 15 min to obtain a UV-curable adhesive.

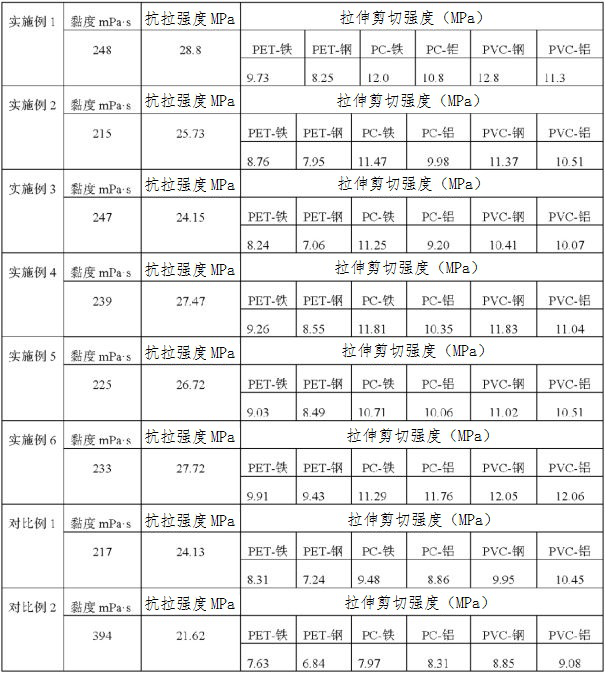

[0038] The performance test of the obtained UV-curable adhesive was the same as in Example 1, and the performance results are shown in Table 1.

Embodiment 3

[0040] A UV-curable adhesive made from the following steps:

[0041] (1) Weigh 2.24g of trimethylolpropane tris(3-mercaptopropionate) (monomer A) and 12.13g of polyethylene glycol 600 diacrylate (monomer B) and stir for 100s; then add 1.44g of ring Oxygen resin 313 (oligomer C) was mixed and stirred for 5 minutes until the solution was evenly mixed;

[0042] (2) Add 0.072 g of photoinitiator 184, 2.73 g of diluent tetrahydrofuryl acrylate, 0.04 g of defoamer JY-821 and 0.09 g of antioxidant 1010 to the above mixture, and stir with a magnetic stirrer under light-shielding conditions 15 min to obtain the UV-curable adhesive.

[0043] The performance test of the obtained UV-curable adhesive was the same as in Example 1, and the performance results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com