Deep hole superlattice filling method based on electrochemical deposition

A filling method, electrochemical technology, applied in the direction of electrical components, nanotechnology, etc., can solve problems such as filling method blockage, and achieve the effects of avoiding reaction interruption, simple and easy operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

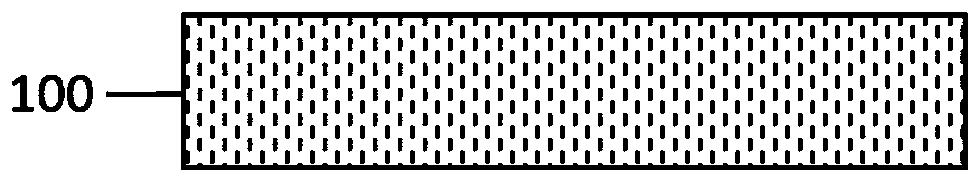

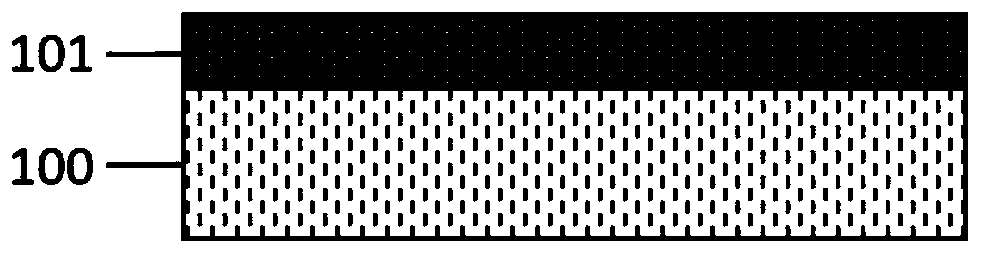

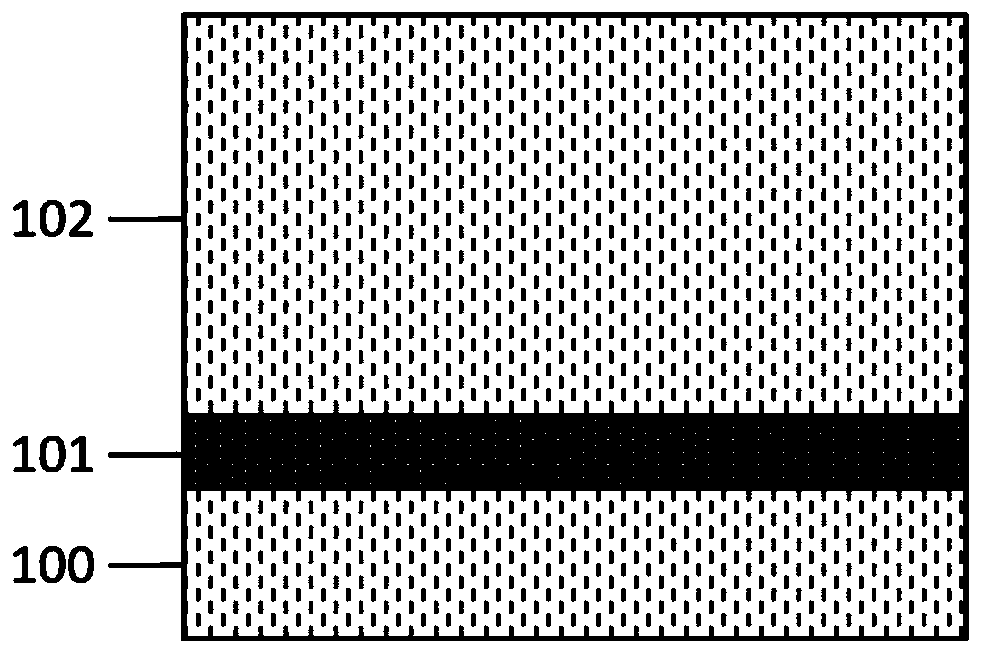

[0067] Place the silicon wafer in acetone and alcohol for ultrasonic cleaning for about ten minutes; after the ultrasonic is completed, use a nitrogen gun to blow off the residual liquid on the surface and dry it for use.

[0068] Use magnetron sputtering or electron beam evaporation to evaporate a metal conductive layer such as titanium platinum, nickel gold, etc. on a clean silicon wafer, with a thickness between 10nm and 200nm. Use PECVD or ALD to grow a layer of dense silicon dioxide or alumina. This step involves a high reaction temperature, but there is no functional layer on the sample, which will not affect the performance of the device. The thickness can reach the micron level or more according to the design requirements.

[0069] Combined with photolithography or other mask processes, the pattern is transferred to the sample. Use the etching method to etch small holes. If the depth of subsequent etching is deeper, the mask can be replaced with a mask that is more re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com