A kind of synthetic method of polyether for low modulus sealant

A synthesis method and sealant technology, applied in the directions of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of reducing the elastic modulus and modifying the high modulus of the sealant, so as to reduce the elastic modulus and improve the quality of the sealant. Tensile properties, the effect of increasing tensile elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for synthesizing polyether for low-modulus sealants, comprising the following steps: adding a mixture of monoalcohol polyoxypropylene ether and polyol polyoxypropylene ether and a metal complex catalyst into a reactor, vacuuming, and using N 2 Replace the air in the reaction kettle, when the vacuum degree is ≥ -0.096Mpa, heat up and dehydrate while pumping vacuum, keep warm and dehydrate for 0.5-2h when the temperature rises to 120-130°C; add propylene oxide to react, the reaction temperature is 100-180°C , The pressure in the reactor is -0.05~0.40Mpa, keep warm and continue the reaction until the pressure no longer drops; after the reaction is completed, vacuum degassing, when the vacuum degree is ≥-0.098Mpa, keep it for 10-30min, and after cooling down, the molecular weight is 4000~ 30,000 polyether for the low modulus sealant.

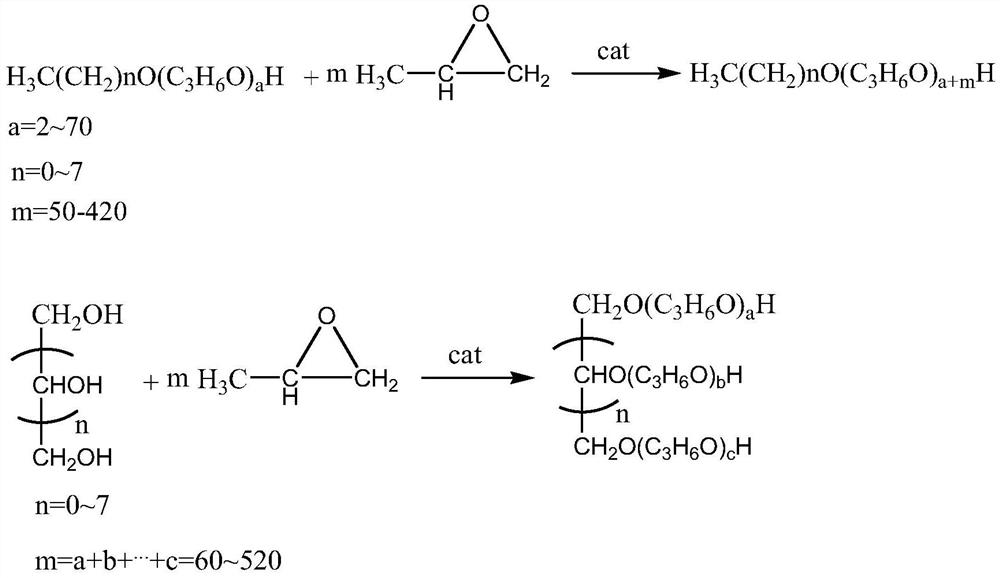

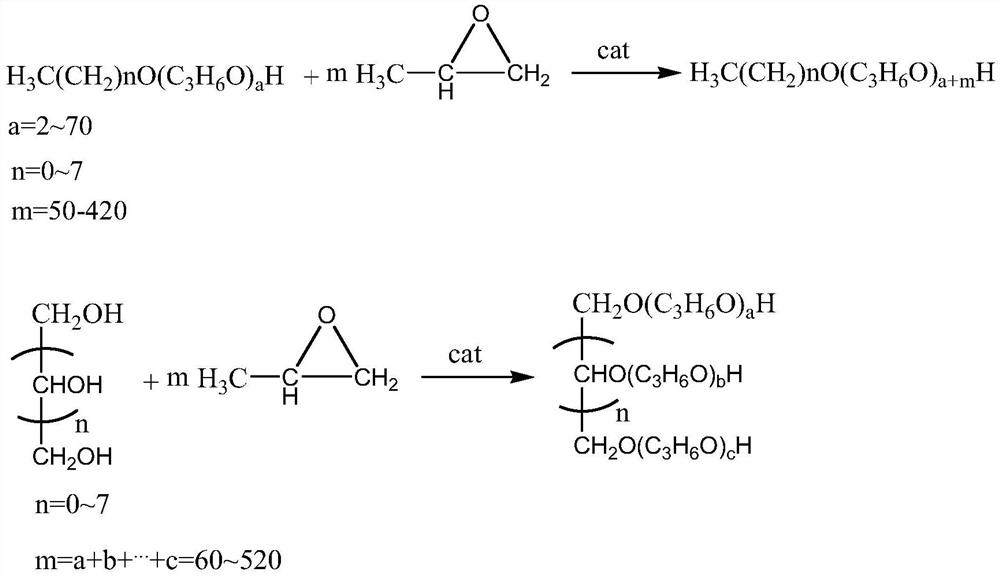

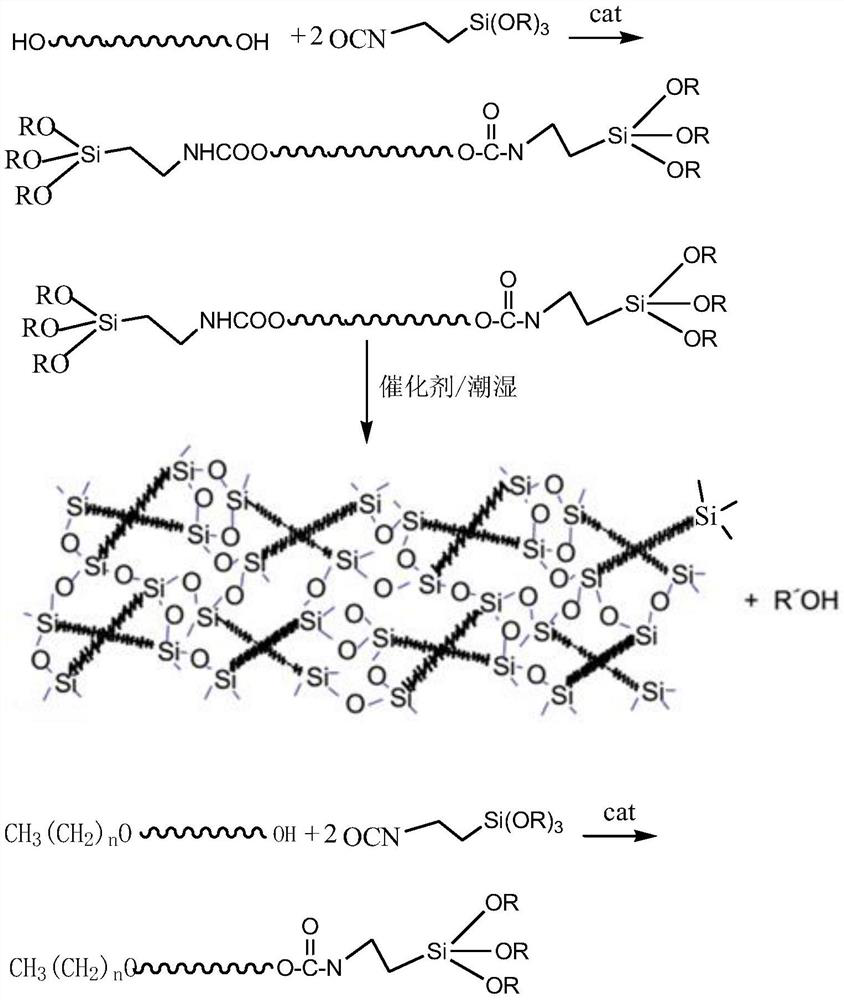

[0022] Concrete reaction formula is as follows:

[0023]

[0024] In the above method, the weight ratio of the monoalcohol pol...

Embodiment 1

[0028] In a 2.5L high-pressure stirred reactor, adding molecular weight is 400 propylene glycol polyoxypropylene ether 92g and molecular weight is 300 butanol polyoxypropylene ether 8g and double metal complex catalyst DMC 0.026g, vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, under the vacuum degree ≥ -0.096MPa, heat up and dehydrate while vacuuming. When the temperature is 120°C, keep warm and dehydrate for 1 hour. After dehydration, 1175 g of propylene oxide was added. Control the reaction temperature at 110-130°C, and the pressure in the reactor at -0.05-0.40MPa. After the addition, keep warm and continue the reaction until the pressure stops dropping. After the reaction is completed, vacuum degassing, keep the vacuum ≥-0.098MPa for 10 minutes, then cool down and discharge to obtain the polyether product for low modulus sealant.

[0029] Product indicators: The molecular weight of the gel chromatography test is 4980, and th...

Embodiment 2

[0034] In a 2.5L high-pressure stirred reactor, adding molecular weight is 800 glycerol polyoxypropylene ether 115g and molecular weight is 1200 alcohol polyoxypropylene ether 20g and multi-metal complex catalyst MMC 0.060g, vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, under the vacuum degree ≥ -0.096MPa, heat up and dehydrate while vacuuming. When the temperature rises to 120°C, keep warm and dehydrate for 1 hour. After the dehydration is completed, add 1230g of propylene oxide, control the reaction temperature at 120-150°C, and the pressure in the reactor at -0.05-0.40MPa. After the addition, keep warm and continue the reaction until the pressure no longer drops. After the reaction is completed, vacuum degassing, when the vacuum degree ≥ -0.098MPa is kept for 10 minutes, the temperature is lowered and the material is discharged to obtain the polyether product for low modulus sealant.

[0035] Product indicators: The molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com