High-effective filter layer body for a dust mask

A filter layer, coffee carbon fiber technology, applied in applications, protective clothing, protective equipment, etc., can solve the problems of reducing the service life of masks, inability to disassemble parts for cleaning or replacement, and not having filter use, etc., to reduce the cost of raw materials and feel comfortable. The effect of slipping and preventing the passage of fine dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

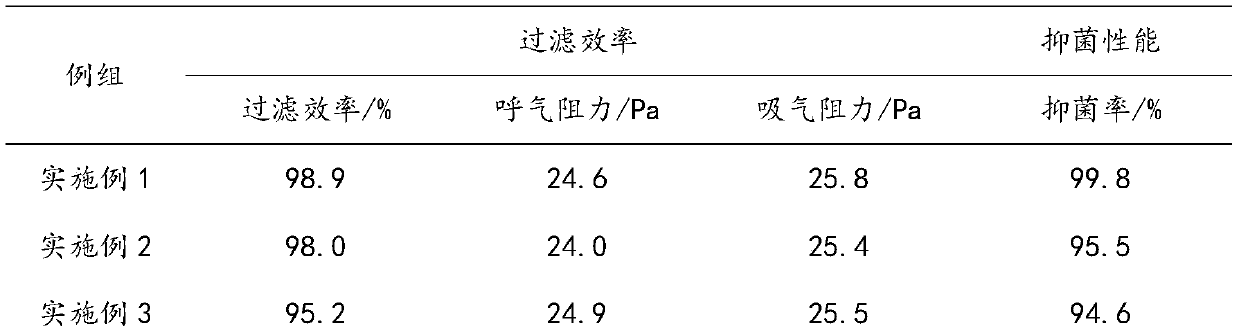

Embodiment 1

[0093] Embodiment 1: a kind of high-efficiency dust-proof mask is used filter layer body structure:

[0094] The present embodiment provides a filter layer body for a high-efficiency dust-proof mask, which has a structure comprising the following layers arranged in sequence from outside to inside:

[0095] Non-woven outer layer, which is 30g / m 2 non-woven fabric layer;

[0096] Aloe mannan porous film layer;

[0097] Composite filter layer;

[0098] Aloe mannan nanoporous inner membrane layer;

[0099] Pure cotton gauze inner layer, it comprises 2 layers, and described pure cotton gauze grammage is 40g / m 2 .

[0100] Specifically, the aloe mannan porous film layer described in this example was prepared through the following steps:

[0101] 1) Take aloe mannan powder and ultrapure water according to the ratio of 1.5:100;

[0102] 2) Place the aloe mannan solution in a constant temperature water bath at 44°C, and stir with a magnetic stirrer at 500r / min for 60min;

[010...

Embodiment 2

[0132] Embodiment 2: another kind of high-efficiency dustproof mask is used filter layer body structure:

[0133] The present embodiment provides another kind of filter body structure for high-efficiency dust-proof masks, which is basically the same as Embodiment 1, except that the filter layer structure of the present embodiment does not contain aloe mannan porous film layer; the remaining structures And method are all identical with embodiment 1.

Embodiment 3

[0134] Embodiment 3: Another kind of high-efficiency dustproof mask is used filter layer body structure:

[0135] The present embodiment provides another filter layer body structure for a high-efficiency dustproof mask, which is basically the same as Embodiment 1, except that the filter layer body structure of the present embodiment does not contain a composite filter layer; all the other structures and methods are the same as Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com