Polymer film PEFE with D-A-D structure and preparation method and application thereof

A D-A-D, structural polymer technology, applied in the direction of hybrid capacitor electrolyte, etc., to achieve the effect of high specific capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

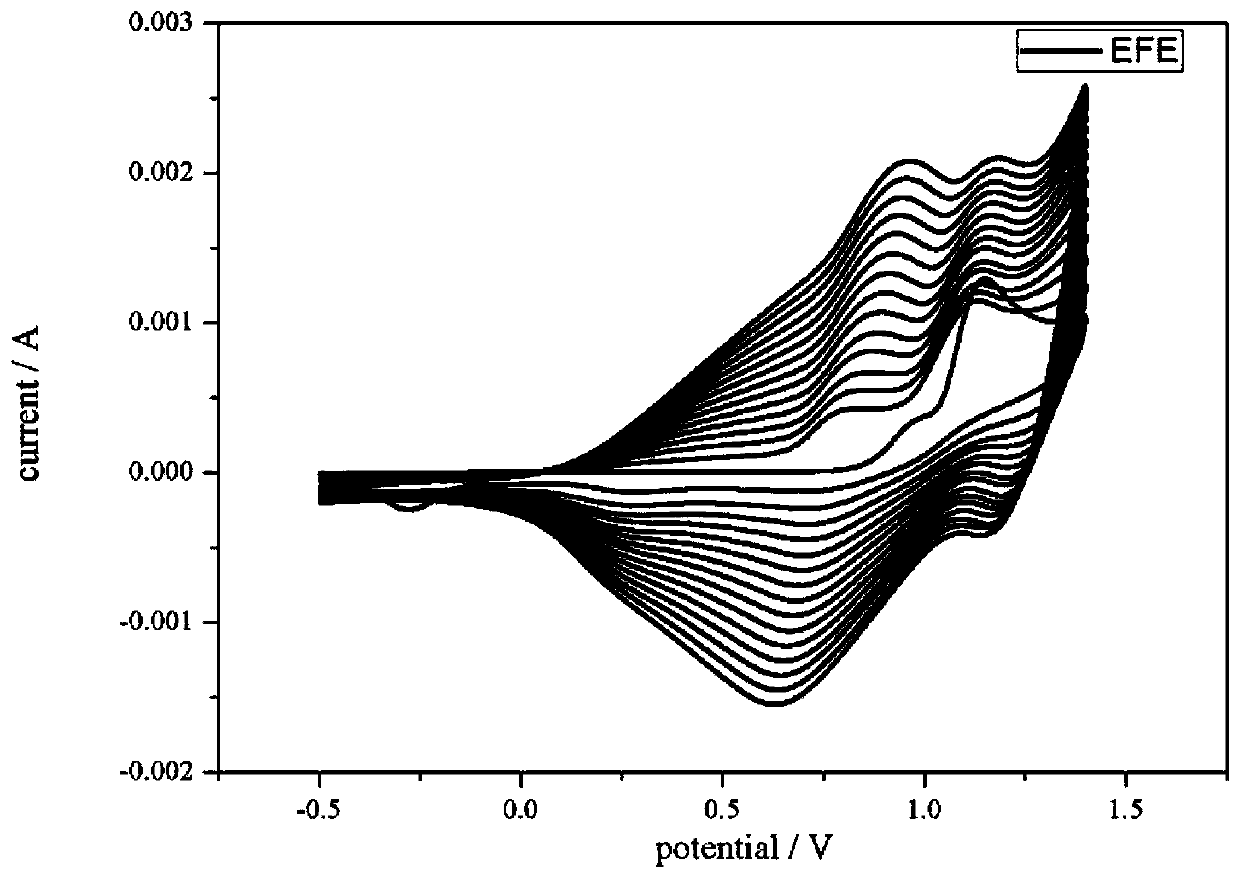

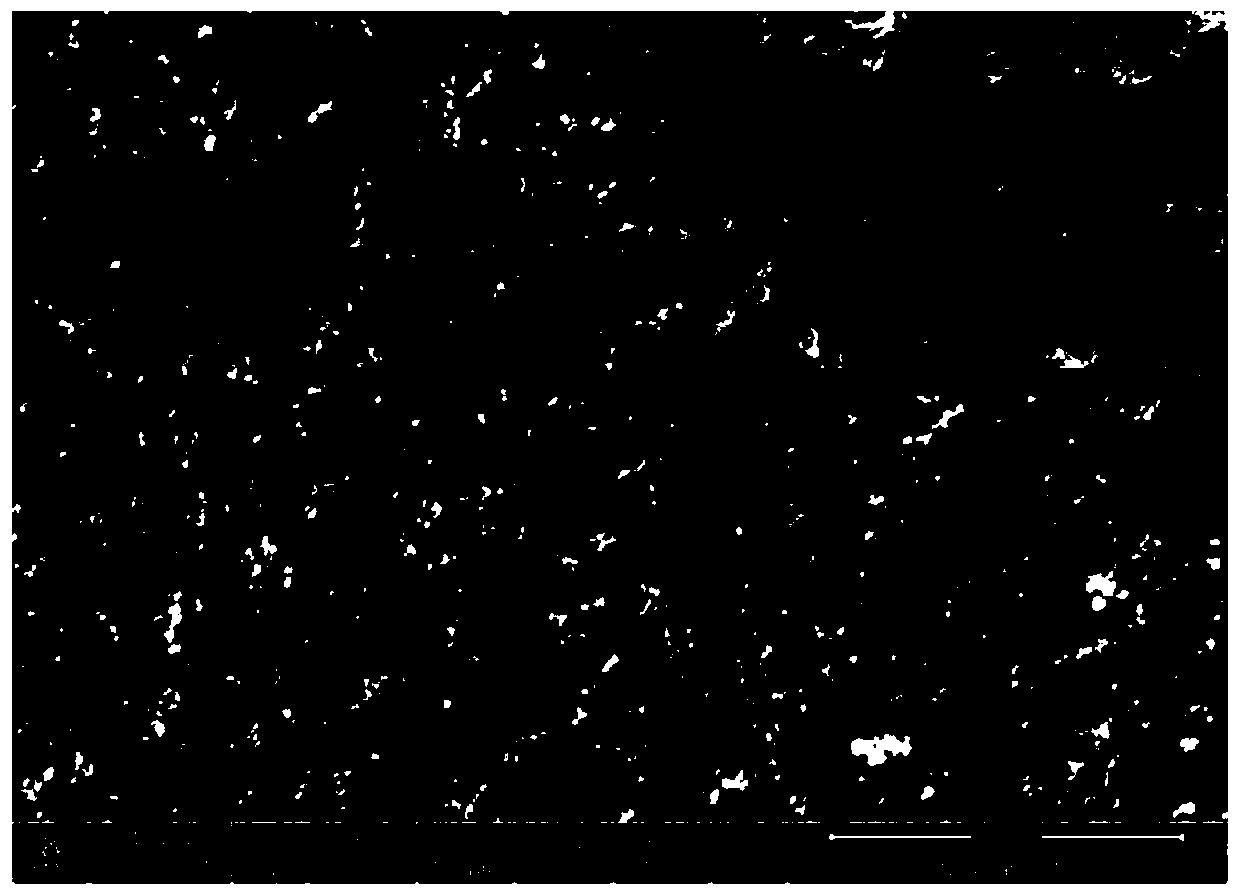

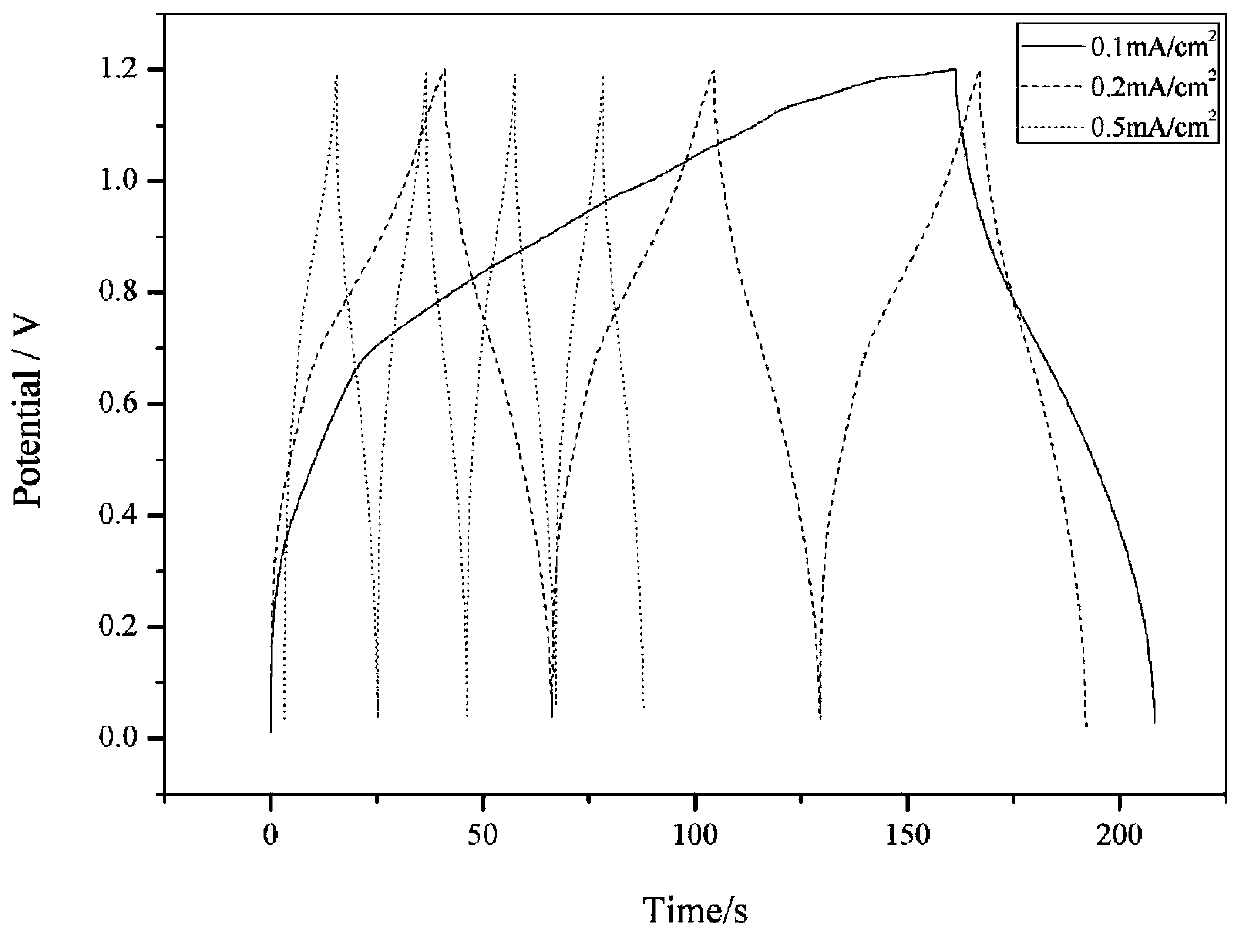

[0027] refer to Figure 1 to Figure 5 , a D-A-D structure polymer film PEFE, prepared according to the following method:

[0028] (1) Synthesis of monomeric EFE

[0029] For 3,4-ethylenedioxythiophene (EDOT) tinning, EDOT (6mmol, 0.852g) was dissolved in dry tetrahydrofuran (40mL) at -78°C under N 2 Under the atmosphere, slowly add n-butyllithium (6.6mmol, 4.125mL, 1.6M) dropwise, slowly raise the temperature to -40°C, stir for 1h, then cool down to -78°C, slowly add dropwise tributyltin chloride (7.2mmol , 2.347g), and stirred at room temperature for 8h, filtered through a neutral alumina column to remove solid impurities, and obtained the product tributyl (2,3-dihydro[3,4-b][1,4]dioxin -5-yl) stannane, 2,7-dibromo-9 fluorenone (3mmol, 1.014g), tributyl(2,3-dihydro[3,4-b][1,4]diox In-5-yl) stannane (6mmol, 2.593g) and bistriphenylphosphine palladium dichloride (0.025mmol, 0.01755g) in N 2 Dissolve in 50ml of dry toluene under atmosphere, heat to 110°C and keep reflux for ...

Embodiment 2

[0035] A D-A-D structure polymer membrane PEFE is prepared according to the following method:

[0036] (1) Synthesis of monomeric EFE

[0037] For 3,4-ethylenedioxythiophene (EDOT) tinning, EDOT (6mmol, 0.852g) was dissolved in dry tetrahydrofuran (40mL) at -78°C under N 2 Under the atmosphere, slowly add n-butyllithium (6.6mmol, 4.125mL, 1.6M) dropwise, slowly raise the temperature to -40°C, stir for 1h, then cool down to -78°C, slowly add dropwise tributyltin chloride (7.2mmol , 2.347g), and stirred at room temperature for 8h, filtered through a neutral alumina column to remove solid impurities, and obtained the product tributyl (2,3-dihydro[3,4-b][1,4]dioxin -5-yl) stannane. 2,7-Dibromo-9-fluorenone (3mmol, 1.014g), tributyl(2,3-dihydro[3,4-b][1,4]dioxin-5-yl)stannane (6mmol, 2.593g) and bistriphenylphosphine palladium dichloride (0.025mmol, 0.01755g) in N 2 Dissolve in 50ml of dry toluene under atmosphere, heat to 110°C and keep reflux for 36 hours. After the system w...

Embodiment 3

[0043] A D-A-D structure polymer membrane PEFE is prepared according to the following method:

[0044] (1) Synthesis of monomeric EFE

[0045] For 3,4-ethylenedioxythiophene (EDOT) tinning, EDOT (6mmol, 0.852g) was dissolved in dry tetrahydrofuran (40mL) at -78°C under N 2 Under the atmosphere, slowly add n-butyllithium (6.6mmol, 4.125mL, 1.6M) dropwise, slowly raise the temperature to -40°C, stir for 1h, then cool down to -78°C, slowly add dropwise tributyltin chloride (7.2mmol , 2.347g), and stirred at room temperature for 8h, filtered through a neutral alumina column to remove solid impurities, and obtained the product tributyl (2,3-dihydro[3,4-b][1,4]dioxin -5-yl) stannane. 2,7-Dibromo-9-fluorenone (3mmol, 1.014g), tributyl(2,3-dihydro[3,4-b][1,4]dioxin-5-yl)stannane (6mmol, 2.593g) and bistriphenylphosphine palladium dichloride (0.025mmol, 0.01755g) in N 2 Dissolve in 50ml of dry toluene under atmosphere, heat to 110°C and keep reflux for 36 hours. After the system w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com