Modified carbon fiber reinforced phenolic resin-based composite material and preparation thereof

A phenolic resin and fiber reinforcement technology is applied in the field of modified carbon fiber reinforced phenolic resin-based composite materials and their preparation, which can solve problems such as mechanical properties decline, and achieve good formability, low cost, good interface bonding performance and anti-oxidative burning. effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific preparation steps of a modified carbon fiber reinforced phenolic resin-based composite material are as follows:

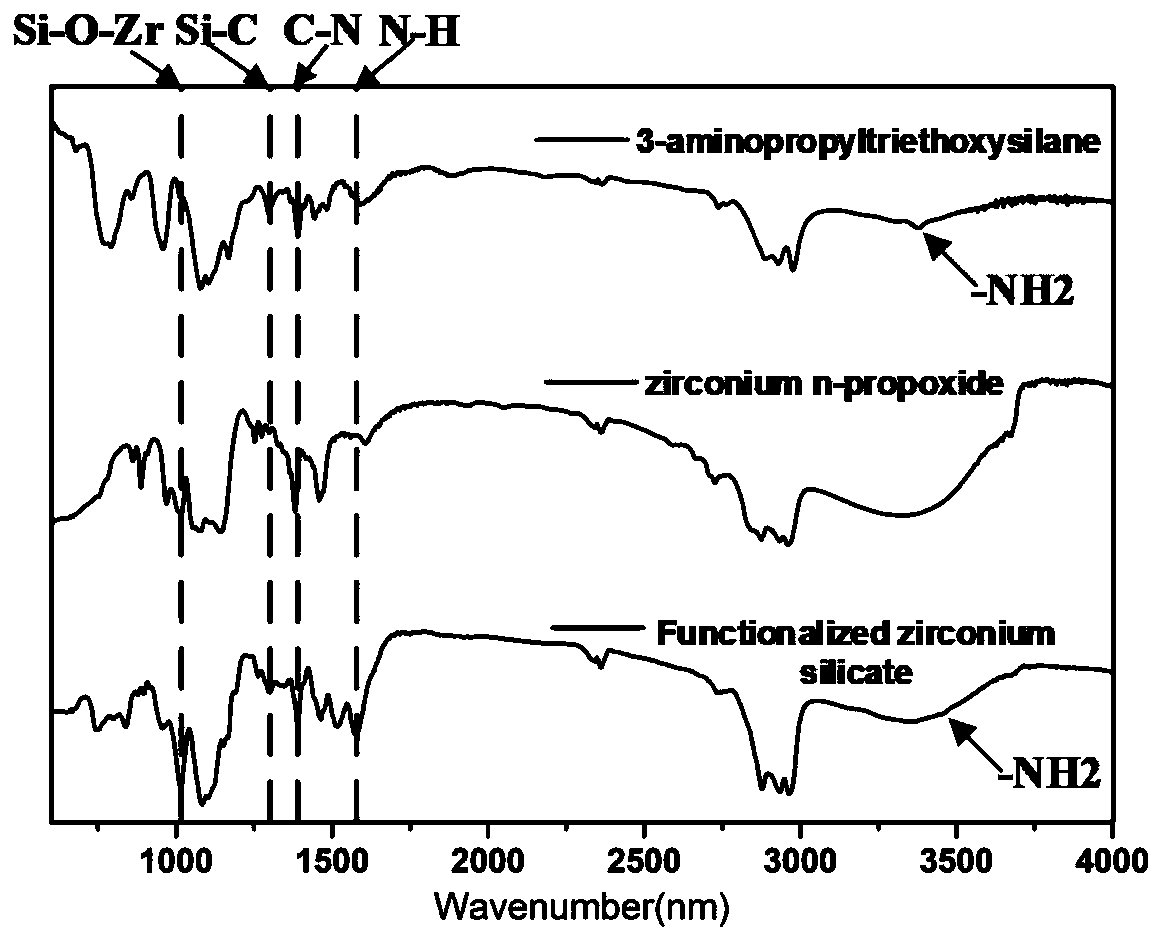

[0033] (1) Add 20mL of 3-aminopropyltriethoxysilane, 33mL of zirconium n-propoxide solution and 10mL of absolute ethanol into the flask, then heat the flask in an oil bath and reflux at 110°C for 20h, After standing and aging for 5 hours, an organic-inorganic hybrid zirconium silicate sol was obtained;

[0034] (2) Place 70g of carbon fiber cloth in an inert atmosphere (argon) at 800°C for desizing treatment, and then oxidize the carbon fiber cloth with nitric acid (60wt%) at 80°C for 2 hours, and then wash it with deionized water To PH=7, then dry to obtain a carbon fiber cloth with -COOH on the surface;

[0035] (3) The organic-inorganic hybrid zirconium silicate sol obtained in step (1) is oxidized in step (2) according to the mass ratio of organic-inorganic hybrid zirconium silicate sol and carbon fiber cloth by air spraying The two surfac...

Embodiment 2

[0042] The specific preparation steps of a modified carbon fiber reinforced phenolic resin-based composite material are as follows:

[0043] (1) Add 30mL of γ-glycidyl etheroxypropyltrimethoxysilane, 51mL of zirconium n-propoxide solution and 10mL of absolute ethanol into the flask, then heat the flask in an oil bath, and reflux at 110°C for 20h , after standing and aging for 5 hours, an organic-inorganic hybrid zirconium silicate sol was obtained;

[0044] (2) Place 70g of carbon fiber cloth in an inert atmosphere (argon) at 800°C for desizing treatment, and then oxidize the carbon fiber cloth with nitric acid (60wt%) at 80°C for 2 hours, and then wash it with deionized water To PH=7, then dry to obtain a carbon fiber cloth with -COOH on the surface;

[0045] (3) The organic-inorganic hybrid zirconium silicate sol obtained in step (1) is oxidized in step (2) according to the mass ratio of organic-inorganic hybrid zirconium silicate sol and carbon fiber cloth by air spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com