Efficient pelleting method of tobacco seeds

A tobacco seed and pelletizing technology, applied in the direction of seed coating/seed dressing, coating, etc., can solve the problems of backward processing machinery and technology, influence of seed quality, unsatisfactory granulation shape, etc., and achieve standardization and Standardize, eliminate the influence of human factors, and facilitate the effect of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] S100: Take 100g of Yunyan 87 with an average length of 0.6-0.8mm of bare seeds, use a 30-mesh sieve to remove impurities larger than tobacco seeds, and use a 50-mesh sieve to remove impurities smaller than seeds, small seeds and flat seeds , then winnowed, and then sieved with a 0.5mm mesh sieve to obtain plump and uniform seeds under the sieve as pre-coated seeds for later use.

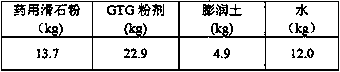

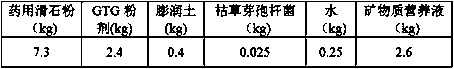

[0046] S200: mix 85% talcum powder, 10% GTG powder, and 5% kaolin by mass to obtain a powder for nucleating coating; The mass ratio is mixed to obtain the powder for pelletizing and coating.

[0047] S300: mixing the colorant and water at a mass ratio of 1:10 to obtain a colorant slurry.

[0048] S400: Potassium dihydrogen phosphate 5.82%, magnesium sulfate 21.07%, potassium nitrate 21.63%, calcium nitrate 50.54%, edetate disodium 0.32%, copper sulfate 0.24%, manganese chloride 0.08%, chlorine 0.05% zinc chloride, 0.11% sodium molybdate, 0.02% copper chloride dihydrate, and 0.12% boric acid ...

Embodiment 2

[0055] S100: Take 100g of Yunyan 87 with an average length of 0.6-0.8mm of bare seeds, use a 40-mesh sieve to remove impurities larger than tobacco seeds, and use a 50-mesh sieve to remove impurities smaller than seeds, small seeds and flat seeds , then winnowed, and then sieved with a 0.5mm mesh sieve to obtain plump and uniform seeds under the sieve as pre-coated seeds for later use.

[0056] S200: mix 65% talcum powder, 30% GTG powder, and 5% kaolin by mass to obtain a powder for nucleating coating; The mass ratio is mixed to obtain the powder for pelletizing and coating.

[0057] S300: mixing the colorant and water at a mass ratio of 1:15 to obtain a colorant slurry.

[0058] S400: Potassium dihydrogen phosphate 5.82%, magnesium sulfate 21.07%, potassium nitrate 21.63%, calcium nitrate 50.54%, edetate disodium 0.32%, copper sulfate 0.24%, manganese chloride 0.08%, chlorine 0.05% of zinc chloride, 0.11% of sodium molybdate, 0.02% of copper chloride dihydrate, and 0.12% of...

experiment example 1

[0071] The coated finished tobacco seeds obtained in Example 1 were used as experimental materials, and the coated pelleted seeds of Comparative Example 1 were used as controls. The seeds after pelleting were carried out germination experiment respectively, and the process is as follows:

[0072] 1. Put 2 layers of wet filter paper in a petri dish, place 100 pelleted seeds evenly on each petri dish and cover it, and germinate the pelleted seeds at 25°C and 12h / 12h light / dark conditions, keep The filter paper is moist.

[0073] 2. Record the number of germinated seeds every day from the 3rd day (germinated when the radicle length is greater than or equal to the seed length), and record continuously for 14 days until the end of germination.

[0074] 3. After germination, calculate the germination potential and germination rate of the pelleted seeds.

[0075] Germination potential (%) = (Number of seeds normally germinated in 7 days / Number of seeds tested) × 100%,

[0076] Ger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com