Cr<3+> ion-activated near-infrared fluorescent powder, preparation method and application thereof

A phosphor and near-infrared technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high melting point, luminescence quenching, poor stability, etc., and achieve the effects of simple synthesis process, high luminous efficiency, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the chemical formula NaAl 0.95 Cr 0.05 VPO 7 , where x is Cr 3+ Doping instead of Al 3+ The molar ratio of 0.001≤x≤0.1. The sample of the present invention adopts the stoichiometric ratio of elements Na, Al, Cr, P and V, respectively weighs sodium carbonate Na 2 CO 3 : 0.530 g, aluminum oxide Al 2 o 3 : 0.484 g, chromium oxide Cr 2 o 3 : 0.038 g, ammonium metavanadate NH 4 VO 3 : 1.170 g, monoammonium phosphate NH 4 h 2 PO 4 : 1.150 g. Add acetone to the weighed raw materials for wet grinding, so as to mix evenly, and the obtained mixture is calcined for the first time under the air atmosphere, the calcining temperature is 300 ° C, and the calcining time is 1 hour; the calcined samples are ground evenly, and the calcined samples are Calcining for the second time, the calcination temperature is 750°C, and the calcination time is 4 hours to obtain a Cr 3+ Ion-activated near-infrared phosphors.

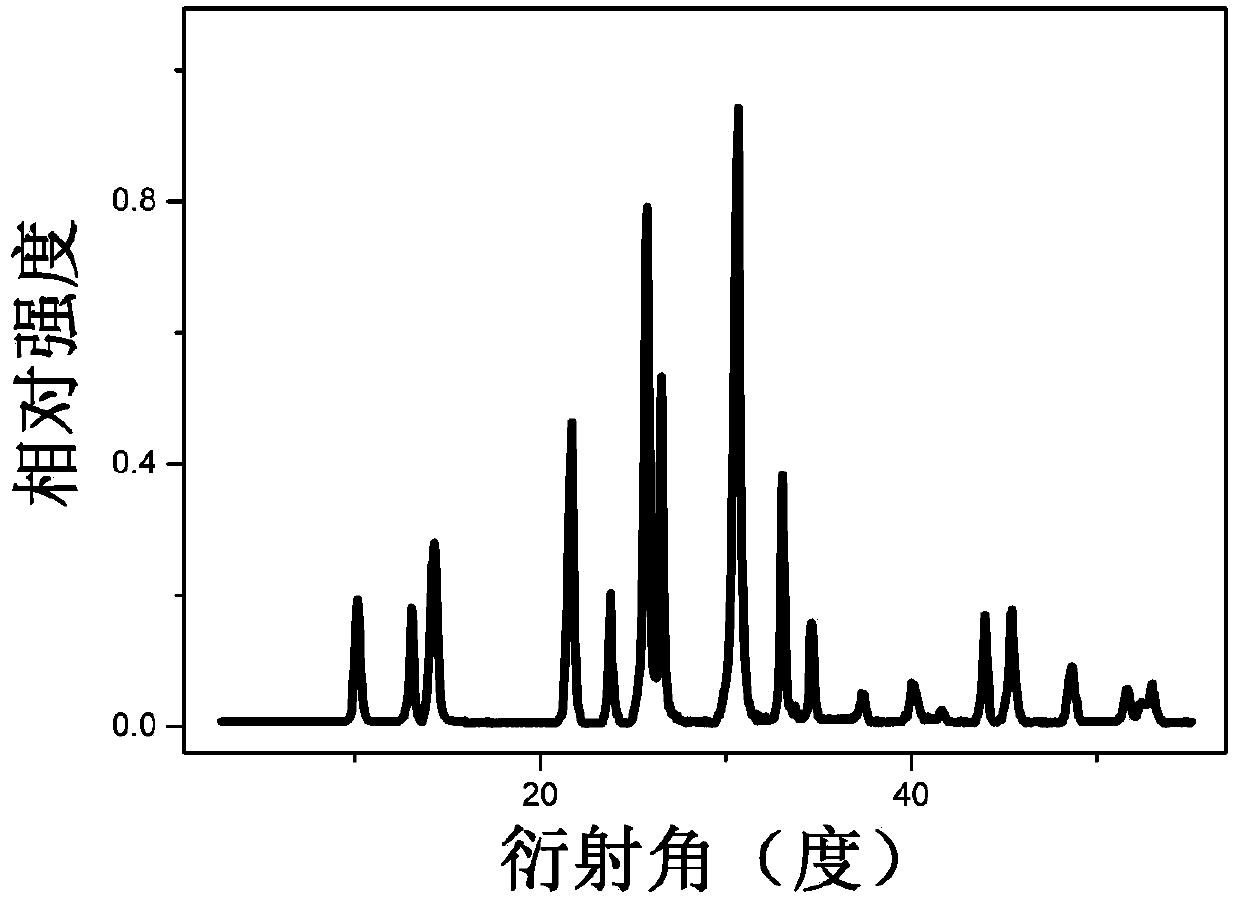

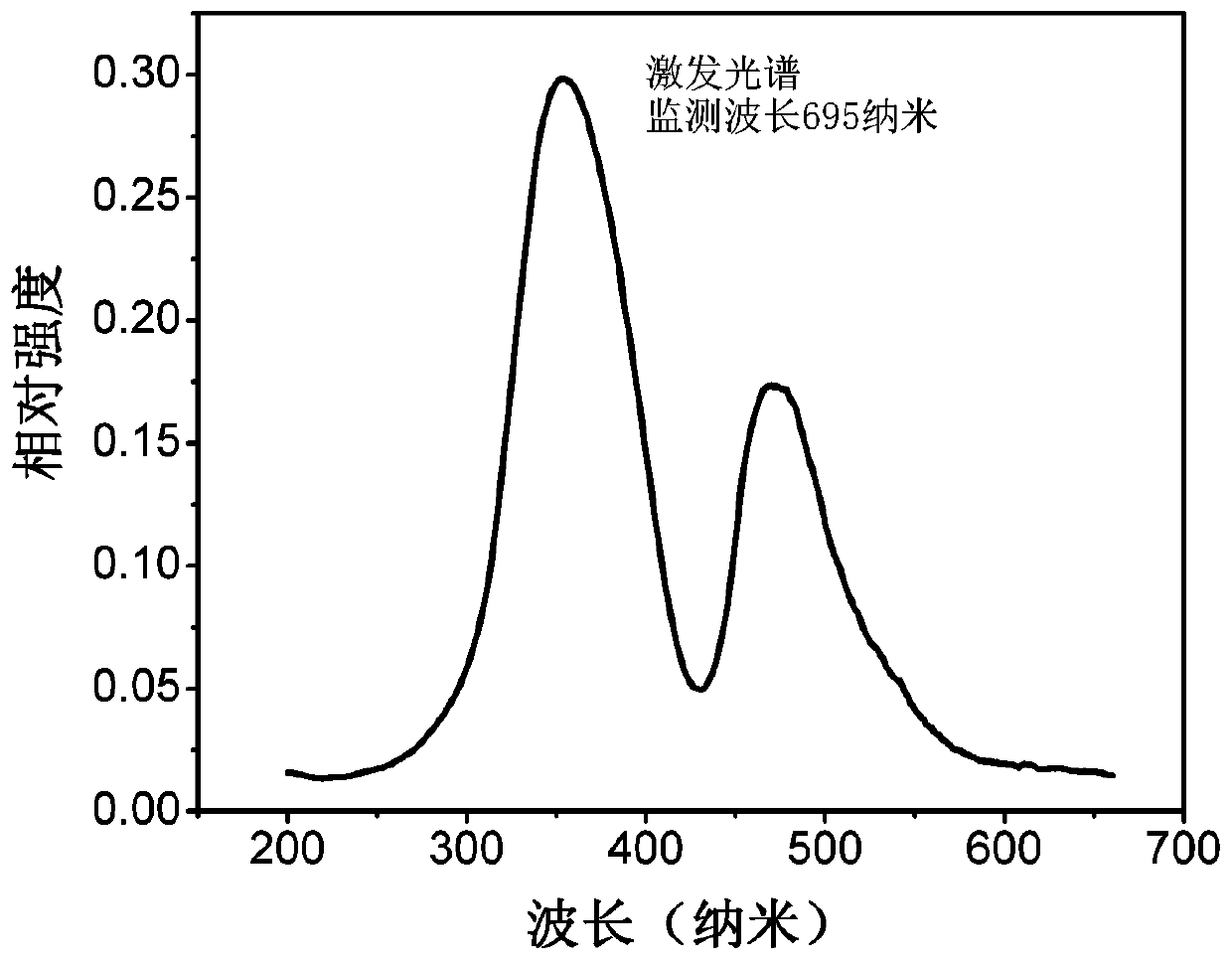

[0031] See attached figure 1 , is the X-ray po...

Embodiment 2

[0037] According to the chemical formula NaAl 0.999 Cr 0.001 VPO 7 , where x is Cr 3+ Doping instead of Al 3+ The molar ratio of 0.001≤x≤0.1. The sample of the present invention adopts the stoichiometric ratio of elements Na, Al, Cr, P and V, respectively weighs sodium hydroxide NaOH: 0.400 grams, aluminum oxide Al 2 o 3 : 0.509 g, chromium oxide Cr 2 o 3 : 0.076 g, vanadium pentoxide V 2 o 5 : 0.909 g, Phosphate H 3 PO 4 : 0.980 g. Mix the weighed raw materials and add acetone to carry out wet grinding, so as to mix evenly, and the obtained mixture is calcined for the first time under the air atmosphere, the calcining temperature is 400 ° C, and the calcining time is 3 hours; Calcining for the second time, the calcination temperature is 820°C, and the calcination time is 5 hours to obtain Cr 3+ Ion-activated near-infrared phosphors.

[0038] The structure, morphology, excitation spectrum, emission spectrum, and luminescence attenuation of the phosphor sample pre...

Embodiment 3

[0040] According to the chemical formula NaAl 0.9 Cr 0.1 VPO 7 , where x is Cr 3+ Doping instead of Al 3+ The molar ratio of 0.001≤x≤0.1. The sample of the present invention adopts the stoichiometric ratio of elements Na, Al, Cr, P and V, respectively weighs sodium sulfate Na 2 SO 4 : 0.710 g, aluminum hydroxide Al(OH) 3 : 0.702 grams, chromium nitrate Cr (NO 3 ) 3 9H 2 O: 0.400 g, vanadium pentoxide V 2 o 5 : 0.909 g, Phosphate H 3 PO 4 : 0.980 g. After mixing the weighed raw materials, add acetone for wet grinding, so as to mix uniformly, and the obtained mixture is calcined for the first time under air atmosphere, the calcining temperature is 450 ° C, and the calcining time is 3.5 hours; the calcined samples are ground evenly, and the The second calcination under air atmosphere, the calcination temperature is 800 ℃, and the calcination time is 6 hours, to obtain a Cr 3+ Ion-activated near-infrared phosphors.

[0041] The structure, morphology, excitation spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com