Red mud fly ash system low-temperature flue gas desulfurization and denitrification absorbent and preparation method thereof

A technology for desulfurization, denitrification, and low-temperature flue gas, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., and can solve the urgent problems of acid waste gas emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

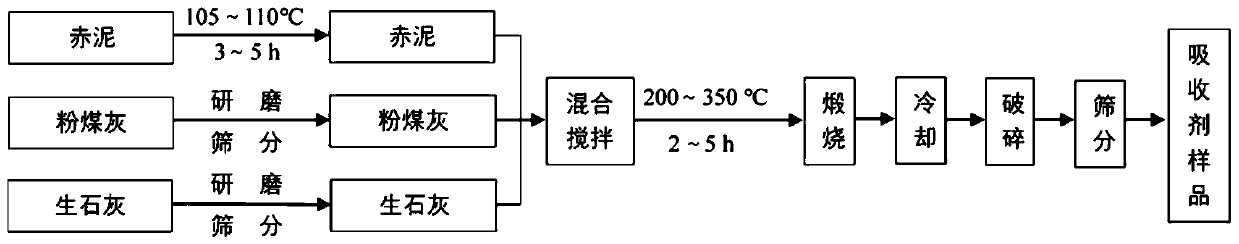

[0070] like figure 1 Shown, the present invention relates to a kind of preparation method of red mud fly ash system low-temperature flue gas desulfurization and denitrification absorbent, described method comprises the following steps:

[0071] Step (1): Weigh a certain amount of red mud, fly ash and granular quicklime respectively, dry the red mud at 105°C-110°C for 3-5 hours, grind the granular quicklime and flyash separately, and Sieve to 50-150 mesh and set aside; among them, the mass ratio of red mud, fly ash and quicklime is preferably: 7:2:1-5:4:1;

[0072] In step (2), put the spare red mud, fly ash and quicklime in the step (1) into the container, preferably a beaker or a mixer in the above mass ratio, stir and mix well, and after the raw materials are completely reacted and formed, put The sample is transferred to a heating furnace, preferably a muffle furnace or a roasting furnace, calcined at 200-350°C for 2-5 hours, then taken out and cooled;

[0073] Step (3): ...

Embodiment 1

[0082] Weigh a certain amount of red mud, fly ash and granular quicklime respectively, dry the red mud at 105°C-110°C for 5 hours, grind the granular quicklime and flyash separately, and sieve to 50-150 mesh The mass ratio of red mud, fly ash and unslaked lime is: 7:2:1; According to this ratio, add three kinds of raw materials in the beaker, seal, fully mix and stir, after the raw materials react completely and form, transfer the sample to the beaker. After calcining at 200-350°C for 3 hours in a Furnace, take it out to cool, crush, grind, and then sieve with a 200-300-mesh sampling sieve to obtain the final absorbent sample.

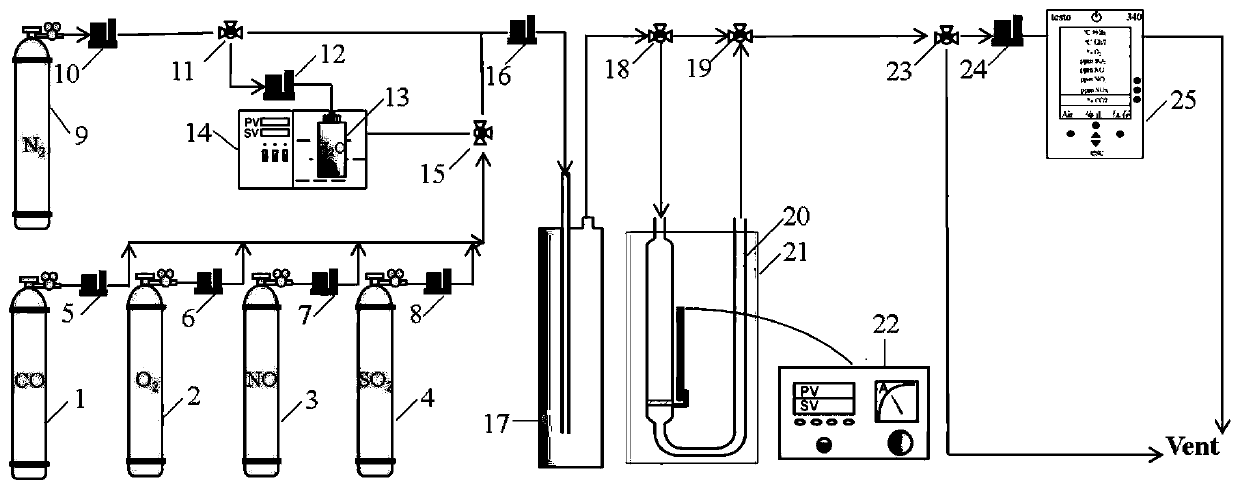

[0083] Simultaneous desulfurization and denitrification performance evaluation of red mud fly ash absorbent: put the treated red mud fly ash system absorbent into fixed bed reactor 20 (the fixed bed reactor is made of quartz glass, with an inner diameter of 10 mm, and the absorbent is accumulated Height is 15mm), first use inert gas N 2 After purging ...

Embodiment 2

[0085] Weigh a certain amount of red mud, fly ash and granular quicklime respectively, dry the red mud at 105°C-110°C for 4 hours, grind the granular quicklime and flyash separately, and sieve to 50-150 mesh ; The mass ratio of red mud, fly ash and quicklime is: 6:3:1; according to this ratio, add a certain amount of three kinds of raw materials into the mixer, fully mix and stir, and after the raw materials are completely reacted and formed, transfer the sample to put into a roasting furnace, calcined at 300°C for 4 hours, cooled, crushed, ground, and then sieved with a sampling sieve with a mesh size of 150-250 mesh to obtain the final absorbent sample.

[0086] The red mud fly ash system absorbent was applied to the 3×220t / h boiler flue gas ultra-low emission renovation project of Nantun Electric Power Branch of Yankuang Group Co., Ltd. Entrance SO 2 The concentration is 800mg / Nm 3 , the inlet NOx concentration is 200mg / Nm 3 . The flue gas temperature is 150°C and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com