A method for direct hydrogen production by microwave catalytic methane conversion

A microwave catalyzed methane, direct technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory methane conversion rate, hydrogen yield, poor catalyst anti-coking ability and poor stability and other problems, to achieve the effects of reduced apparent activation energy, high catalytic activity and selectivity, and poor anti-carbon deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

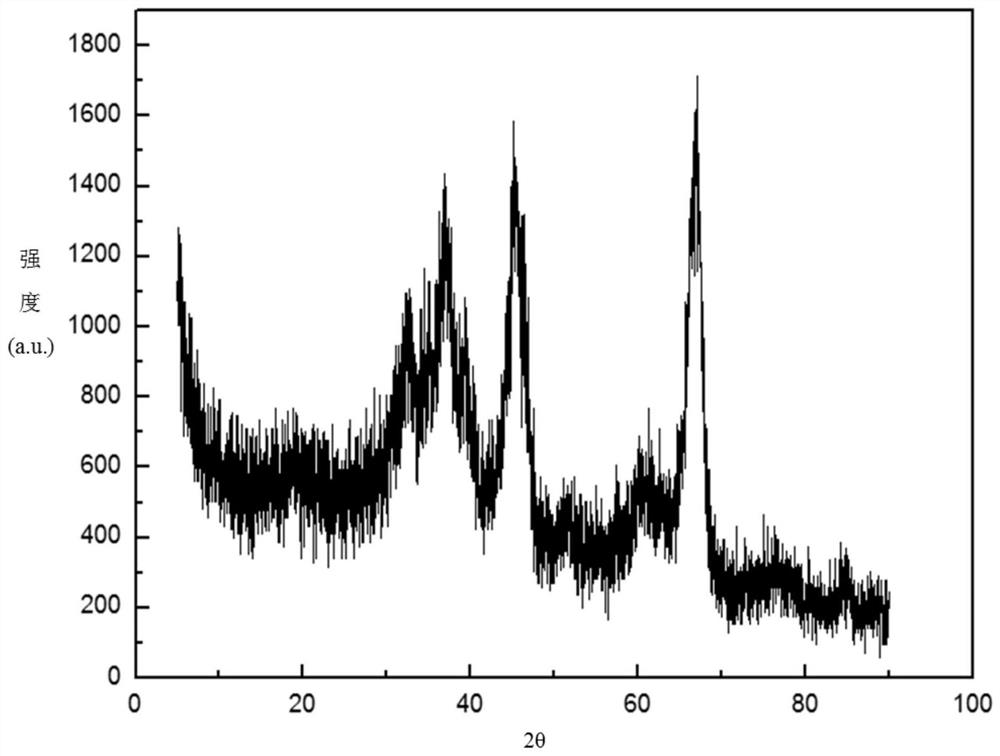

[0023] γ-Al 2 o 3 Add 80ml of isopropanol, sonicate for 60min to get treated γ-Al 2 o 3 and isopropanol mixture. Under stirring conditions, the ammonium molybdate solution was added dropwise to the above solution, stirred for 10 minutes, and then ultrasonicated for 30 minutes. Stirring in a water bath at 40°C for 8h, the resulting product was dried overnight in a drying oven at 110°C, and then calcined in a muffle furnace at 500°C for 4h to obtain the composite carrier MoO 3 / γ-Al 2 o 3 . Put the above composite carrier into the solution containing 20% CH 4 / H 2 (volume ratio) carbonization in a tube furnace to obtain 10% Mo 2 C / γ-Al 2 o 3 (Mo in the composite carrier 2 The content of C is 10wt%). Take 0.261g nickel nitrate hexahydrate and dissolve it in 10ml water, take 1g Mo 2 C / γ-Al 2 o 3 The composite carrier was placed in 40ml of isopropanol and ultrasonicated for 1h. The above solution was added dropwise to Mo 2 C / γ-Al 2 o 3 complex carrier and isop...

Embodiment 2

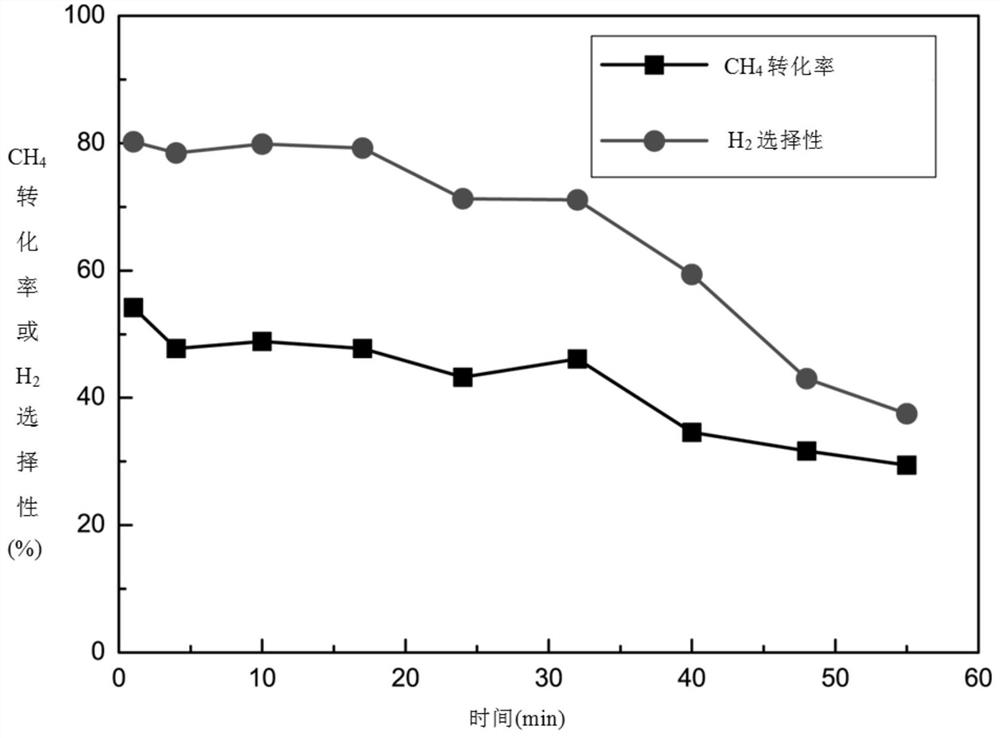

[0025] The microwave catalyst obtained according to Example 1 is used to catalyze the direct conversion of methane to hydrogen production, and the specific steps are as follows:

[0026] 1) Take a certain amount of Ni / Mo 2 C / γ-Al 2 o 3 The catalyst is placed in a microwave reactor device, and N 2 The flow rate was 80ml / min and the air was purged for 15min to remove the air in the reactor. Set the microwave power to 300-900W, start the microwave device, set the reaction temperature to 650°C, start the reaction device, and the instrument starts to heat up;

[0027] 2) When the reactor temperature reaches the set temperature, feed methane to start the reaction;

[0028] 3) Take the reacted gas with a gas sampling needle and pass it into an Agilent GC-7890A gas chromatograph for product analysis. Among them, TCD is used as a detector, N 2 As carrier gas, use Hayesep D packed column. Simultaneously record the reaction time and reaction temperature;

[0029] 4) According to ...

Embodiment 3

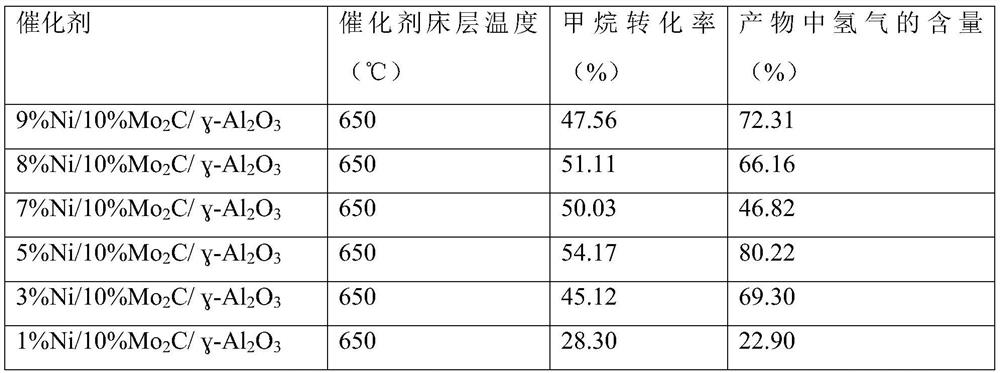

[0040] The consumption of catalyst is 1g, and catalyst bed temperature is 650 ℃, and reaction gas flow rate is 80ml / min, and reaction pressure is normal pressure, adopts 5%Ni / x%Mo 2 C / γ-Al 2 o 3 Composite nanostructured catalysts, investigating the same active components, different Mo 2 The effect of C loading on microwave catalytic methane conversion to hydrogen is shown in Table 3 for details.

[0041] table 3

[0042]

[0043] It can be seen from Table 3 that under microwave irradiation conditions, 5%Ni / x%Mo 2 C / γ-Al 2 o 3 Composite nanostructured catalysts for microwave-catalyzed methane reactions with 5% Ni / 10% Mo 2 C / γ-Al 2 o 3 The catalyst has the best effect, the methane conversion rate is 54.17%, and the hydrogen content in the product is 80.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com