Corynebacterium capable of realizing high yield of valine as well as construction method and application thereof

A technique of corynebacterium glutamicum and its construction method, which is applied in the field of corynebacteria with high valine production and its construction, and can solve the problems of poor fermentation performance, inability to meet large-scale industrial production, and low conversion rate of L-valine , to achieve the effect of increasing output, broad industrial application prospects, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

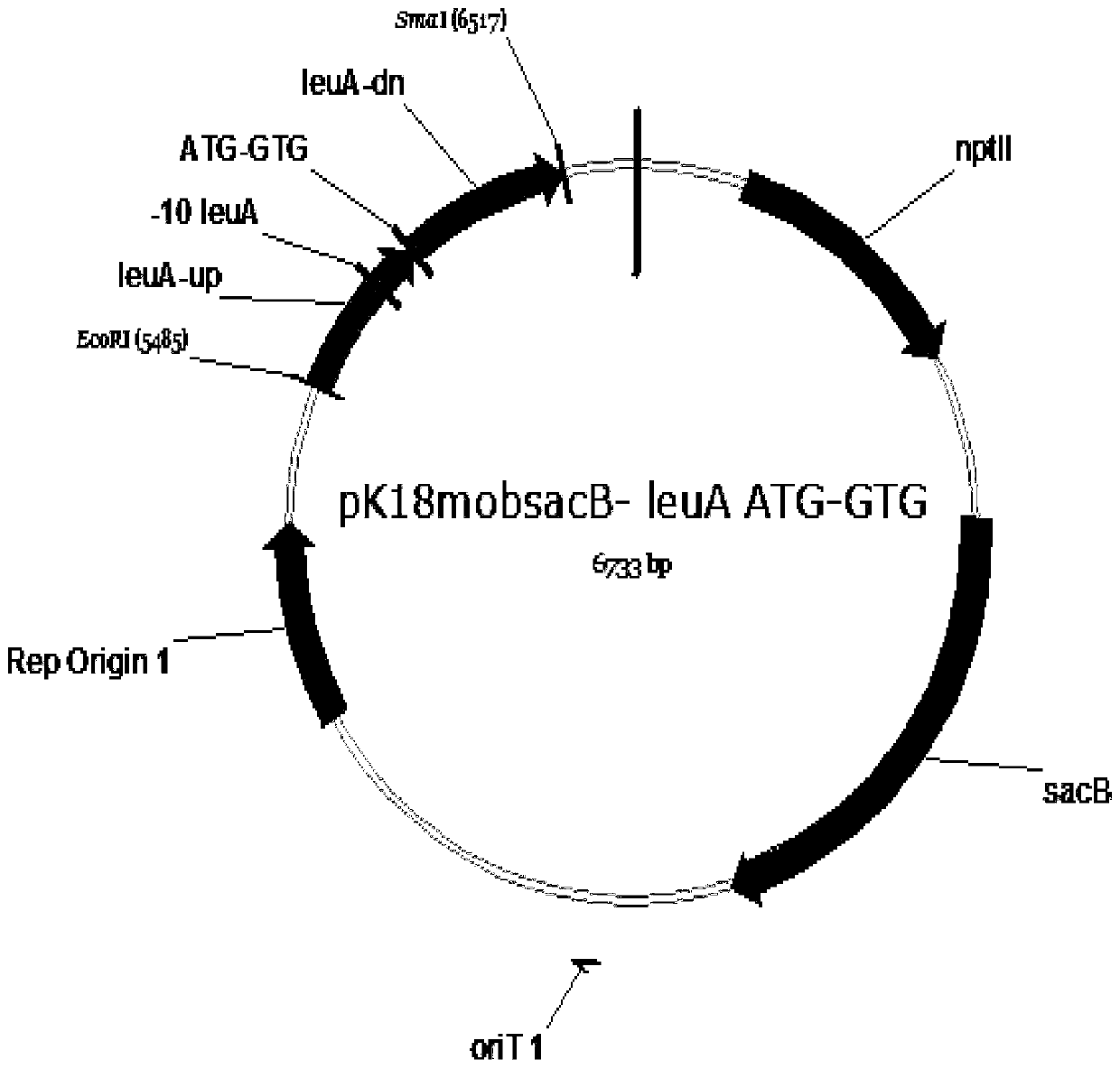

[0030] Example 1: Recombinant plasmid pK18mobsacB-leuA A1G Construction of and introduction of point mutations in MHZ-1012-2

[0031] (1) pK18mobsacB-leuA A1G Plasmid construction

[0032] Using the MHZ-1012-2 genome as a template, using leuA A1G -f1 / leuA A1G -r1 primer pair for PCR amplification to obtain the upstream fragment leuA A1G -up; take the MHZ-1012-2 genome as a template, take leuA A1G -f2 / leuA A1G -r2 primer pair for PCR amplification to obtain the downstream fragment leuA A1G -dn. with leuA A1G -up, leuA A1G -dn two-fragment mixture as template, with leuA A1G -f1 / leuA A1G -r2 primer pair for PCR amplification to obtain mutated leuA A1G fragment. leuA A1G The fragment was double-digested with EcoRI and SmaI, and pK18mobsacB was double-digested with the same enzymes. The two digestion products were ligated with T4DNA Ligase, transformed into Trans1T1 competent cells, and the recombinant plasmid pK18mobsacB-leuA was obtained A1G .

[0033] Table 1 Pr...

Embodiment 2

[0037] Example 2: Fermentation of L-valine genetically engineered bacteria to produce L-valine.

[0038] 1. Medium

[0039] Seed medium: corn steep liquor 2.5wt%, glucose 1.0wt%, ammonium sulfate 0.4wt%, magnesium sulfate 0.04wt%, potassium dihydrogen phosphate 0.1wt%, urea 0.1wt%, CaCO 3 0.5wt%, the balance is water, pH 7.2.

[0040] Fermentation medium: corn steep liquor 0.5wt%, glucose 12.0wt%, ammonium sulfate 4.0wt%, magnesium sulfate 0.04wt%, potassium dihydrogen phosphate 0.1wt%, CaCO 3 4wt%, VH 50μg / L, VB1·HCl 100μg / L, balance water, pH 7.2.

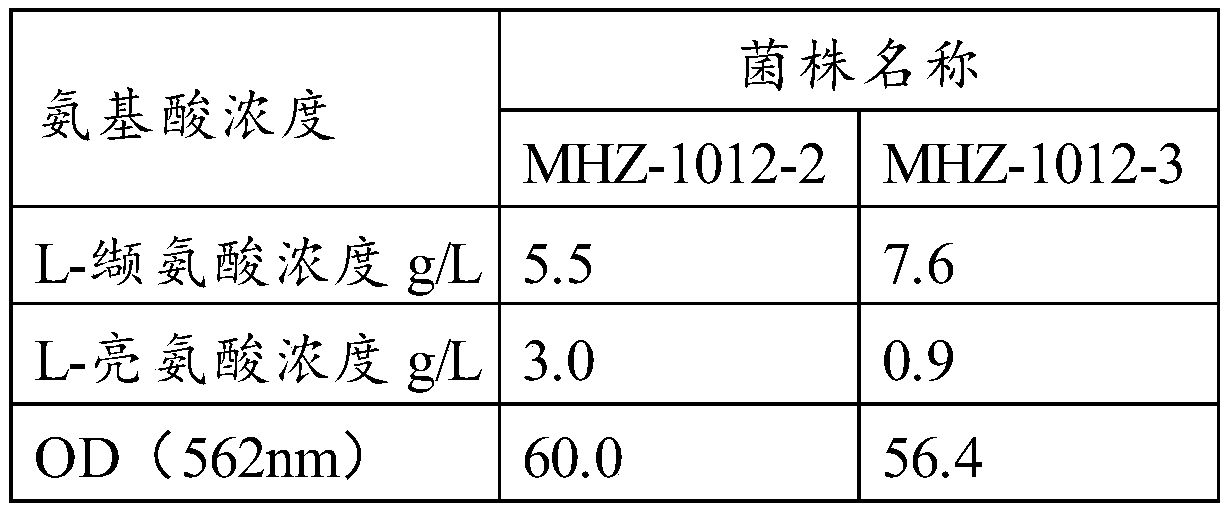

[0041] 2. Production of L-valine by MHZ-1012-3 shake flask fermentation

[0042] (1) Seed culture: Pick 1 loop of MHZ-1012-2 and MHZ-1012-3 slanted seeds and transfer them to a 500mL Erlenmeyer flask containing 20mL of seed medium, and shake at 33°C and 220r / min for 16-22h;

[0043] (2) Fermentation culture: Inoculate 2 mL of seed solution into a 500 mL Erlenmeyer flask containing 20 mL of fermentation medium, and culture a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com