Copper film alkaline polishing solution for low-technology node copper wiring

A technology of copper wiring and polishing liquid, which is applied in the field of copper film alkaline polishing liquid for copper wiring of low-tech nodes, can solve the problems of high R&D and production costs, and can not reduce the removal rate, and achieve low copper surface roughness and high removal rate Slow, fast removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

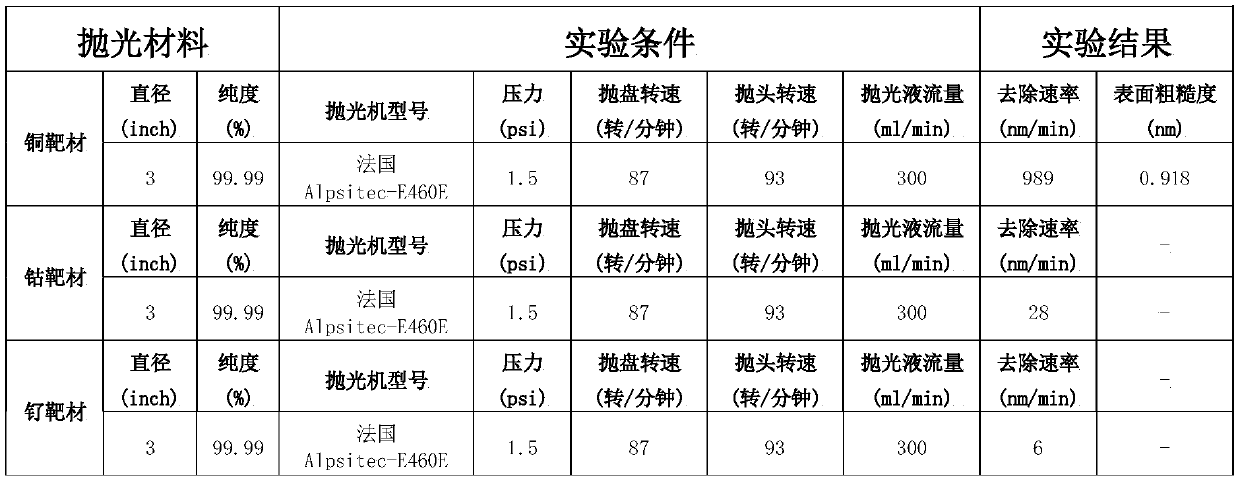

Embodiment 1

[0013] 1. Material ratio, based on the total weight of the mixture as 100, and the percentage of each material, SiO 2 10% silica sol with a particle size of 70-90nm 0.1 glycine 3 hydrogen peroxide 0.1 fatty alcohol polyoxyethylene ether 0.1 chitosan 0.01 potassium hydroxide 1 deionized water 95.69

[0014] 2. Material source

[0015] (1), SiO 2 10% silica sol with a particle size of 70-90nm: commercially available, Xiaoli silica sol;

[0016] (2), glycine: commercially available, purity 99.99%;

[0017] (3), hydrogen peroxide: commercially available, mass fraction is 25%;

[0018] (4), fatty alcohol polyoxyethylene ether: commercially available, with a purity of 99.99%, produced by Tianjin Jingling Microelectronics Materials Co., Ltd.;

[0019] (5), chitosan: commercially available, purity 99.99%;

[0020] (6), potassium hydroxide: commercially available, purity 99.99%;

[0021] (7) Deionized water: self-made ultrapure water with a resistivity of 18MΩ*cm (25°C).

[0022...

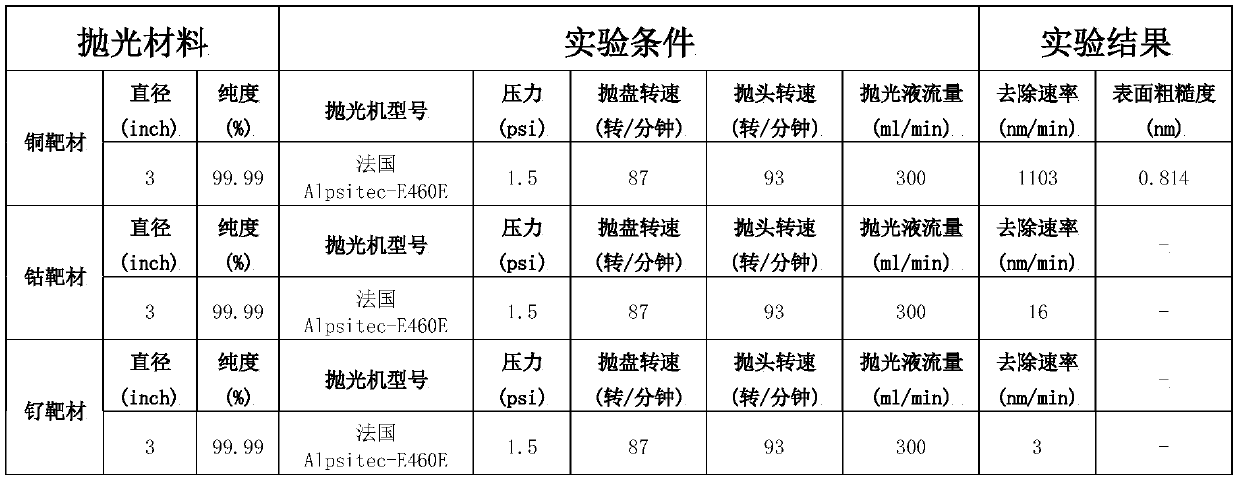

Embodiment 2

[0033] 1. Material ratio, based on the total weight of the mixture as 100, and the percentage of each material, SiO 2 20% silica sol with a particle size of 70-90nm 0.5 glycine 2 hydrogen peroxide 0.3 fatty alcohol polyoxyethylene ether 0.3 chitosan 0.03 potassium hydroxide 2 deionized water 94.87

[0034] 2. Material source

[0035] (1), SiO 2 20% silica sol with a particle size of 70-90nm: commercially available, Xiaoli silica sol;

[0036] (2), glycine: with embodiment 1;

[0037] (3), hydrogen peroxide: with embodiment 1;

[0038] (4), fatty alcohol polyoxyethylene ether: with embodiment 1;

[0039] (5), chitosan: with embodiment 1;

[0040] (6), potassium hydroxide: with embodiment 1;

[0041] (7), deionized water: with embodiment 1.

[0042] 3. A method for preparing a copper film alkaline polishing solution for low-tech node copper wiring, comprising the following steps in turn:

[0043] (1), weigh SiO according to the proportion 2 20% silica sol with a particl...

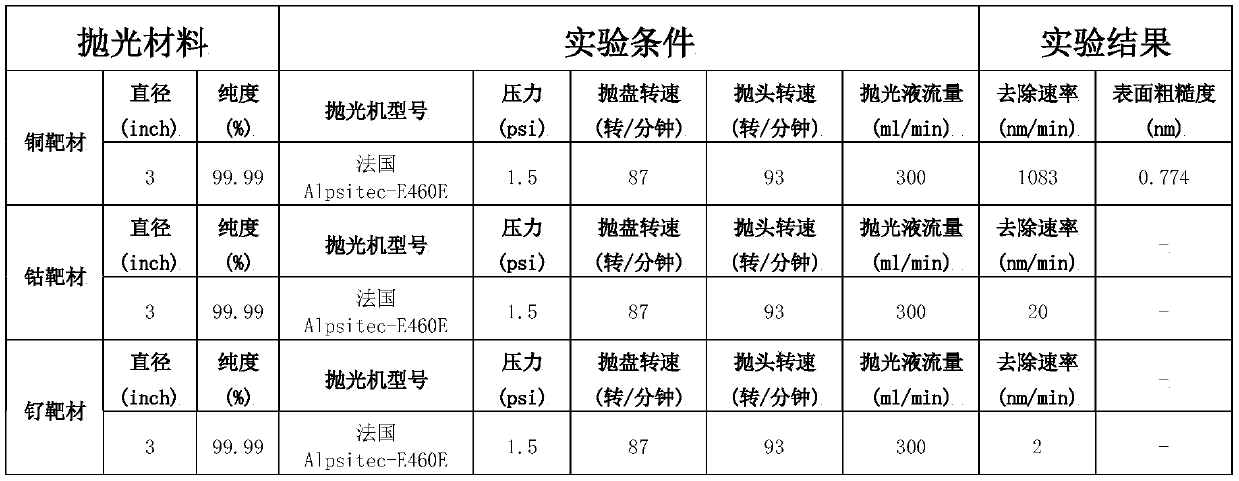

Embodiment 3

[0053] 1. Material ratio, based on the total weight of the mixture as 100, and the percentage of each material, SiO 2 30% silica sol with a particle size of 70-90nm 1 glycine 1 hydrogen peroxide 0.5 fatty alcohol polyoxyethylene ether 0.5 chitosan 0.05 potassium hydroxide 3 deionized water 93.95

[0054] 2. Material source

[0055] (1), SiO 2 30% silica sol with a particle size of 70-90nm: commercially available, Xiaoli silica sol;

[0056] (2), glycine: with embodiment 1;

[0057] (3), hydrogen peroxide: with embodiment 1;

[0058] (4), fatty alcohol polyoxyethylene ether: with embodiment 1;

[0059] (5), chitosan: with embodiment 1;

[0060] (6), potassium hydroxide: with embodiment 1;

[0061] (7), deionized water: with embodiment 1.

[0062] 3. A method for preparing a copper film alkaline polishing solution for copper wiring of low-tech nodes, comprising the following steps in turn:

[0063] (1), weigh SiO according to the proportion 2 30% silica sol with a particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com