Low-temperature jet flow plasma and monatomic catalysis coupled nitrogen fixation device and low-temperature jet flow plasma and monatomic catalysis coupled nitrogen fixation method

A jet plasma and plasma technology, which is applied to nitrogen fixation devices and fields of low temperature jet plasma coupled with single-atom catalysis, can solve the problems of poor selectivity, high comprehensive cost, low ammonia yield and the like, so as to improve the yield and reaction rate , The effect of strong adjustability and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

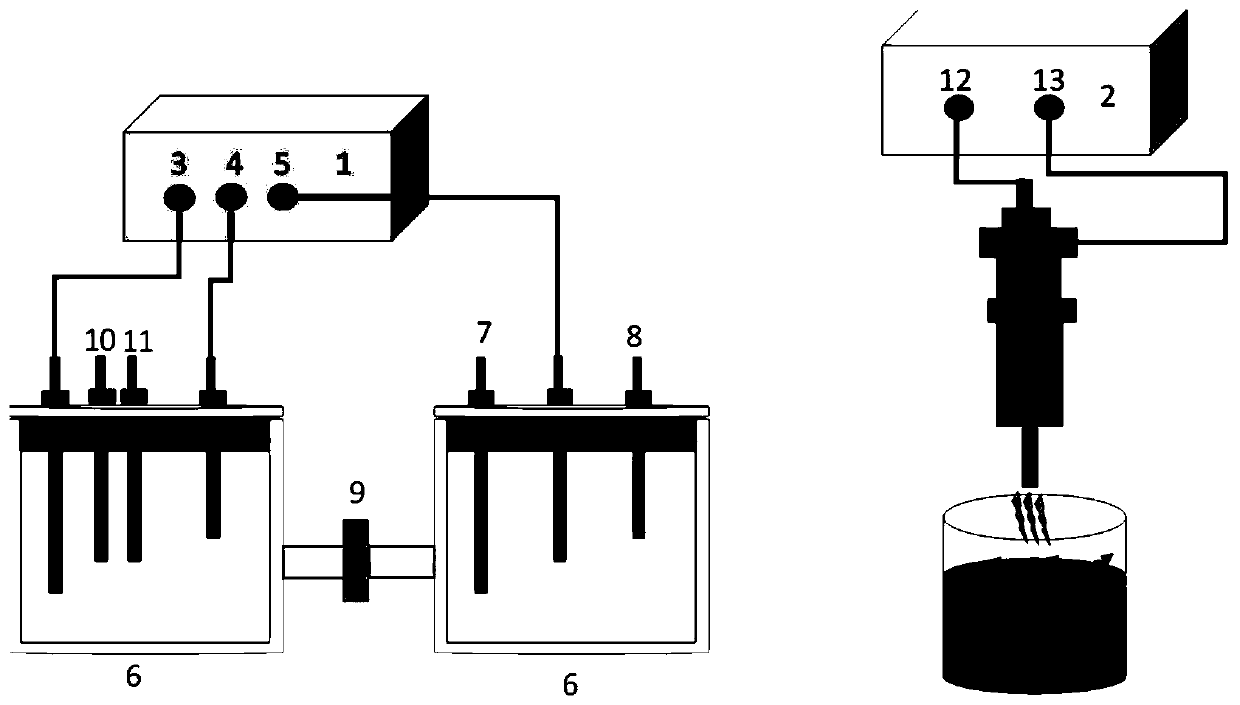

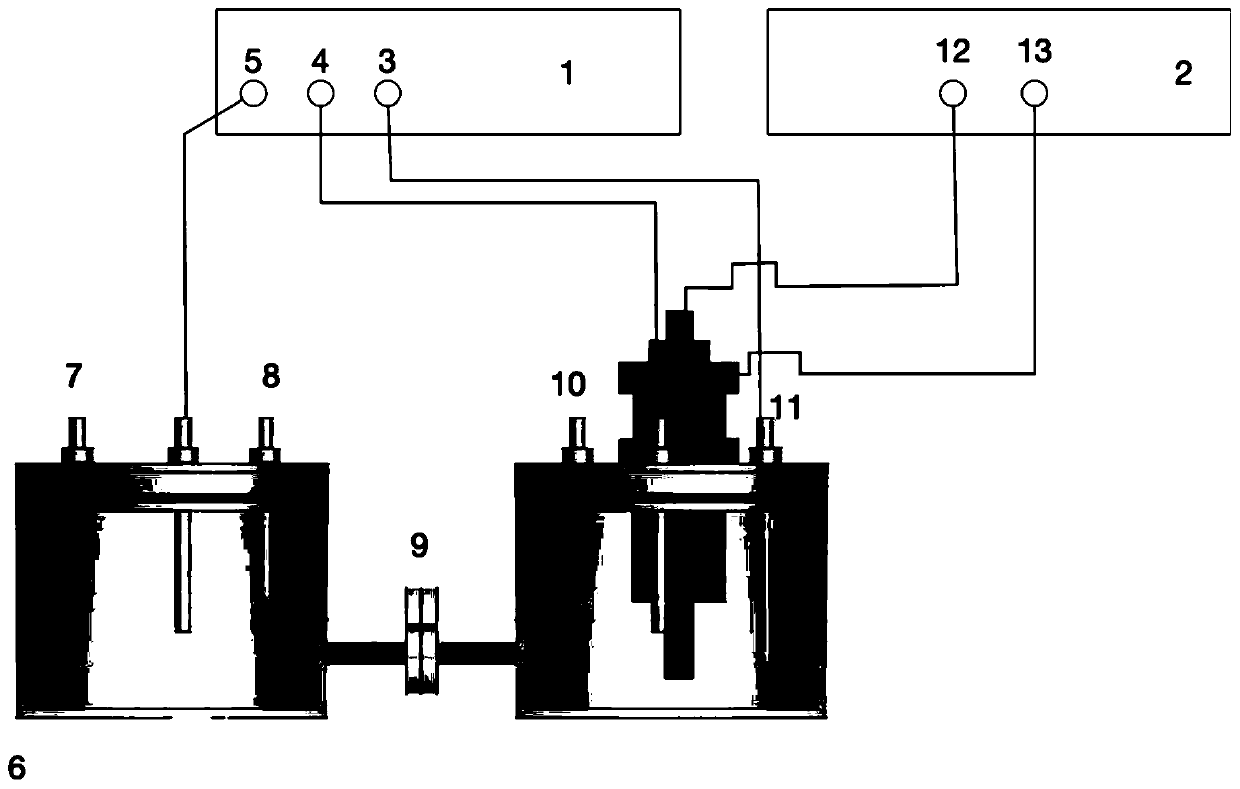

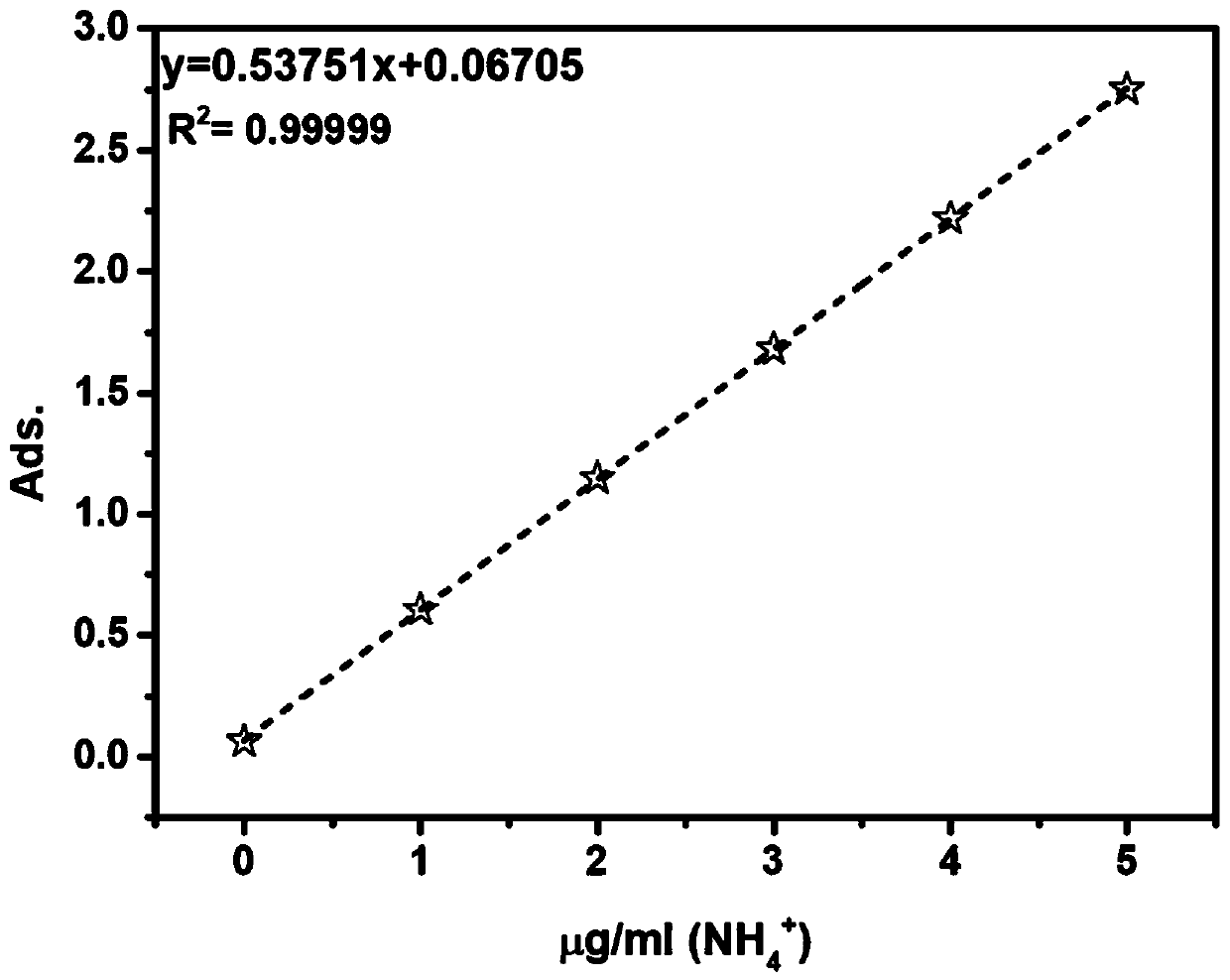

[0052] A tube furnace is used to calcine the precursor of the transition metal catalyst at a high temperature, the calcination temperature range is 800 degrees, and ammonia gas is passed into the tube furnace to prepare the Co single atom catalyst. The prepared load was 0.7 mg / cm 2 The Co single-atom catalyst, 0.7 μL of DuPont D520 (5% wt) nafion solution and 1 mL of absolute ethanol were dropped on carbon paper, and dried to prepare the working electrode of H-type electrolytic cell 6;

[0053] Get 160ml of 0.1M KOH in the reaction vessel, put the reaction vessel on the magnetic stirrer, set the rotating speed to 240rpm, adjust the distance between the discharge end of the jet plasma reactor 14 and the reaction liquid level in the reaction vessel to 1, 2, 3, 4, 5cm, connect the positive electrode 12 and the negative electrode 13 of the plasma power supply 2 to the jet plasma reactor 14, feed air into the jet plasma reactor 14 and adjust the flow rate to 7L / min through the mass...

Embodiment 6-10

[0059] A tube furnace is used to calcine the precursor of the transition metal catalyst at a high temperature, the calcination temperature range is 800 degrees, and ammonia gas is passed into the tube furnace to prepare the Co single atom catalyst. The prepared load was 0.7 mg / cm 2 The Co single-atom catalyst, 0.7 μL of DuPont D520 (5% wt) nafion solution and 1 mL of absolute ethanol were dropped on carbon paper, and dried to prepare the working electrode of H-type electrolytic cell 6;

[0060] Get 160ml of 0.1M KOH into the reaction vessel, place the reaction vessel on a magnetic stirrer, set the rotating speed to 240rpm, adjust the distance between the discharge end of the jet plasma reactor 14 and the reaction liquid level in the reaction vessel to 1cm, turn the plasma power supply 2 The positive electrode 12 of the power supply and the negative electrode 13 of the power supply are connected to the jet plasma reactor 14, the air is introduced into the jet plasma reactor 14 ...

Embodiment 11-15

[0066] A tube furnace is used to calcine the precursor of the transition metal catalyst at a high temperature, the calcination temperature range is 800 degrees, and ammonia gas is passed into the tube furnace to prepare the Co single atom catalyst. The prepared load was 0.7 mg / cm 2 The Co single-atom catalyst, 0.7 μL of DuPont D520 (5% wt) nafion solution and 1 mL of absolute ethanol were dropped on carbon paper, and dried to prepare the working electrode of H-type electrolytic cell 6;

[0067] Get 160ml of 0.1M KOH into the reaction vessel, place the reaction vessel on a magnetic stirrer, set the rotating speed to 240rpm, adjust the distance between the discharge end of the jet plasma reactor 14 and the reaction liquid level in the reaction vessel to 1cm, turn the plasma power supply 2 The positive electrode 12 of the power supply and the negative electrode 13 of the power supply are connected to the jet plasma reactor 14, and pure nitrogen, air, N 2 :O 2 =9:1, N 2 :O 2 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com