A kind of positive electrode material with core-shell structure, its preparation method and application in lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of unstable structure of lithium-ion battery positive electrode materials, achieve improved electrochemical performance, high electrical conductivity and mechanical strength, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

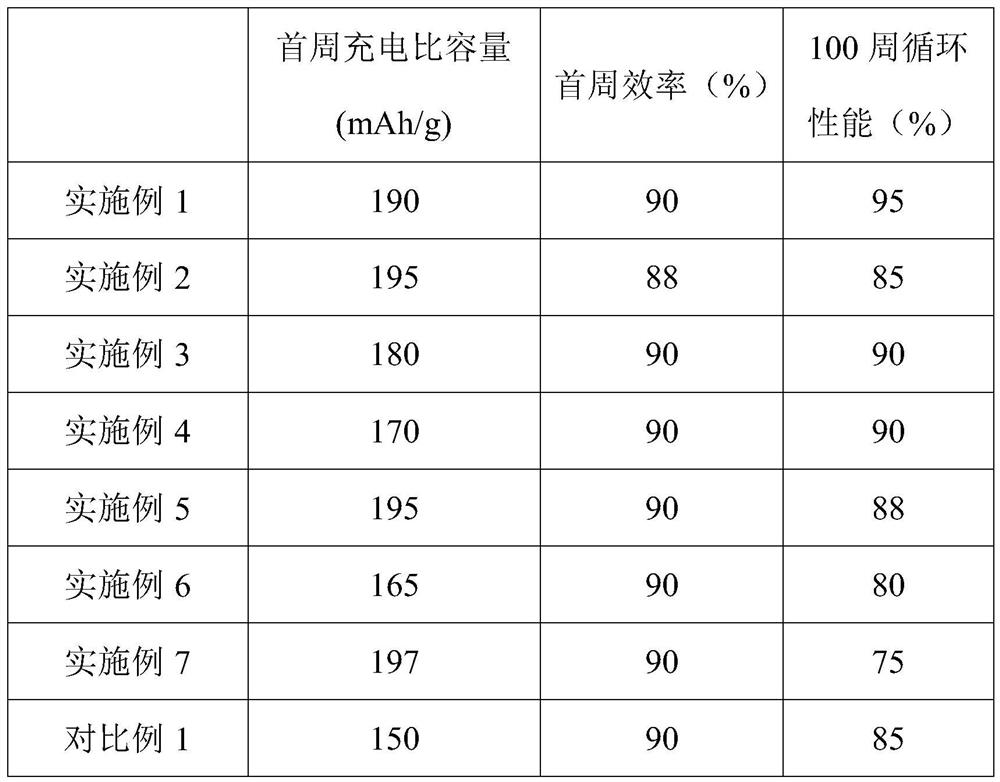

Examples

Embodiment 1

[0054] (1) Glucose, metal salt (nickel sulfate, cobalt sulfate and manganese sulfate molar ratio is 8:1:1) and water are mixed, and the mol ratio of described glucose and metal salt is 1:1.4, and the mol ratio of described glucose and water Mass ratio is 8:100, obtains mixed material;

[0055] (2) Mix the mixed material, polyvinylpyrrolidone and ammonia water, the mass ratio of the mixed material and polyvinylpyrrolidone is 10:1, the pH value of the material obtained after mixing is 11, and the hydrothermal reaction is carried out, and the temperature is changed by The room temperature was raised to 80°C and kept for 10 hours, then raised to 180°C and kept for 10 hours to obtain the reaction precursor;

[0056] (3) Mix the reaction precursor with lithium hydroxide, the molar ratio of the reaction precursor to lithium hydroxide is 1:1.05, the atmosphere is argon, and the temperature is 900 ° C for 12 hours to sinter to obtain a diameter of 300 nm, A core-shell positive electro...

Embodiment 2

[0058] (1) Glucose, metal salt (nickel sulfate, cobalt sulfate and manganese sulfate molar ratio is 8:1:1) and water are mixed, and the mol ratio of described glucose and metal salt is 1:2, and the mol ratio of described glucose and water Mass ratio is 5:100, obtains mixed material;

[0059] (2) mixing the mixed material, citric acid and ammonia water, the mass ratio of the mixed material and citric acid is 12:1, the pH value of the material obtained after mixing is 10.5 (adjusted by ammonia water), and the hydrothermal reaction is carried out, Raise the temperature from room temperature to 100°C, keep it warm for 5 hours, then raise it to 240°C, keep it warm for 4 hours, and obtain the reaction precursor;

[0060] (3) Mix the reaction precursor with lithium hydroxide, the molar ratio of the reaction precursor to lithium hydroxide is 1:1.08, the atmosphere is argon, and the temperature is 850 ° C for 14 hours to sinter to obtain a diameter of 350 nm, A core-shell positive ele...

Embodiment 3

[0062] (1) Glucose, metal salt (nickel sulfate, cobalt sulfate and manganese sulfate molar ratio is 8:1:1) and water are mixed, and the mol ratio of described glucose and metal salt is 1:1, and the mol ratio of described glucose and water Mass ratio is 10:100, obtains mixed material;

[0063] (2) the mixed material, sodium lauryl sulfate and ammoniacal liquor are mixed, and the mass ratio of described mixed material and sodium lauryl sulfate is 8:1, and the material pH value that obtains after mixing is 11.5 (using ammoniacal liquor Adjustment), carry out hydrothermal reaction, raise the temperature from room temperature to 60°C, keep it for 18h, then raise it to 160°C, keep it for 8h, and get the reaction precursor;

[0064] (3) Mix the reaction precursor with lithium hydroxide, the molar ratio of the reaction precursor to lithium hydroxide is 1:1.1, the atmosphere is argon, and the temperature is 950 ° C for 10 hours to obtain a diameter of 400nm. A core-shell positive elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com