Preparation method of photoelectrocatalysis anode material taking TNTs as substrate

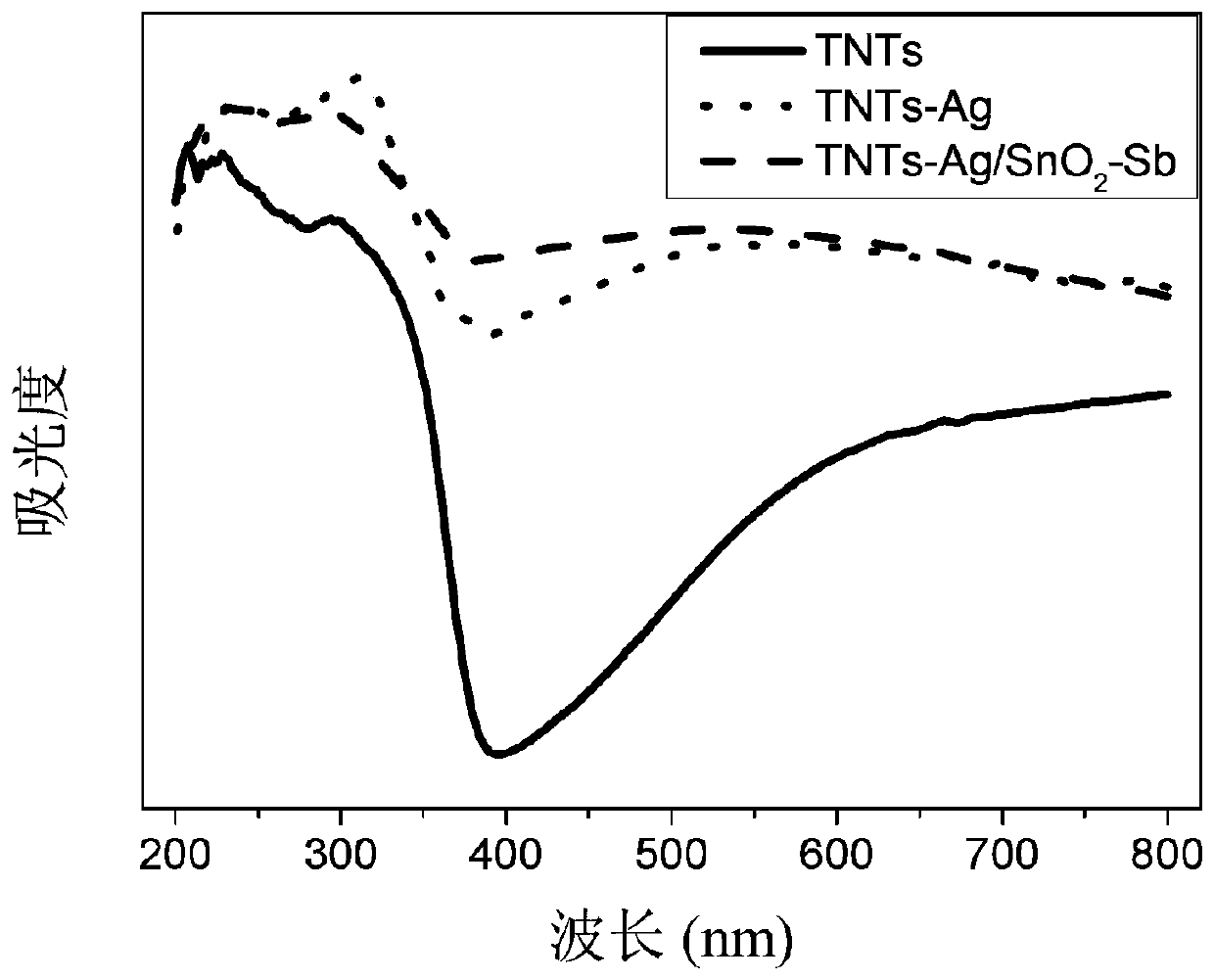

A kind of anode material, photoelectric catalysis technology, applied in the direction of chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., can solve the problem of low utilization rate of light energy and electric energy, achieve the improvement of photocatalytic activity, instruments and equipment Low-demand, high-reproducibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method taking TNTs as substrate photoelectric catalysis anode material, specifically comprises the following steps:

[0034] (1) Choose a titanium plate of 30×30×0.3mm, soak the titanium plate in NaOH solution for 1 hour, then corrode it in oxalic acid and nitric acid solution for 0.5h and 6h respectively and heat it to 90°C, and finally use ultra-pure Rinse with water and dry, then put it into a mixed solution of acetone and ethanol and sonicate for 30 minutes, rinse with ultrapure water, dry, and set aside.

[0035](2) Put the pretreated titanium plate into 100ml of ethylene glycol system electrolyte with ammonium fluoride and water as the electrolyte (the concentration of ammonium fluoride is 0.1mol / L, and the volume of water is 1% of the volume of ethylene glycol. %), with Pt as the cathode, the treated titanium plate as the anode, and a constant voltage of 50V to carry out anodic oxidation on the pretreated titanium plate for 3 hours; after wa...

Embodiment 2

[0052] A kind of preparation method taking TNTs as substrate photoelectric catalysis anode material, specifically comprises the following steps:

[0053] (1) Choose a titanium plate of 30×30×0.3mm, soak the titanium plate in NaOH solution for 1 hour, then corrode it in oxalic acid and nitric acid solution for 0.5h and 6h respectively and heat it to 90°C, and finally use ultra-pure Rinse with water and dry, then put it into a mixed solution of acetone and ethanol and sonicate for 30 minutes, rinse with ultrapure water, dry, and set aside.

[0054] (2) Put the pretreated titanium plate into 100ml of ethylene glycol system electrolyte with ammonium fluoride and water as the electrolyte (the concentration of ammonium fluoride is 0.2mol / L, and the volume of water is 2 times the volume of ethylene glycol. %), with Pt as the cathode, the treated titanium plate as the anode, and a constant voltage of 40V was used to anodize the pretreated titanium plate for 3 hours; after washing with...

Embodiment 3

[0059] A kind of preparation method taking TNTs as substrate photoelectric catalysis anode material, specifically comprises the following steps:

[0060] (1) Choose a titanium plate of 30×30×0.3mm, soak the titanium plate in NaOH solution for 1 hour, then corrode it in oxalic acid and nitric acid solution for 0.5h and 6h respectively and heat it to 90°C, and finally use ultra-pure Rinse with water and dry, then put it into a mixed solution of acetone and ethanol and sonicate for 30 minutes, rinse with ultrapure water, dry, and set aside.

[0061] (2) Put the pretreated titanium plate into 100ml ethylene glycol system electrolyte with ammonium fluoride and water as the electrolyte (the concentration of ammonium fluoride is 0.15mol / L, and the volume of water is 1.5 mol / L of the volume of ethylene glycol. %), with Pt as the cathode, the treated titanium plate as the anode, and a constant voltage of 60V to carry out anodic oxidation on the pretreated titanium plate for 3 hours; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com