Copper nitride thin-film solar cell and preparation method thereof

A technology of solar cells and copper nitride, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of reducing lattice heat loss, improving efficiency, and broadening the spectral range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

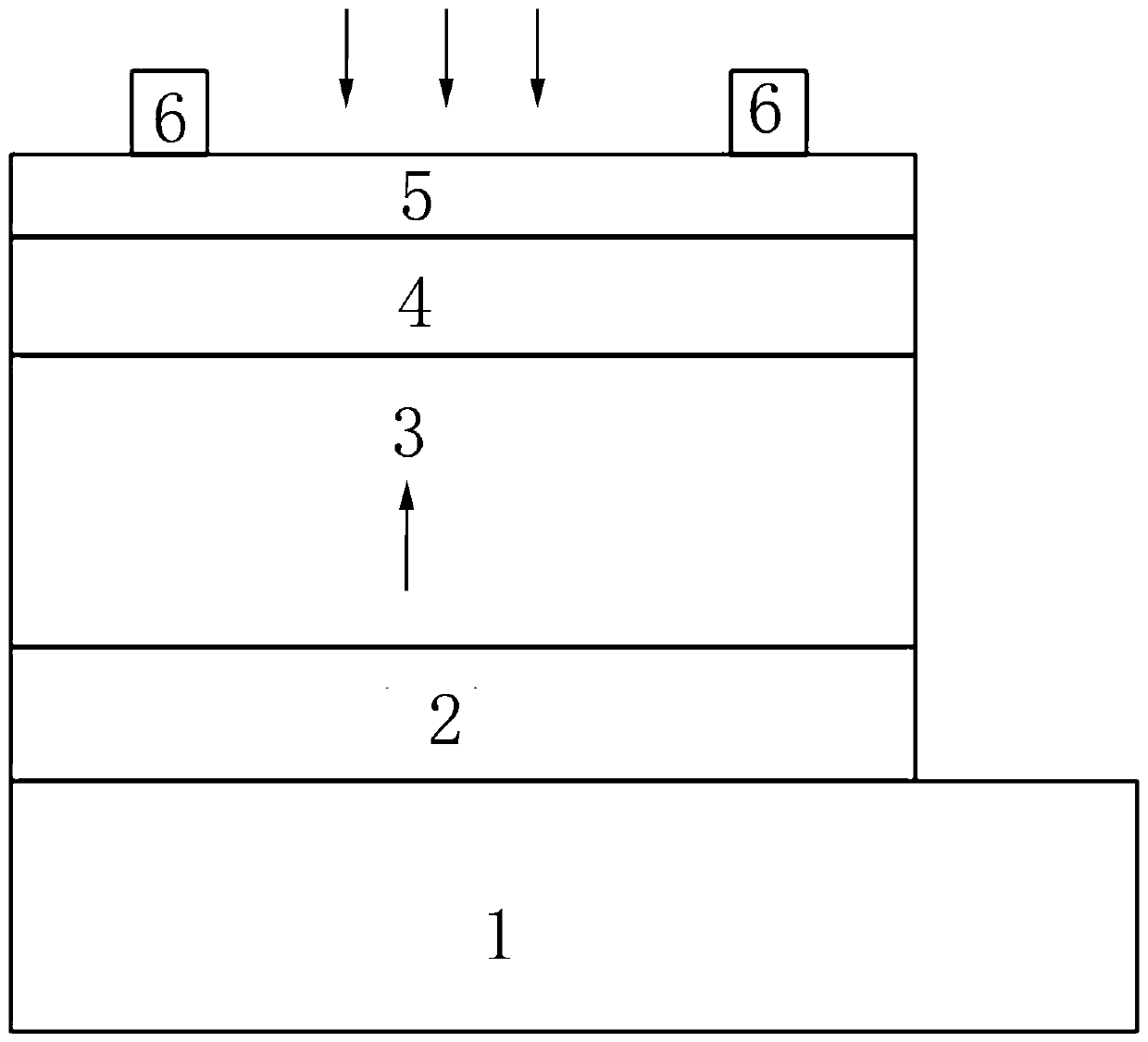

[0019] The copper nitride thin film solar cell of this embodiment includes the following structure from bottom to top: ITO glass 1, magnesium doped copper nitride thin film 2, composition graded copper nitride thin film 3, selenium doped copper nitride thin film 4, In the ITO film 5 and the silver electrode 6, in the composition-graded copper nitride film 3, the content of nitrogen gradually increases from bottom to top. The composition graded copper nitride film 3 has a thickness of 500nm and is divided into 10 layers, each layer is 50nm, and the nitrogen content gradually increases from bottom to top. Sunlight is irradiated from above the silver electrode 6 .

[0020] When preparing:

[0021] 1) Main raw materials and equipment

[0022] Copper, selenium, magnesium, ITO (indium tin oxide) and other targets: purity 99.99%, diameter 60mm, thickness 5mm.

[0023] ITO conductive glass: area ~ 25×25mm 2 , Sheet resistance ~ 15Ω / □, light transmittance ≥ 90%.

[0024] Nitrogen,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com