Preparation method and applications of antibacterial and biodegradable zinc alloy anastomosis nail

A zinc alloy and staple technology, applied in the directions of staples, staples, mechanical equipment, etc., can solve the problems of difficult processing of degradable magnesium alloy staples, unsuitable degradable zinc alloys, non-degradable staples, etc. Good deformability, low processing cost and suitable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

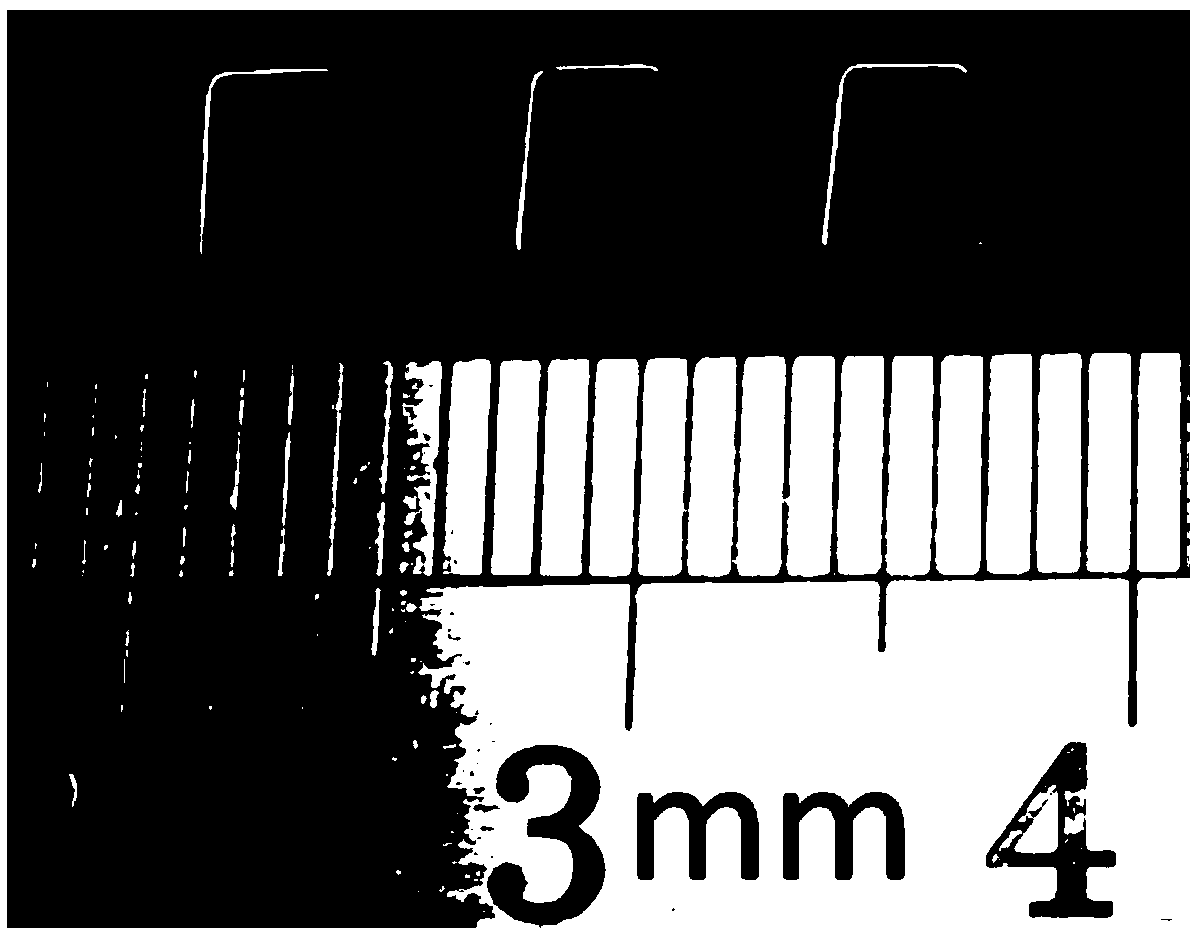

Embodiment 1

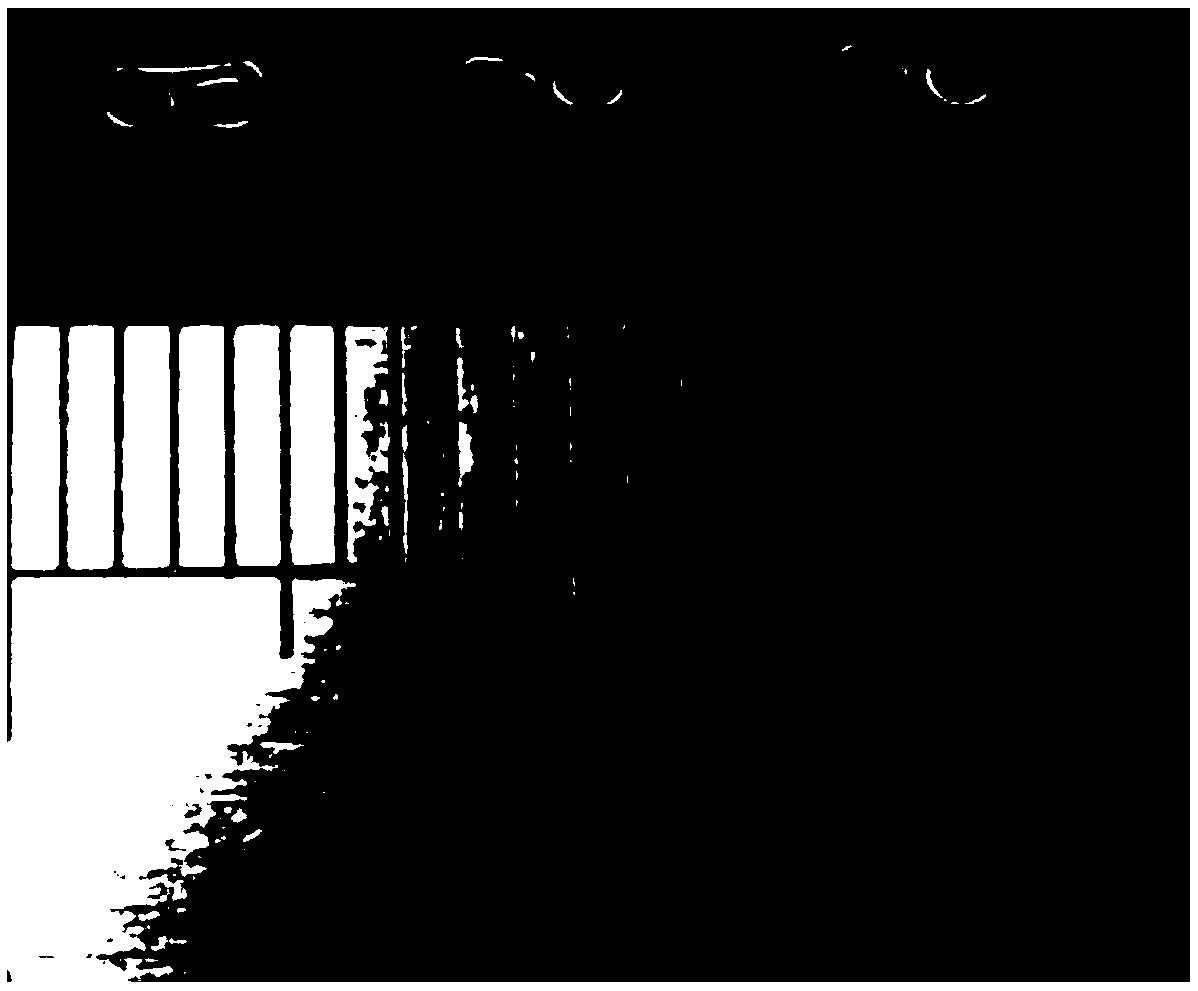

[0030] A Zn-3wt%Cu alloy was machined into cylindrical billets for extruded wire. Graphite oil is coated on the surface of the die and the extruded wire blank as a lubricant before extrusion. The billets were extruded into filaments (1.5 mm in diameter) at a temperature of 180°C. The tensile strength of the filament is 240MPa, the yield strength is 200MPa, the elongation is 50%, and the corrosion rate in simulated body fluid is 0.04mm / year. The antibacterial rate for Escherichia coli and Staphylococcus aureus reaches 90%. The filaments were drawn for multiple passes to obtain filaments with a diameter of 0.2 mm. Carry out machining to above-mentioned wire material and obtain staple (such as figure 1 ), implanted into the stapler cartridge, sterilized and packaged to obtain the final product.

[0031] Prepare the wire into a B-shaped staple (such as figure 2), and then tie the two ends of the B-shaped staples with thin wires, one end of which is fixed on the tension gauge...

Embodiment 2

[0033] A Zn-3wt%Cu-1wt%Mn alloy was machined into a cylindrical billet for extruded wire. Graphite oil is coated on the surface of the die and the extruded wire blank as a lubricant before extrusion. The billets were extruded into filaments (1.5 mm in diameter) at a temperature of 180°C. The tensile strength of the filament is 350MPa, the yield strength is 240MPa, the elongation is 30%, and the corrosion rate in simulated body fluid is 0.06mm / year. The antibacterial rate for Escherichia coli and Staphylococcus aureus reaches 92%. The filaments were drawn for multiple passes to obtain filaments with a diameter of 0.3 mm. The above-mentioned wire is machined to obtain a staple, which is coated and implanted into a stapler cartridge, sterilized and packaged to obtain a final product.

[0034] Prepare the wire material into a B-shaped staple, and then fasten the two ends of the B-shaped staple with thin wires, one end of which is fixed on the tension gauge, and then pull the ot...

Embodiment 3

[0036] A Zn-5wt%Ag alloy was machined into cylindrical billets for extruded wire. Graphite oil is coated on the surface of the die and the extruded wire blank as a lubricant before extrusion. The billets were extruded into filaments (1.5 mm in diameter) at a temperature of 180°C. The tensile strength of the filament is 270MPa, the yield strength is 210MPa, the elongation is 45%, and the corrosion rate in simulated body fluid is 0.05mm / year. The antibacterial rate for Escherichia coli and Staphylococcus aureus reaches 95%. A filament with a diameter of 0.4 mm was obtained after drawing the filament for multiple passes. The above wire is machined to obtain staples, which are coated and drug-loaded, implanted into stapler cartridges, sterilized and packaged to obtain final products.

[0037] Prepare the wire material into a B-shaped staple, and then fasten the two ends of the B-shaped staple with thin wires, one end of which is fixed on the tension gauge, and then pull the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com