Bone repair and tumor suppression material with photothermal conversion performance and functional coating and preparation method

A photothermal conversion material and photothermal conversion technology, applied in coatings, pharmaceutical formulations, prostheses, etc., can solve the problems of life-threatening, single function, easy transfer of bone tumors, etc., to promote osseointegration, simple operation steps, The effect of inhibiting the growth of tumor cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The processing steps of the present embodiment are as follows:

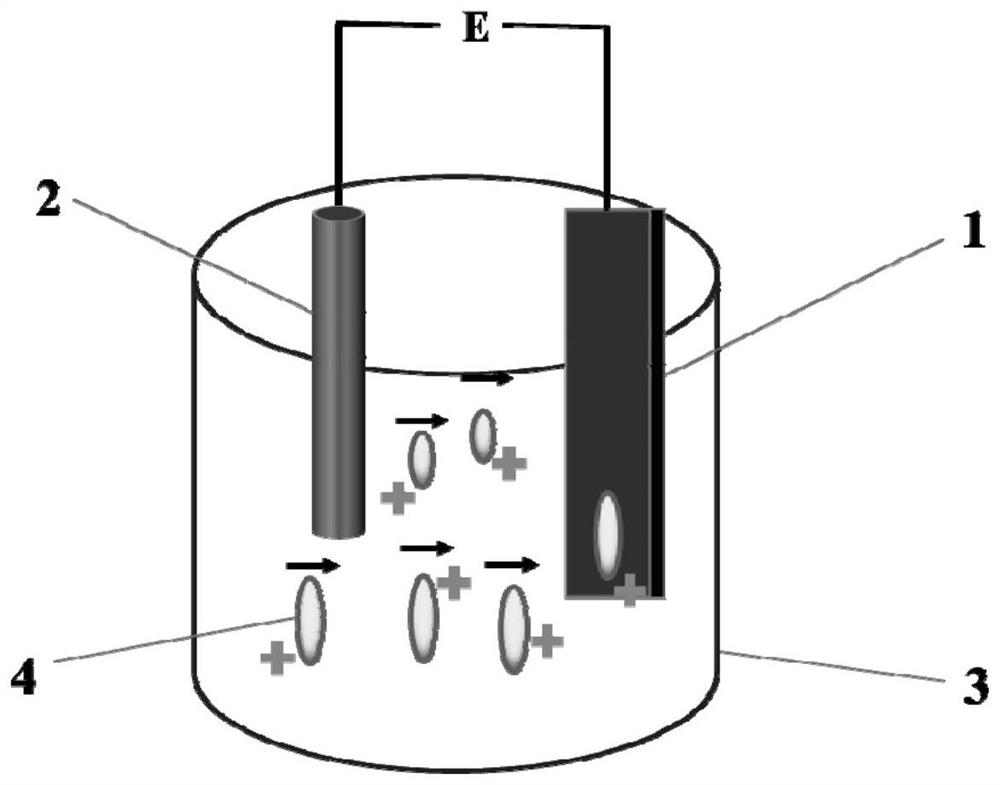

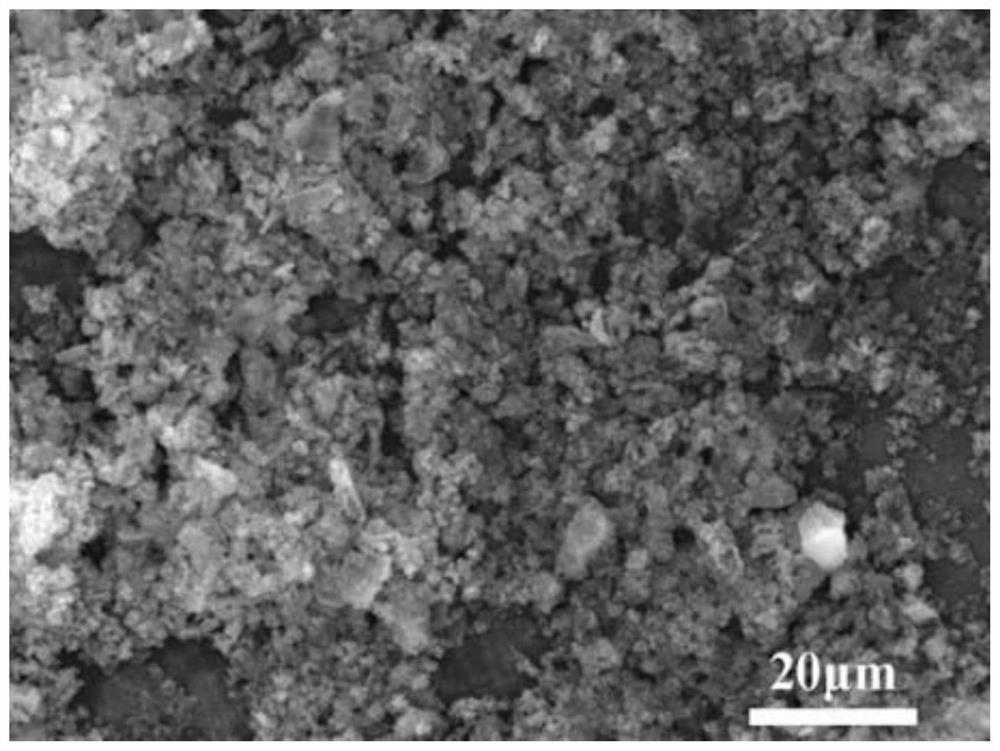

[0037] (1) Preparation of substrates with electrical conductivity and light-to-heat conversion properties

[0038] Weigh 24.0g of polyetheretherketone powder and place it in a beaker, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain a polyetheretherketone dispersion; weigh 6.0g of nanoscale graphene, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain a graphene dispersion , the number of nano-sheets of the nano-scale graphene is 1-5 layers, and the average radial size is 200 μm; the polyetheretherketone dispersion and the graphene dispersion are mixed together, ultrasonically dispersed for 30 minutes, filtered and dried Obtain uniformly mixed polyether ether ketone and graphene mixed powder; the polyether ether ketone and graphene mixed powder is molded into a circular truncated shape by injection molding, and the processing temperature is 370 ° C. Af...

Embodiment 2

[0050] The processing steps of the present embodiment are as follows:

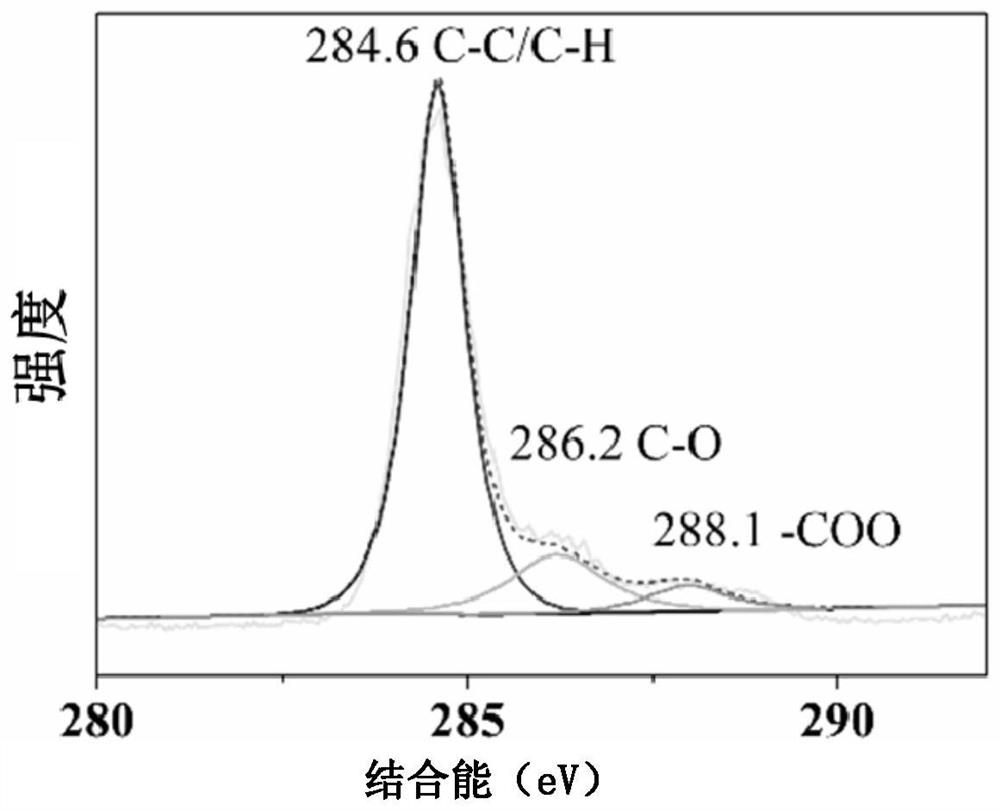

[0051] (1) Preparation of substrates with electrical conductivity and light-to-heat conversion properties

[0052] Weigh 24.0g of polyetheretherketone powder and place it in a beaker, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain a polyetheretherketone dispersion; weigh 6.0g of nanoscale graphene oxide, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain graphene oxide Dispersion liquid, the number of nano-sheets of nano-scale graphene oxide is 1 to 5 layers, and the average radial size is 200 μm; the polyetheretherketone dispersion liquid and graphene oxide dispersion liquid are mixed together, ultrasonically dispersed for 30 minutes, and pumped Filtration and drying to obtain uniformly mixed polyetheretherketone and graphene oxide mixed powder; the polyether ether ketone and graphene oxide mixed powder is molded into a circular truncated shape by ...

Embodiment 3

[0062] The processing steps of the present embodiment are as follows:

[0063] (1) Preparation of substrates with electrical conductivity and light-to-heat conversion properties

[0064] Weigh 19.98g of polyetheretherketone powder and place it in a beaker, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain a polyether ether ketone dispersion; weigh 0.02g of nano-scale black phosphorus, add 100ml of ethanol, and disperse it ultrasonically for 30 minutes to obtain a black phosphorus dispersion ; Mix the polyether ether ketone dispersion and black phosphorus dispersion together, ultrasonically disperse for 30 minutes, and obtain a uniformly mixed polyether ether ketone and black phosphorus mixed powder through suction filtration and drying; mix polyether ether ketone and black phosphorus The mixed powder is formed into a circular truncated shape by 3D printing, and its processing temperature is 370 ° C. After cooling, a matrix with electrical conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com