High-performance carbon positive electrode PAN hard carbon material and preparation method thereof

A carbon anode, high-performance technology, applied in the preparation/purification of carbon, battery electrodes, electrical components, etc., can solve the problems of poor rate performance of layered graphite anodes, increased lithium ion diffusion resistance, small interlayer spacing, etc., to achieve Easy industrial production, low production cost, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In step 1, the porcelain boat is covered with polyacrylonitrile powder, and the relative molecular weight of polyacrylonitrile powder is 15W.

[0029] Step 2, pre-oxidation: put the porcelain boat into a tube furnace for pre-oxidation. That is, the polyacrylonitrile was raised from room temperature to 280 °C at a rate of 1 °C / min in an oxygen atmosphere, kept for 2 hours, and cooled to room temperature.

[0030] Step 3, carbonization: raise the pre-oxidized polyacrylonitrile obtained in step 2 from room temperature to 600°C at 1°C / min in an argon atmosphere, keep it warm for 0.5h, then raise the temperature to 1100°C at 3°C / min and keep it warm for 1h . Cool to room temperature. The high-performance carbon anode PAN hard carbon material prepared by the present invention is obtained.

[0031] Step 4, cleaning impurities: grind the block in step 3, pass through a 100-mesh sieve, and ultrasonically disperse the obtained powder in alcohol or dimethylformamide at 60°C for...

Embodiment 2

[0033] Step 1: Cover the porcelain boat with polyacrylonitrile powder.

[0034] Step 2, pre-oxidation: put the porcelain boat into a tube furnace for pre-oxidation. Then, the polyacrylonitrile was raised from room temperature to 250° C. at a rate of 5° C. / min in an oxygen atmosphere, kept for 2 hours, and cooled to room temperature.

[0035] Step 3, carbonization: raise the pre-oxidized polyacrylonitrile obtained in step 2 from room temperature to 500°C at 3°C / min in an argon atmosphere, keep it warm for 0.5h, then raise the temperature to 1050°C at 4°C / min and keep it warm for 1h . Cool to room temperature. The high-performance carbon anode PAN hard carbon material prepared by the present invention is obtained.

[0036] Step 4, cleaning impurities: grind the block in step 3, pass through a 200-mesh sieve, and ultrasonically disperse the obtained powder in methanol at 60°C for 2 hours, filter with suction, dry to obtain pure hard polyacrylonitrile powder, and grind again 3...

Embodiment 3

[0038] Step 1: Cover the porcelain boat with polyacrylonitrile powder.

[0039] Step 2, put the porcelain boat into the tube furnace for pre-oxidation treatment. Then, the polyacrylonitrile was raised from room temperature to 300° C. at a rate of 3° C. / min in an oxygen atmosphere, kept for 2 hours, and cooled to room temperature.

[0040] Step 3, carbonization: raise the pre-oxidized polyacrylonitrile obtained in step 2 from room temperature to 550°C at 2°C / min in an argon atmosphere, keep it warm for 0.5h, then raise the temperature to 1000°C at 6°C / min and keep it warm for 1h . Cool to room temperature. The high-performance carbon anode PAN hard carbon material prepared by the present invention is obtained.

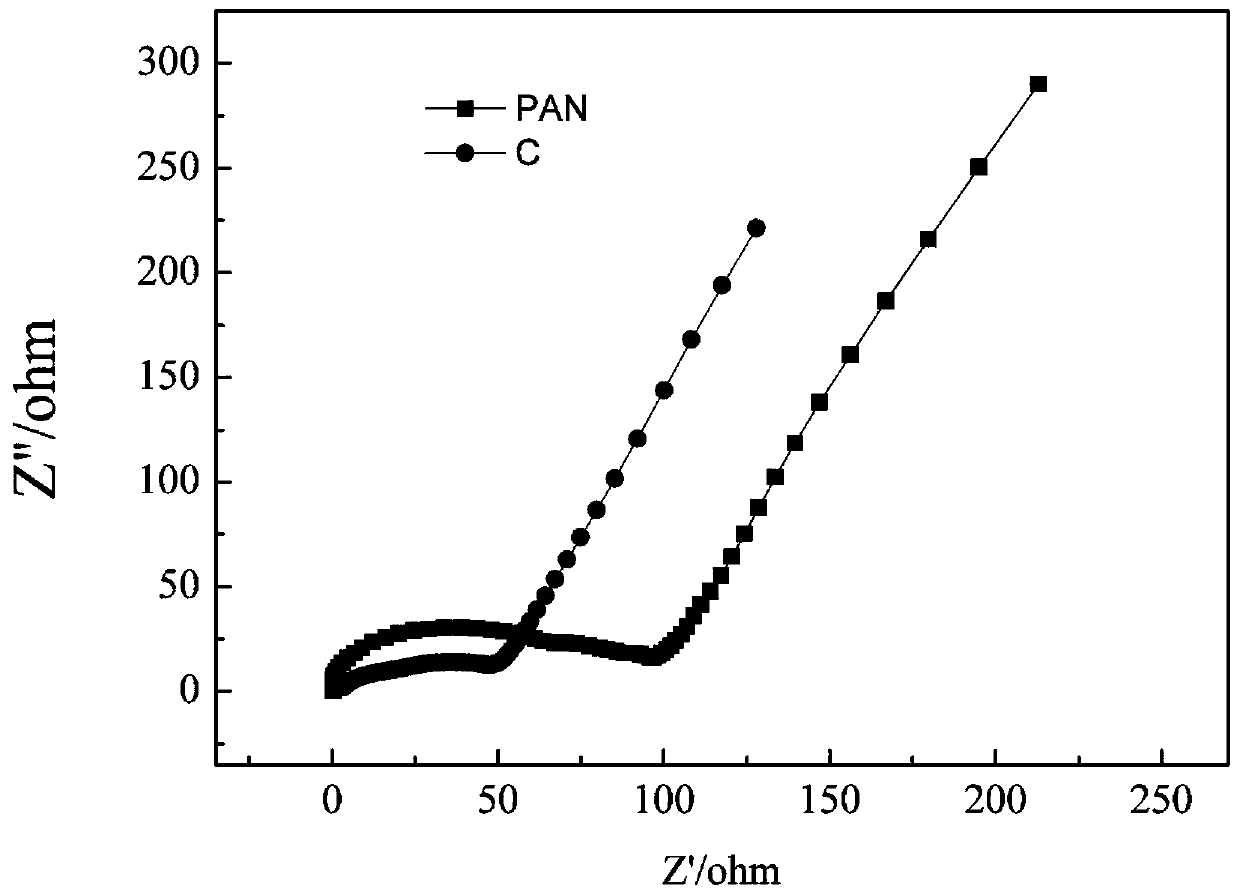

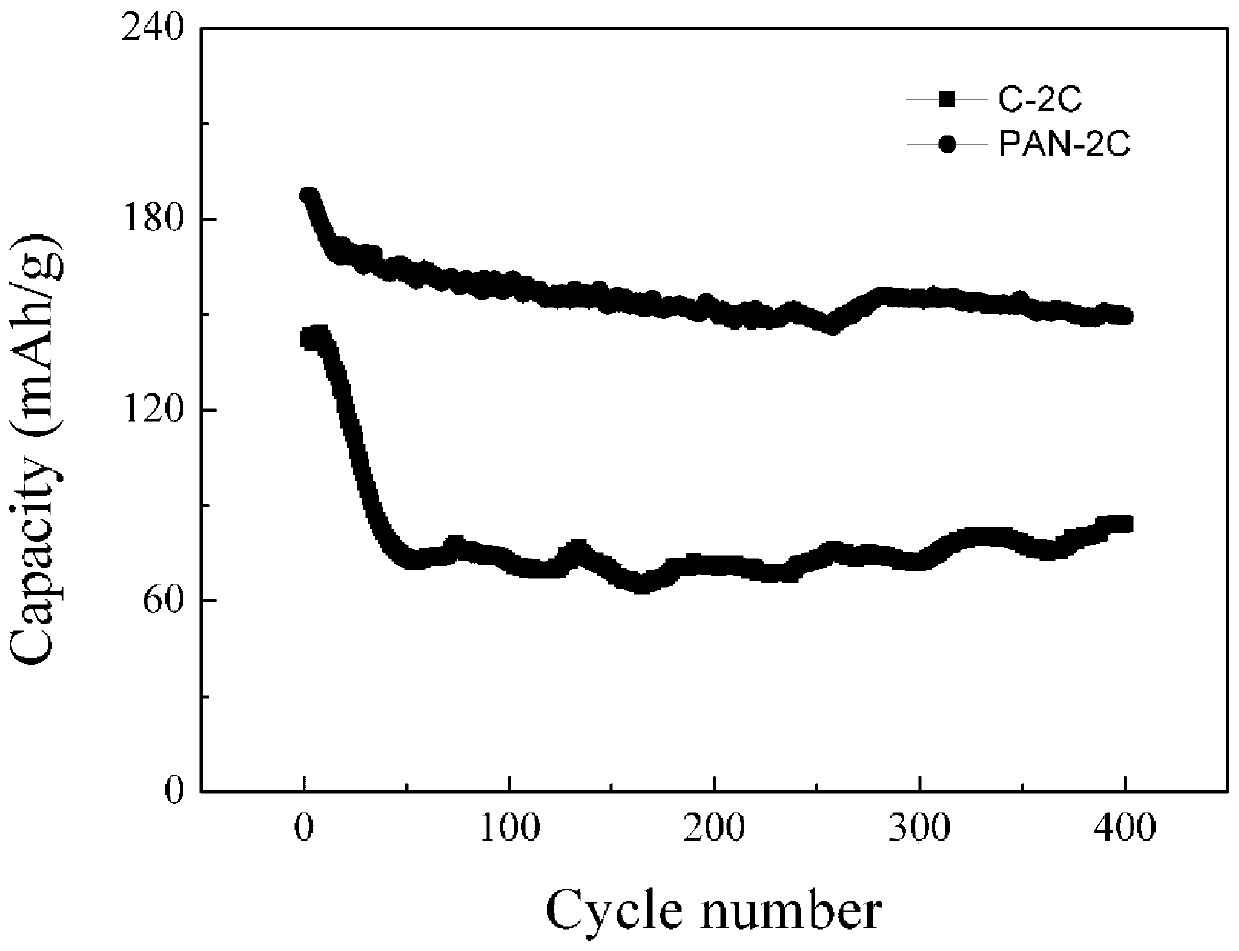

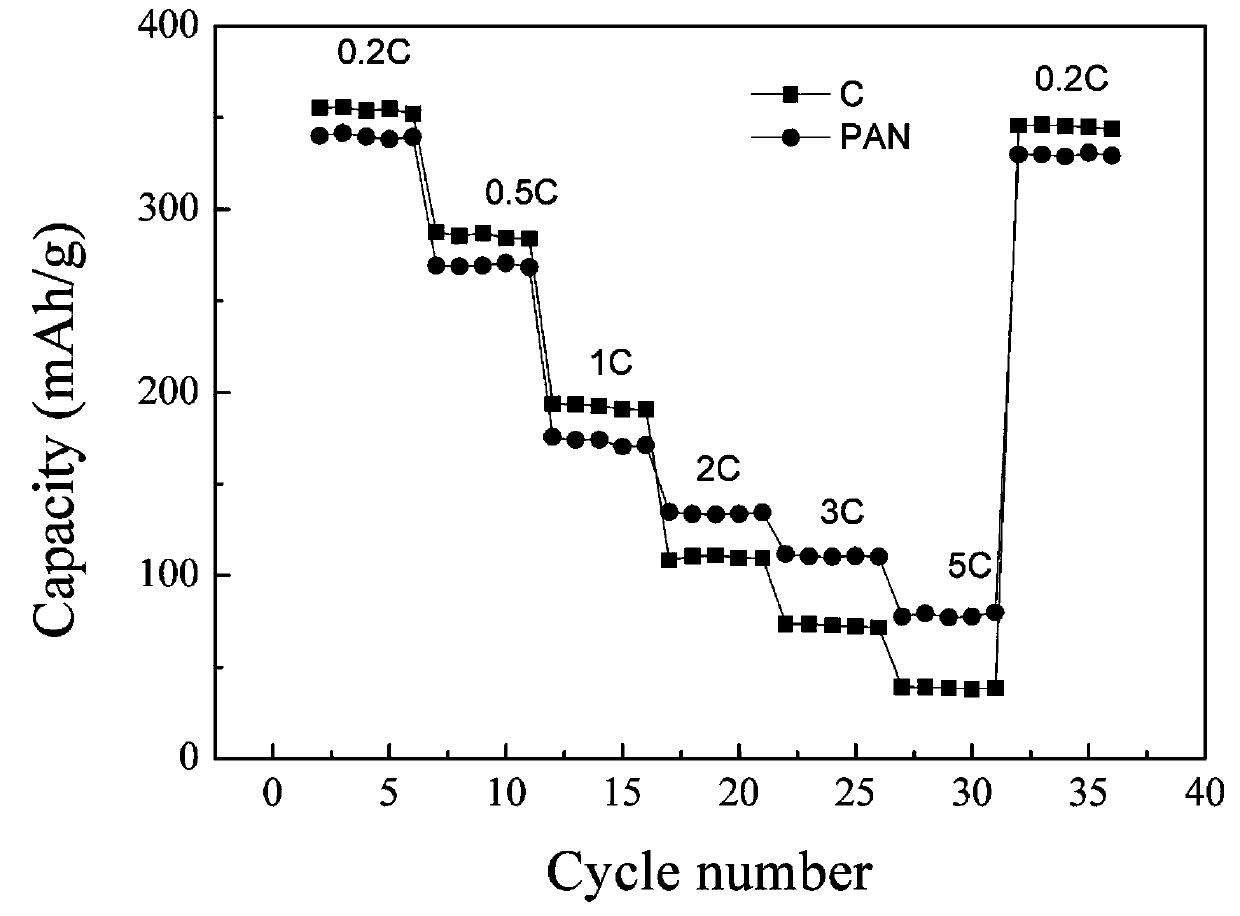

[0041] Such as figure 1 Shown, the impedance figure of the negative electrode material of lithium ion battery prepared by the present invention has shown the EIS spectrum of PAN hard carbon and graphite electrode, and in the high-frequency region, the semicircular a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com