A-type zeolite molecular sieve and preparation method and application thereof

A zeolite molecular sieve and powder technology, which is applied in the field of A-type zeolite molecular sieve and its preparation, can solve the problems of unerased waste catalysts, such as climate, environment, and negative economic impact, and achieve the effects of reducing production costs and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

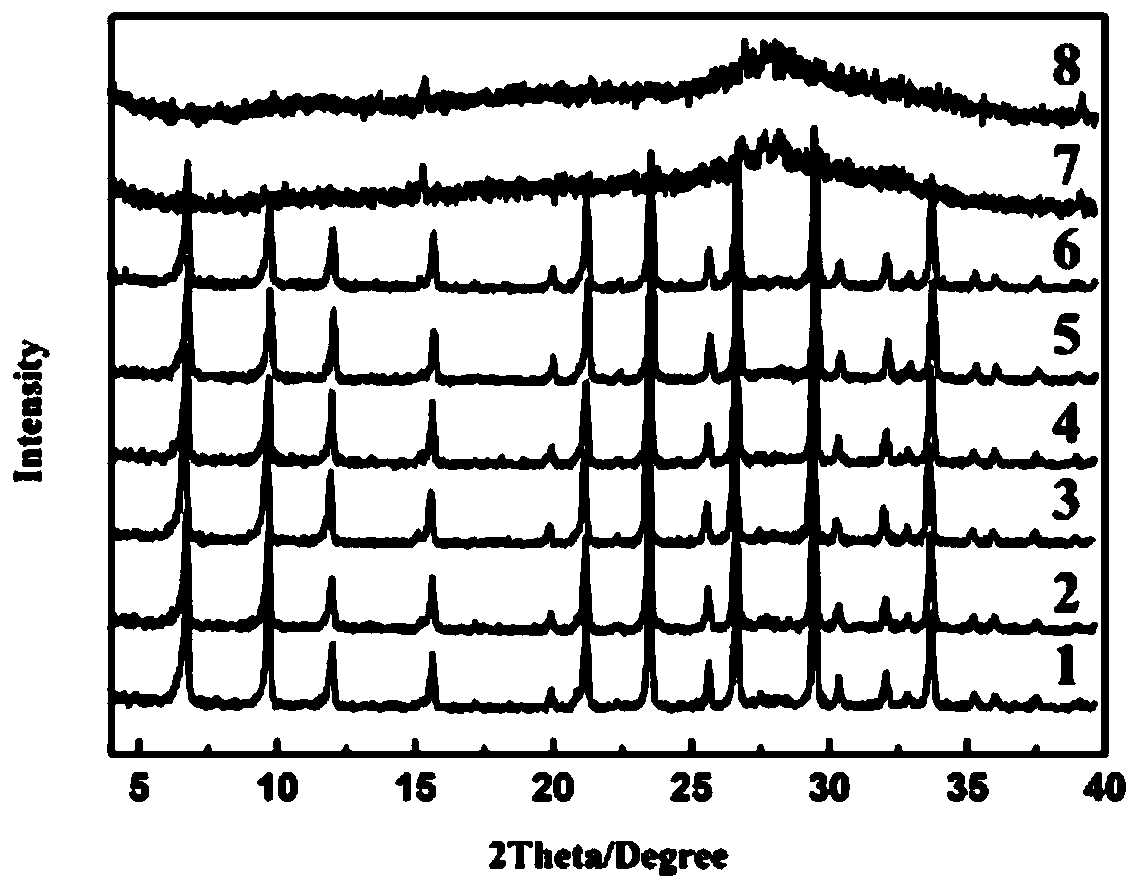

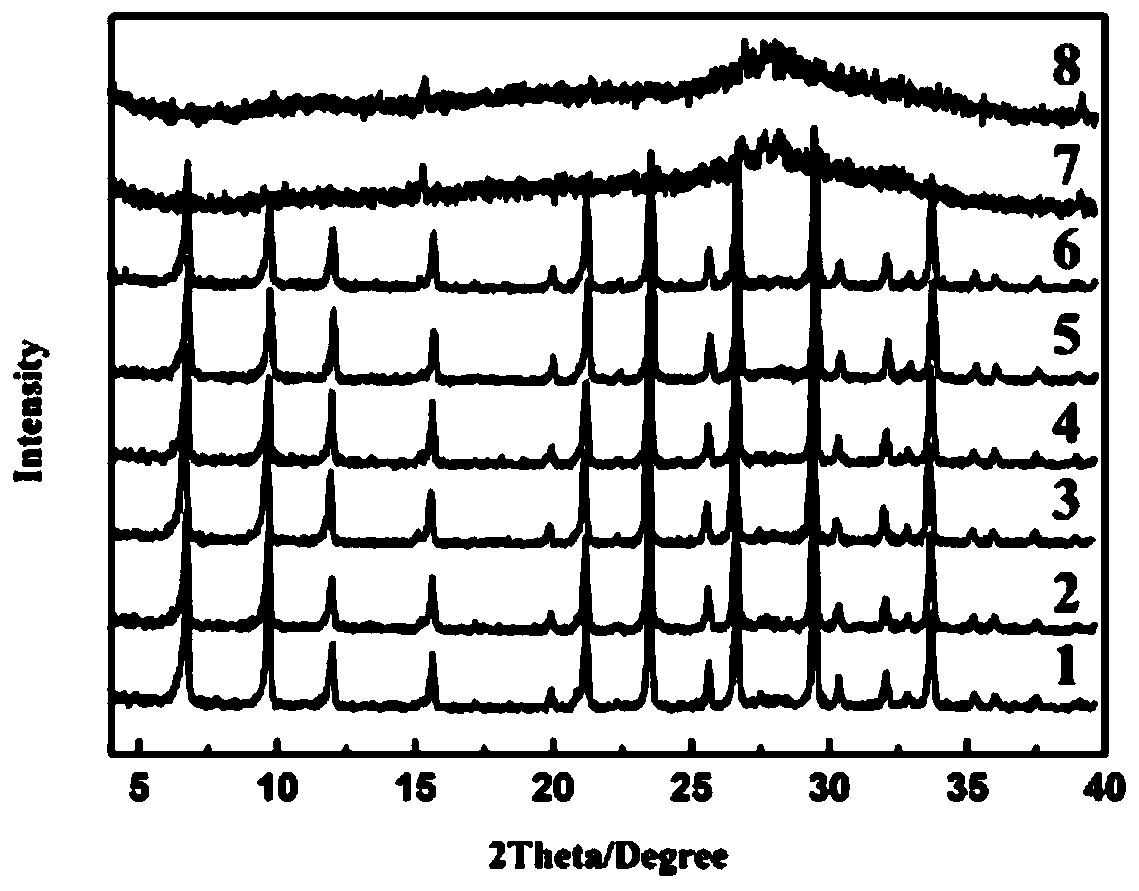

Image

Examples

preparation example Construction

[0020] The present invention relates to a kind of preparation method of A-type zeolite molecular sieve, comprising the following steps:

[0021] (1) First mix the cracking catalytic waste catalyst with sodium hydroxide and grind to obtain powder, then put the powder into a closed container and heat it to 160°C-210°C to activate the reaction for 1h-4h and then cool it down; wherein, the spent catalyst The parts by weight of the sodium hydroxide are 0.7-0.8 parts, and the parts by weight of the sodium hydroxide are 1-2 parts.

[0022] (2) Pour the powder obtained in the step (1) into a crystallization reaction vessel, then add water and stir for 3.5h-4.5h.

[0023] (3) Add silica sol to the solution obtained in the step (2), and stir; wherein, the parts by weight of the water are 5 parts to 22 parts, and the parts by weight of the silica sol are 0.09 parts to 0.1 parts by weight part; the molar ratio of silicon oxide, aluminum oxide, sodium oxide and water in the silica sol is ...

Embodiment 1

[0028] 1. Mix and grind 0.715g of FCC waste catalyst and 1.7g of sodium hydroxide evenly until no obvious sodium hydroxide particles are observed, then add it into a closed activation reaction vessel, the reaction temperature is 160°C and the reaction time is 1 hour. After the activation reaction is completed, statically Set aside to cool.

[0029] 2. Transfer the powdered solid collected in step 1 to a crystallization reaction vessel, add 22 ml of water, and stir evenly under airtight conditions at room temperature for 4 hours.

[0030] 3. Add 0.1g of silica sol to the mixed solution, and the molar ratio of its active ingredients is SiO 2 :Al 2 o 3 :Na 2 O:H 2 O=1.6:1:2:400.

[0031] 4. The mixture obtained in step 2 was subjected to hydrothermal crystallization, the crystallization temperature was 75° C. and the crystallization time was 12 hours.

[0032] 5. The crystallized product was collected by filtration, washing and drying, wherein the pH of the product after wa...

Embodiment 2

[0035] 1. Mix and grind 0.715g of FCC waste catalyst and 0.5g of sodium hydroxide evenly until no obvious sodium hydroxide particles are observed, then add it into a closed activation reaction vessel, the reaction temperature is 200°C and the reaction time is 4 hours. After the activation reaction is completed, statically Set aside to cool.

[0036] 2. Transfer the powdery solid collected in step 1 to a crystallization reaction vessel, add 5.5 ml of water, and stir evenly under airtight conditions at room temperature for 4 hours.

[0037] 3. Add 0.03g of white carbon black to the mixed solution, and the molar ratio of its active ingredients is SiO 2 :Al 2 o 3 :Na 2 O:H 2 O=1.6:1:2:100.

[0038] 4. The mixture obtained in step 2 was subjected to hydrothermal crystallization, the crystallization temperature was 120° C. and the crystallization time was 4 hours.

[0039] 5. Collect the crystallized product by filtering, washing and drying, wherein the pH of the product after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com