Preparation method of open macroporous Beta molecular sieve

A molecular sieve, open technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as the preparation method of open large-pore Beta molecular sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

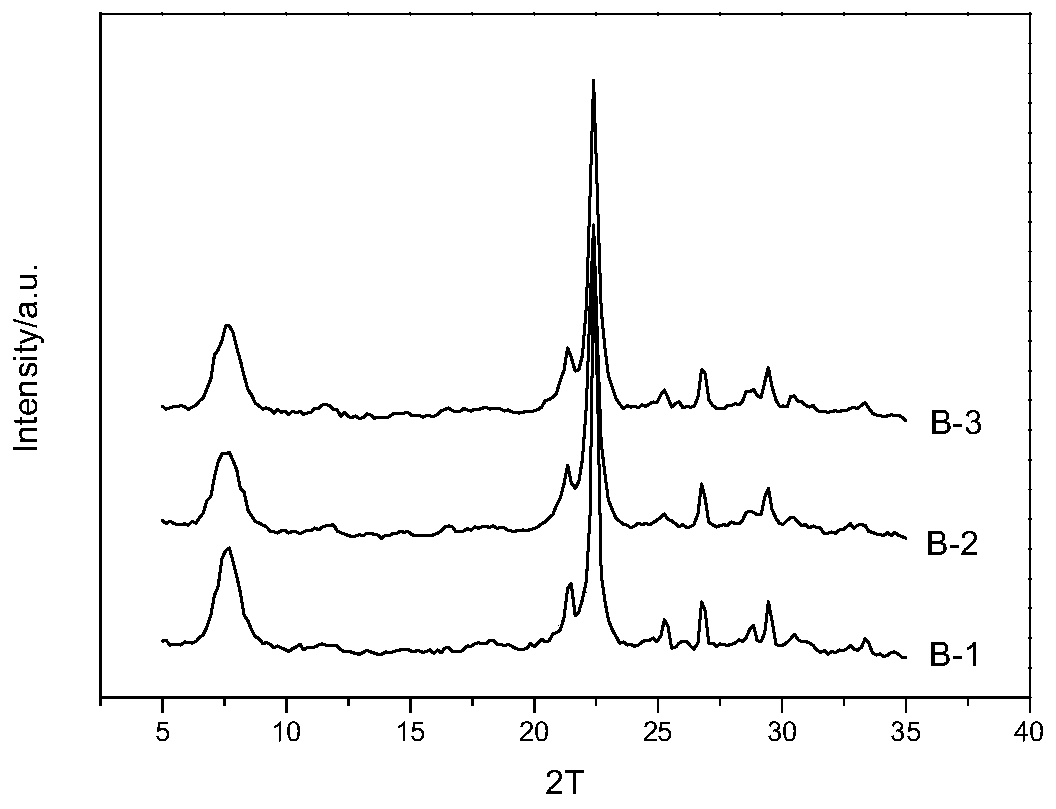

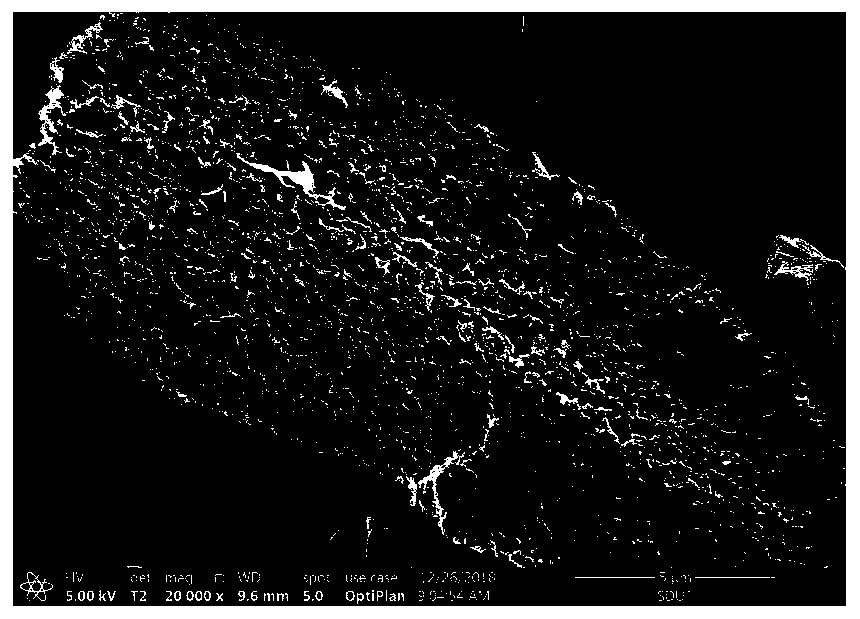

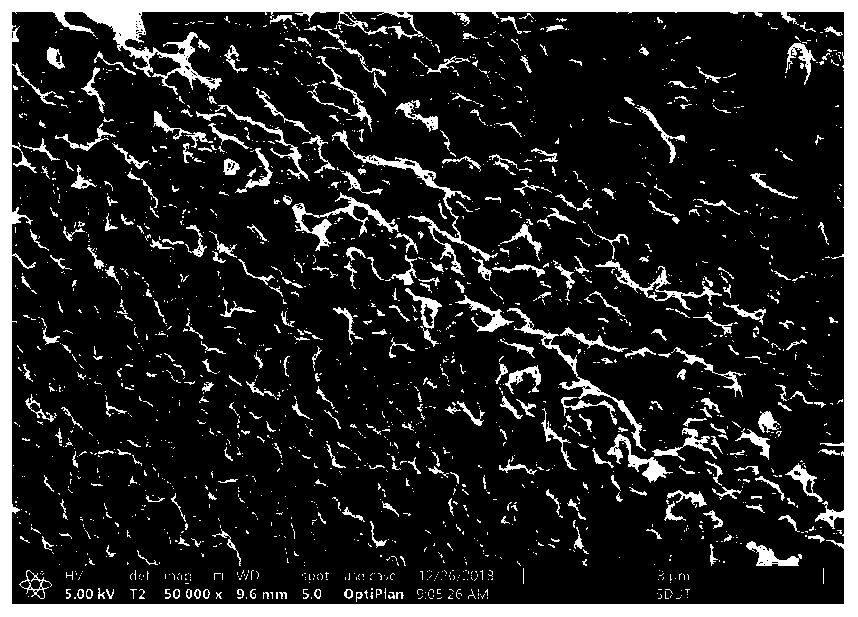

Embodiment 1

[0026] A kind of preparation method of open macropore Beta molecular sieve, comprises the following steps:

[0027] Mix deionized water, aluminum oxide, sodium hydroxide, tetraethylammonium hydroxide (R), cetyltrimethylammonium bromide (X), tetraethyl orthosilicate and seed crystals and transfer to crystal Crystallization in the kettle. The molar ratio of each component in the gel is: SiO 2 :Al 2 o 3 :Na 2 O:TEAOH:X:H 2 O=1:0.03:0.3:0.2:0.001:15. The added mass of seed crystal accounts for 8% of the silica mass in the gel. Rapidly raise the temperature to 160°C with a heating rate of 5°C / min, adjust the back pressure valve to a pressure of 0.3MPa, and keep the temperature constant for 24h. After the crystallization is completed, pass low-temperature cooling water into the crystallization solution at a cooling rate of -4°C / min. After cooling down to room temperature, the crystallized product is separated, washed, dried and calcined to obtain Beta molecular sieve, which ...

Embodiment 2

[0029] A kind of preparation method of open macropore Beta molecular sieve, comprises the following steps:

[0030] Mix deionized water, aluminum isopropoxide, sodium hydroxide, tetraethylammonium bromide (R), ammonium bicarbonate (X), water glass and seed crystals evenly, then transfer to a crystallization tank for crystallization. The molar ratio of each component in the gel is: SiO 2 :Al 2 o 3 :Na 2 O:TEAOH:X:H 2 O=1:0.01:0.05:0.1:0.1:1. The added mass of seed crystal accounts for 7% of the silica mass in the gel. Rapidly raise the temperature to 170°C with a heating rate of 6°C / min, adjust the back pressure valve to a pressure of 0.35MPa, and keep the temperature constant for 12h. After the crystallization is completed, pass low-temperature cooling water into the crystallization solution at a cooling rate of -4°C / min. After cooling down to room temperature, the crystallized product is separated, washed, dried, and calcined to obtain a Beta molecular sieve, which is ...

Embodiment 3

[0033] A kind of preparation method of open macropore Beta molecular sieve, comprises the following steps:

[0034] Mix deionized water, aluminum hydroxide, sodium hydroxide, tetraethylammonium hydroxide (R), isopropanol (X), silica gel and seed crystals evenly and transfer them to a crystallization kettle for crystallization. The molar ratio of each component in the gel is: SiO 2 :Al 2 o 3 :Na 2 O:TEAOH:X:H 2 O=1:0.1:0.1:0.3:0.05:30. The added mass of seed crystal accounts for 9% of the silica mass in the gel. Rapidly raise the temperature to 150°C with a heating rate of 4°C / min, adjust the back pressure valve to a pressure of 0.25MPa, and keep the temperature constant for 36h. After the crystallization is completed, pass low-temperature cooling water into the crystallization solution at a cooling rate of -3°C / min. After cooling down to room temperature, the crystallized product is separated, washed, dried, and calcined to obtain a Beta molecular sieve, which is design...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Orifice diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com