Flame-retardant wood-plastic surface layer compound and preparation method of wood-plastic composite material with flame-retardant wood-plastic surface layer compound

A compound and surface layer technology, applied in the field of wood-plastic materials, can solve the problems of poor adhesion between the flame-retardant coating and the wood-plastic board, affecting the flame-retardant effect of the wood-plastic board, and achieve a small coefficient of friction, improved viscosity, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

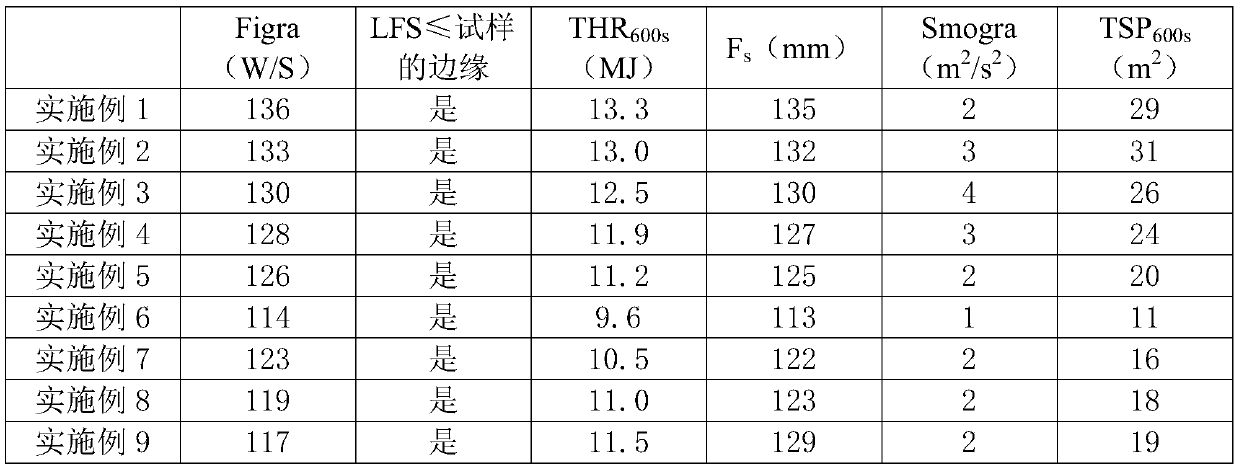

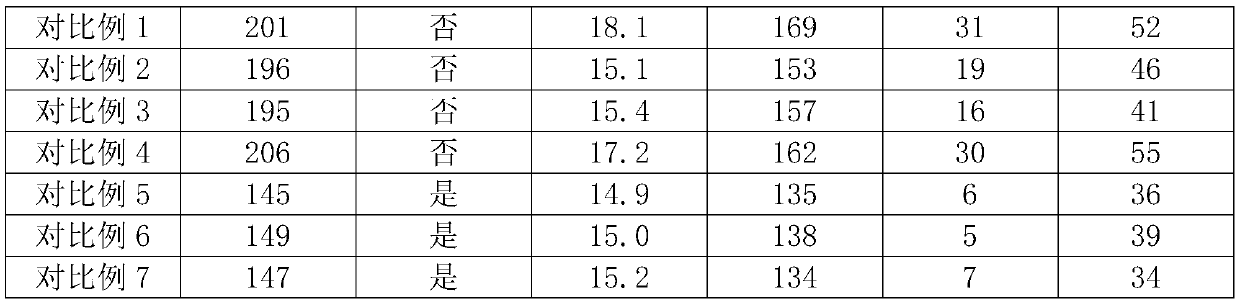

Examples

Embodiment 1

[0035] Table 1 is the raw material and quality of a kind of flame-retardant wood-plastic surface layer composite of embodiment 1

[0036] components mass (kg) components mass (kg) High-density polyethylene 50 Anti-ultraviolet agent 0.5 Polypropylene 10 Toner 1 Ethylene acrylic acid copolymer 50 Thiazolylbenzimidazoles 1.0 filler 10 polyethylene wax 0.8 Decabromodiphenylethane 10 Silicone powder 1.6 Modified Kaolin 6

[0037] Wherein the preparation method of modified kaolin is: 1) 10kg raw kaolin is mixed with 20kg mass fraction of 60wt% urea aqueous solution, then mechanically stirred, and at the same time ultrasonically treated at 100KHz for 6h, after the ultrasonic finishes, washed 5 times, then dried to obtain intercalated modified kaolin; 2) grinding the intercalated modified kaolin prepared in 1), placing it in an oven, and treating it at 140° C. for 1 hour to obtain exfoliated kaolin; 3) 5 kg exfoli...

Embodiment 2

[0044] Table 2 is the raw material and quality of a kind of flame-retardant wood-plastic surface layer composite of embodiment 2

[0045] components mass (kg) components mass (kg) High-density polyethylene 10 Modified Kaolin 0.5 Polypropylene 50 Anti-ultraviolet agent 0.3 Ethylene acrylic acid copolymer 10 Toner 5.5 filler 50 Isothiazolinones 0.8 Aluminum hydroxide 15 polyethylene wax 0.5 Modified montmorillonite 0.5 Silicone powder 2.5

[0046] The preparation method of the modified montmorillonite is as follows: 1) 10 kg of raw material montmorillonite and 40 kg of water are mixed and stirred continuously until the montmorillonite is uniformly dispersed in water, and then heated to 100°C; 2) adding 0.5 kg of montmorillonite to step 1 kg cetyltrimethylammonium bromide, continue to stir for 2h; 3) the mixture of step 2) is suction filtered and washed 3 times, and after drying, organic montmorillonite is obt...

Embodiment 3

[0054] Table 3 is the raw material and quality of a kind of flame-retardant wood-plastic surface layer composite of embodiment 3

[0055] components mass (kg) components mass (kg) High-density polyethylene 25 Modified Kaolin 0.7 Polypropylene 20 Anti-ultraviolet agent 0.4 Ethylene acrylic acid copolymer 20 Toner 6 filler 20 Thiazolylbenzimidazoles 0.9 Decabromodiphenylethane 11 Stearate 0.3 Melamine cyanurate 4 Silicone powder 2.1 Modified montmorillonite 0.5

[0056] The preparation method of the modified montmorillonite is as follows: 1) Mix 10kg of raw material montmorillonite with 60kg of water and stir continuously until the montmorillonite is evenly dispersed in water, and then heat to 100°C; 2) add 0.8kg octadecyltrimethylammonium chloride, continue to stir for 3h; 3) the mixture of step 2) is suction filtered, washed 4 times, and dried to obtain organic montmorillonite, which is ground thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com