Preparation method of medium-voltage gradient zinc oxide piezoresistor MOV chip

A varistor, voltage gradient technology, applied in the manufacture of resistor chips, resistor manufacturing, resistors, etc., can solve problems such as SPD safety tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

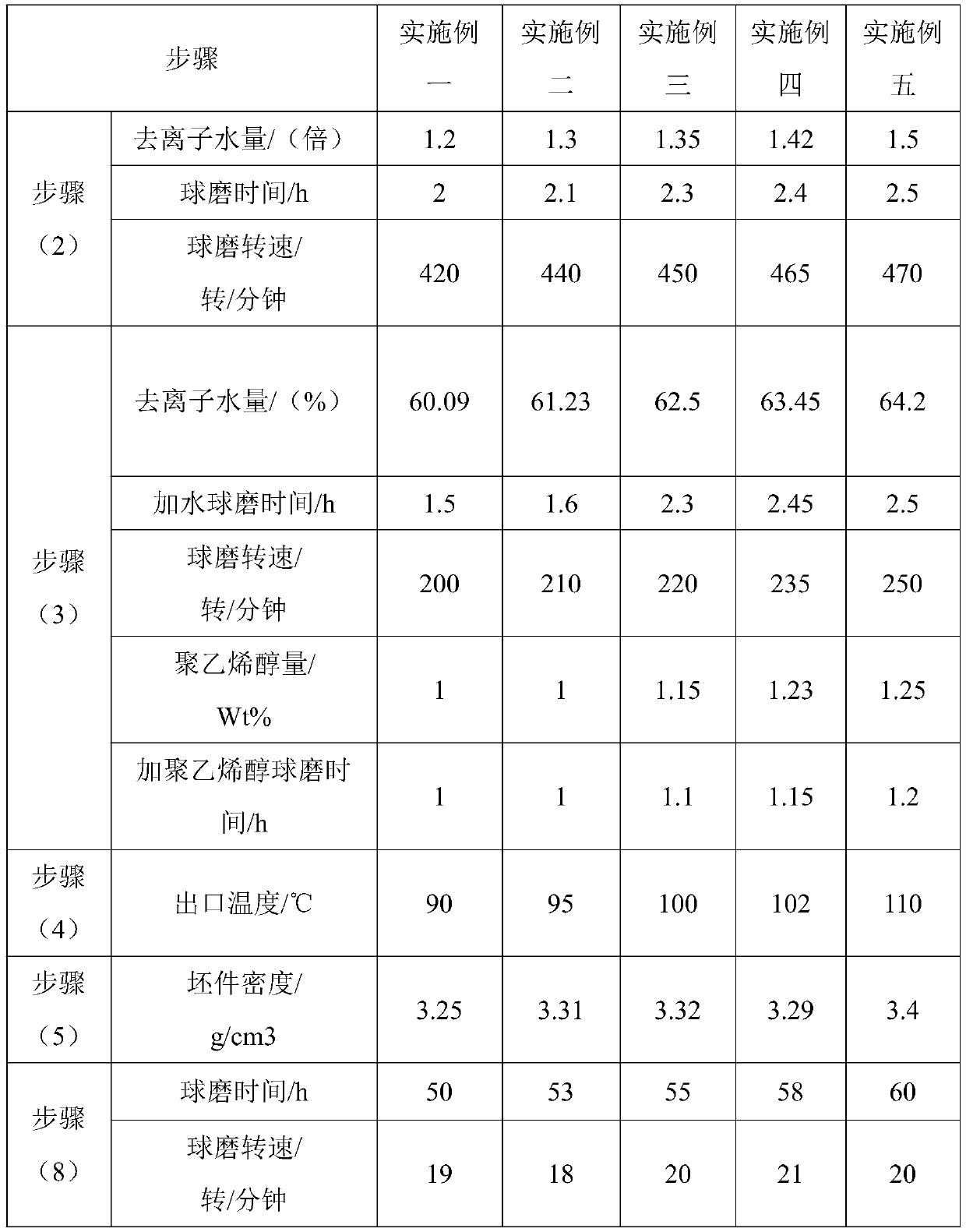

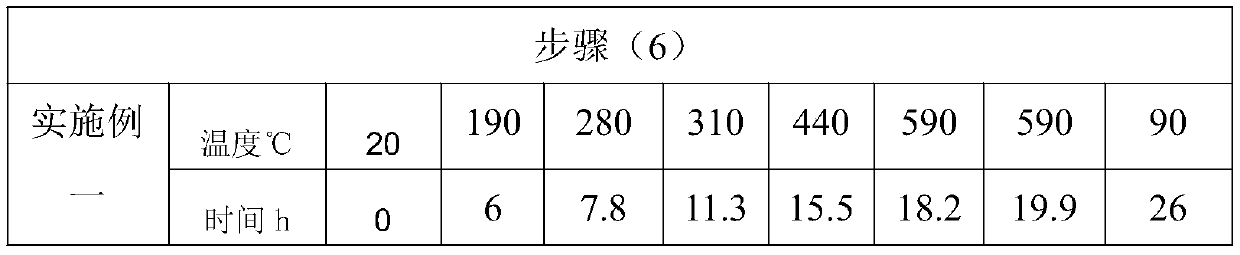

[0077] A method for preparing a medium voltage gradient zinc oxide varistor MOV chip, comprising the following steps:

[0078] (1) Raw material preparation: zinc oxide: 88.25-91.03wt%, bismuth oxide: 3.17-4.89wt%, antimony oxide: 3.67-4.405wt%, cobalt oxide: 1.1-1.51wt%, manganese oxide: 0.7-0.9wt% , nickel oxide: 0.3-0.5wt%; aluminum nitrate: 0.02-0.05wt%, silver nitrate: 0.01-0.021wt%.

[0079] (2) Mixed grinding of doping materials: Mix all the raw materials, and the mixture of bismuth oxide, antimony oxide, cobalt oxide, manganese oxide, nickel oxide, aluminum nitrate and silver nitrate is the base material, and take 1.2-1.5 times the weight of the base material Deionized water, using deionized water as a solvent, conduct water-soluble ball milling on all raw materials for 2-2.5 hours, and the rotating speed of the ball mill is 420-470 rpm.

[0080] (3) continued ball mill: get the deionized water of zinc oxide weight 60.9-64.2wt%, add deionized water in the ball mill in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com