Sulfonated graphene oxide-based single-ion polymer electrolyte separator and its preparation method and application

A technology of electrolyte diaphragm and polymer, which is applied in the field of electrochemistry, can solve the problems of unfavorable electrolyte adsorption and retention, large lithium salt concentration gradient, explosion, etc., achieve excellent thermal dimensional stability, good rate performance, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] (i) Preparation of cathode material

[0065] The positive electrode material used in the present invention is lithium iron phosphate positive electrode, and the active material LiFePO 4 , the mixture of conductive agent acetylene black and binder PVDF is uniformly dissolved in NMP, uniformly mixed at a mass ratio of 7:2:1, and stirred for 12h, during which ultrasonic treatment is performed three times for 20min each time to obtain a yogurt-like viscous slurry, The slurry was then poured onto a flat aluminum foil and spread evenly with a doctor blade. After the solvent was fully evaporated, it was cut into discs with a diameter of 15 mm with a punching machine, and vacuum-dried at 60° C. for 24 h for use in button batteries.

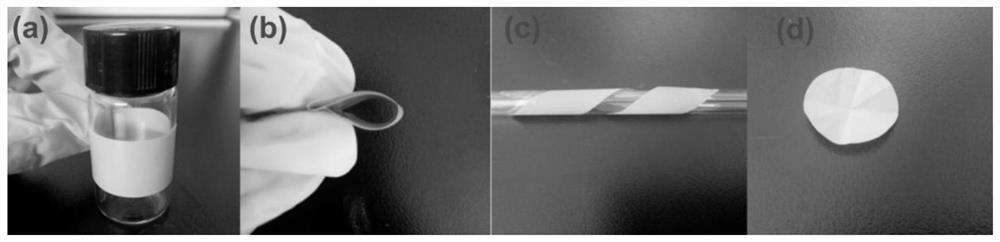

[0066] (ii) Assembly of coin cell batteries

[0067] In the present invention, a CR2025 type button battery is used for testing, and lithium iron phosphate is used as the positive electrode material, the prepared single-ion polymer electrolyte me...

Embodiment 1

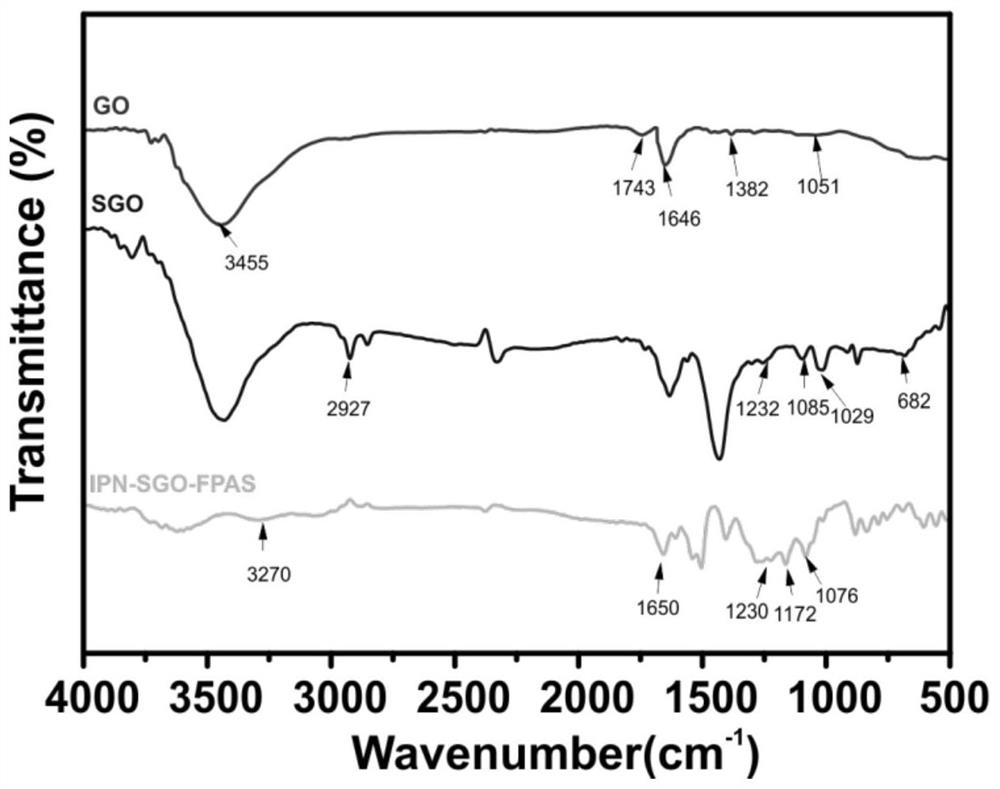

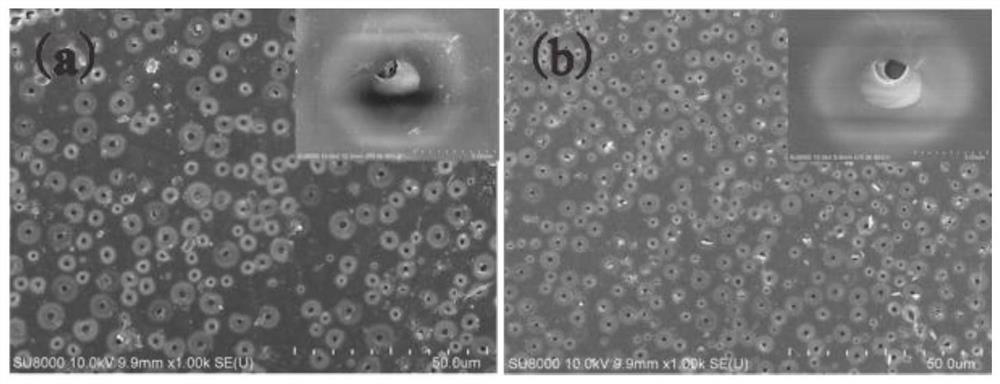

[0071] A method for preparing a single-ion polymer electrolyte membrane based on sulfonated graphene oxide in this embodiment, the method specifically includes the following steps:

[0072] (1) Synthesis of precursor bis(4-carbonylbenzenesulfonyl)imide (CBSI)

[0073](a) The specific synthesis process of the precursor bis(4-carbonylbenzenesulfonyl)imide (CBSI) is shown in formula 1. Take 0.1145mol p-toluenesulfonamide, 0.1202mol lithium hydroxide, and 0.0573mol water in a 250mL double-necked flask, heat to 95°C until all dissolved, then slowly add 0.0573mol p-toluenesulfonyl chloride, add it for about 2 hours, and let it stand overnight. After the reaction temperature dropped to 45°C, the pH was adjusted to 7.0 with 1 mol / L HCl, left standing overnight, filtered, the filter cake was p-toluenesulfonamide, dried and stored, and the filtrate was added dropwise with concentrated hydrochloric acid until no precipitate was produced, filtered, and the The cake was recrystallized wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com