Preparation method and application of multifunctional double-layer nanowire layered composite material

A layered composite material and nanowire technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, electrodes, etc., can solve the problems of limiting large-scale practical applications, high cost and scarcity, and achieve high surface capacitance characteristics, high production efficiency, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 10 mg of graphene oxide into 30 mL of distilled water by ultrasound, after ultrasonication for 1 h to form a uniform brown solution, add 30 mg of ascorbic acid, after ultrasonic stirring, place the cleaned nickel foam in the dispersion, and put it in a water bath at 90 °C After deposition for 6 hours under the same conditions, the surface of the sample was rinsed with deionized water after removal, and dried at 60 °C for 12 h to obtain rGO / NF.

Embodiment 2

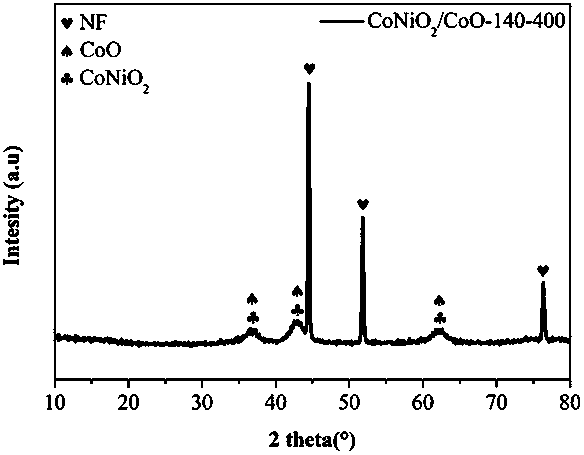

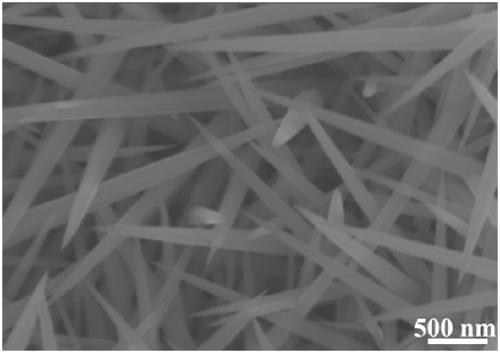

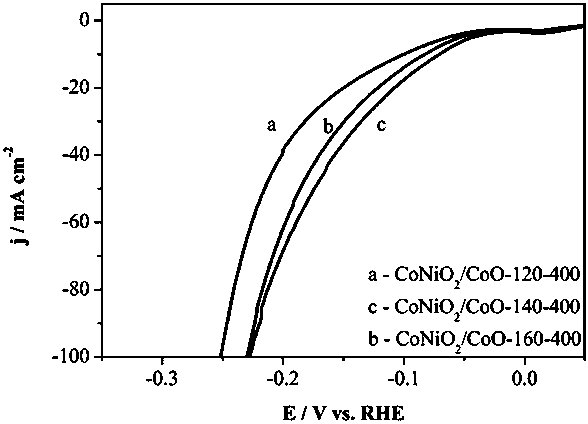

[0029] Put rGO / NF in 1.019g Co(NO 3 ) 2 ·6H 2 O and 1.051g urea were mixed to form a 35mL homogeneous solution, which was fully reacted in a box furnace at 120°C for 10h to form a CoO nanowire precursor; the precursor was placed in a solution containing 1.5mmol Co(NO 3 ) 2 ·6H 2 O, 1.5mmol Ni(NO 3 ) 2 ·6H 2 0, 15mmol urea and 8mmol ammonium fluoride 30mL homogeneously mixed solution, transferred to polytetrafluoroethylene lining and placed in a 140 ℃ box furnace to react, keep warm for 6h, take out the sample to obtain the double-layer nanowire precursor, after 400 °C annealing to obtain layered CoNiO 2 / CoO-140-400 material.

Embodiment 3

[0031] Put rGO / NF in 1.019g Co(NO 3 ) 2 ·6H 2 O and 1.051g urea were mixed to form a 35mL homogeneous solution, which was fully reacted in a box furnace at 120°C for 10h to form a CoO nanowire precursor; the precursor was placed in a solution containing 1.5mmol Co(NO 3 ) 2 ·6H 2 O, 1.5mmol Ni(NO 3 ) 2 ·6H 2 30mL homogeneously mixed solution of 0, 15mmol urea and 8mmol ammonium fluoride was transferred to a polytetrafluoroethylene lining and placed in a 120°C box-type furnace for reaction. °C annealing to obtain layered CoNiO 2 / CoO-120-400 material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com