Flame-retardant mildew-proof powder coating based on environmental protection

A powder coating and anti-mildew technology, applied in the field of coatings, can solve the problems of no flame retardant performance, single function, easy to mold and bacteria, etc., achieve long-term flame retardant and mildew resistance, improve flame retardant performance, and increase flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] raw material:

[0032] 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide: CAS number: 35948-25-5; source: Bailingwei Technology Co., Ltd.;

[0033] [4-[2-(Dimethylamino)ethoxy]phenyl](4-hydroxyphenyl)methanone: CAS number: 173163-13-8; source: Bailingwei Technology Co., Ltd.;

[0034] 1-Phenyl-1,2-ethanediol: (R)-(-)-1-phenyl-1,2-ethanediol, CAS number: 16355-00-3; source: Bailingwei Technology Co., Ltd. ;

[0035] Phosphorus oxychloride: GR;

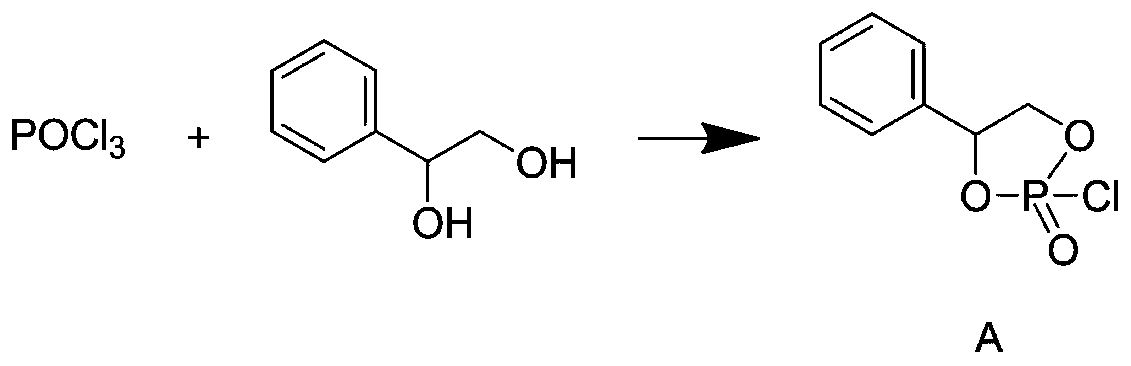

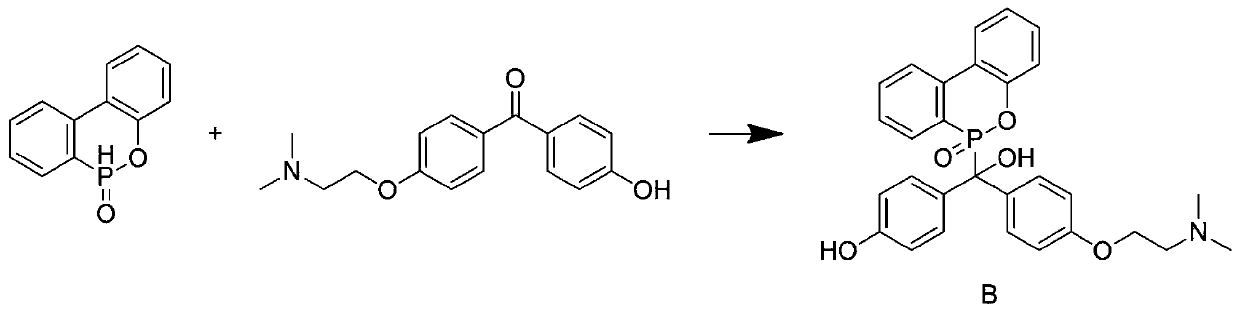

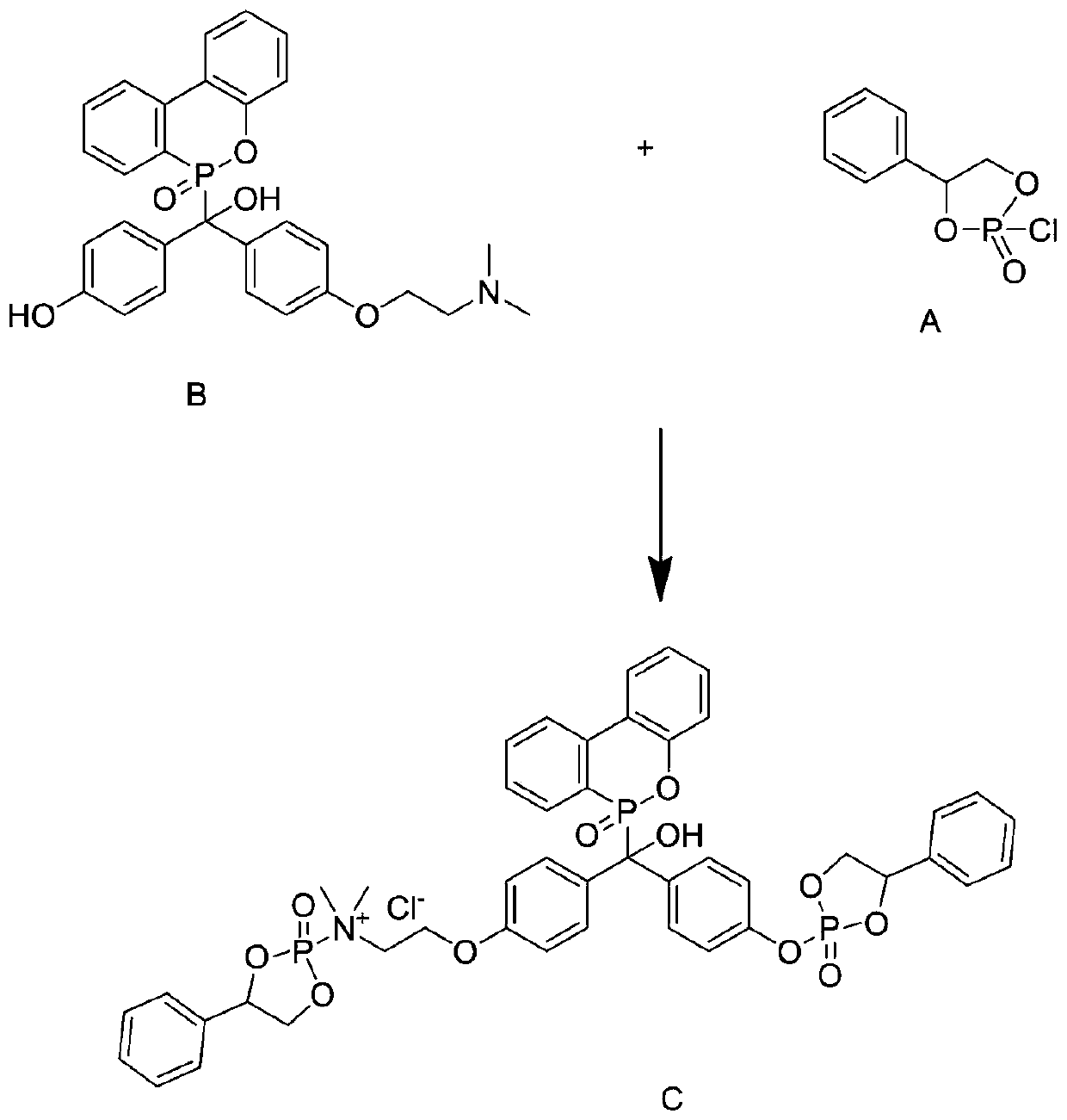

[0036] see Figure 1-3 Shown, the preparation method of flame retardant antifungal agent is:

[0037] Step 1. Add 1.05mol of phosphorus oxychloride and 1mol of 1-phenyl-1,2-ethanediol into the reaction flask, replace the air in the reaction flask with nitrogen gas, heat up to 80°C while stirring, and keep the temperature for reaction 5h, naturally cooled to room temperature, filtered, washed 5 times with anhydrous ether, and dried in vacuum to obtain Compound A; the yield was 95.4%;

[0038] Detected by GC-MS: Compound A (...

Embodiment 2

[0044] A kind of flame-retardant anti-mildew powder coating based on environmental protection, comprises the raw material of following weight part: Acrylic resin 60g, polyvinyl alcohol 15g, diatomite 4g, titanium dioxide 10g, negative oxygen ion powder 1g, flame-retardant anti-mold agent 4g, hard Magnesium fatty acid 2g, leveling agent 1g, benzoin 1g;

[0045] The leveling agent is PV88 from German Dexinli Chemical;

[0046] The preparation method of the flame-retardant mildew-proof powder coating is as follows:

[0047] The first step, pre-mixing: Put the raw materials of each component into the mixing tank together, pre-mix for 5 minutes*3 times, and put them into a ball mill for grinding for 20 minutes after mixing;

[0048] The second step, melt extrusion: put the ground powder into the extruder, extrude and tablet, the extrusion temperature is 100°C in the first zone, and 115°C in the second zone, and then crushed by the crusher, grinded by the grinder, and rotated Sub-...

Embodiment 3

[0050] A flame-retardant and anti-mildew powder coating based on environmental protection, including the following raw materials in parts by weight: 80g of acrylic resin, 20g of polyvinyl alcohol, 6g of diatomite, 12g of titanium dioxide, 1.5g of negative oxygen ion powder, 7g of flame-retardant and anti-mold agent, Magnesium stearate 2g, leveling agent 0.5g, benzoin 1.5g;

[0051] The leveling agent is PV88 from German Dexinli Chemical;

[0052] The preparation method of the flame-retardant mildew-proof powder coating is as follows:

[0053] The first step, pre-mixing: Put the raw materials of each component into the mixing tank together, pre-mix for 5 minutes*3 times, and put them into a ball mill for grinding for 30 minutes after mixing;

[0054] The second step, melt extrusion: put the ground powder into the extruder, extrude and tablet, the extrusion temperature is 105°C in the first zone, and 120°C in the second zone, and then crushed by the crusher, grinded by the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com