A kind of flame-retardant anti-mildew powder coating based on environmental protection

A powder coating and anti-mildew technology, applied in the field of coatings, can solve the problems of no flame retardant performance, single function, easy to mold and bacteria, etc., achieve long-term flame retardant and mildew resistance, improve flame retardant performance, and increase flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] raw material:

[0032] 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide: CAS number: 35948-25-5; source: Bailingwei Technology Co., Ltd.;

[0033] [4-[2-(Dimethylamino)ethoxy]phenyl](4-hydroxyphenyl)methanone: CAS number: 173163-13-8; source: Bailingwei Technology Co., Ltd.;

[0034] 1-Phenyl-1,2-ethanediol: (R)-(-)-1-phenyl-1,2-ethanediol, CAS number: 16355-00-3; source: Bailingwei Technology Co., Ltd. ;

[0035] Phosphorus oxychloride: GR;

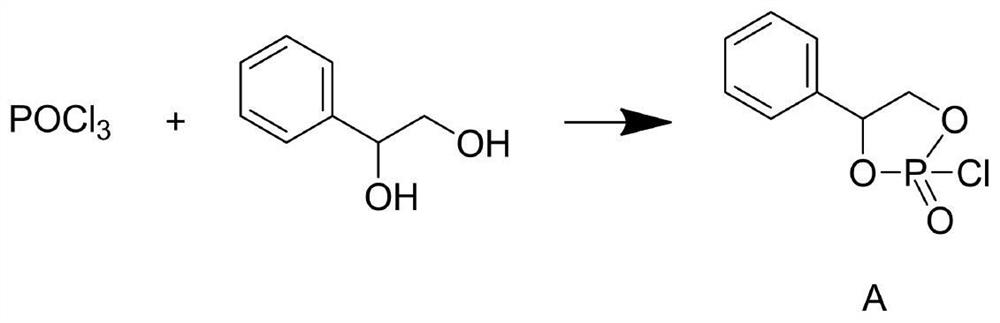

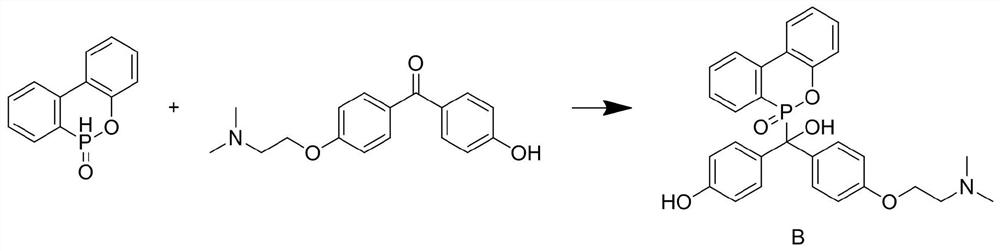

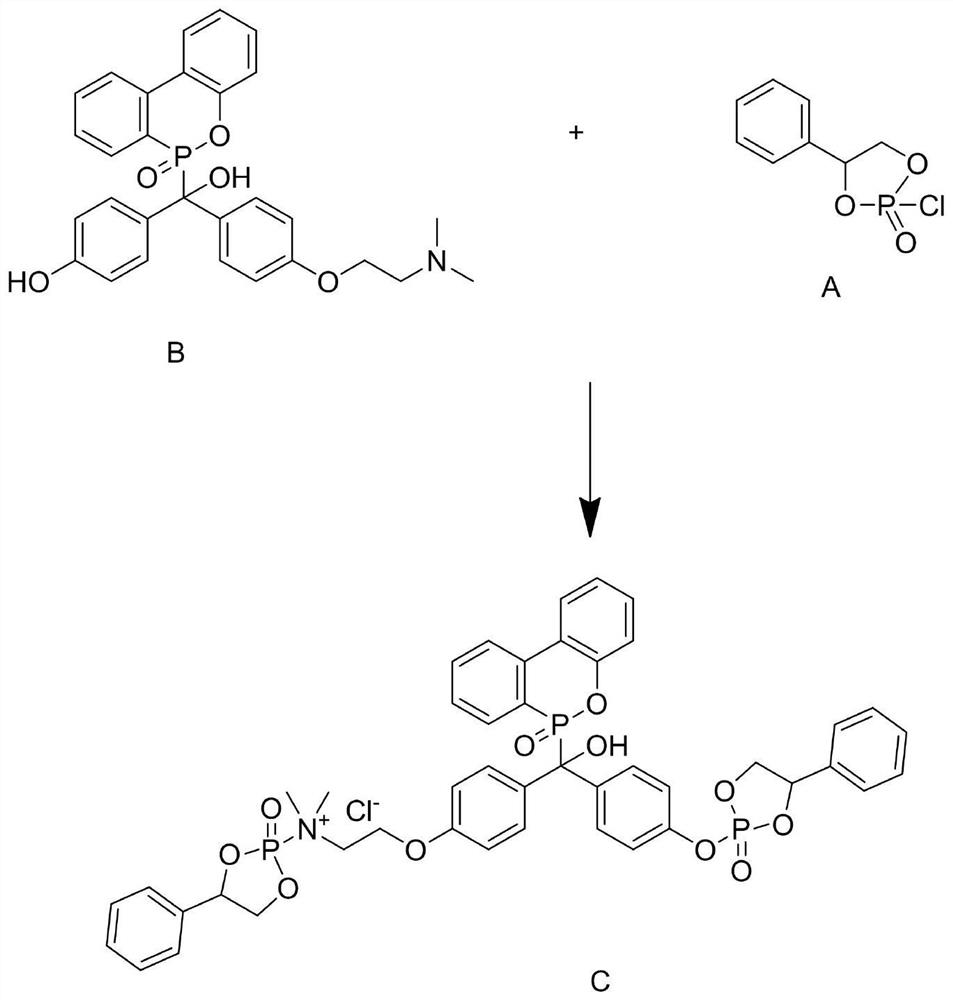

[0036] see Figure 1-3 Shown, the preparation method of flame retardant antifungal agent is:

[0037] Step 1. Add 1.05mol of phosphorus oxychloride and 1mol of 1-phenyl-1,2-ethanediol into the reaction flask, replace the air in the reaction flask with nitrogen gas, heat up to 80°C while stirring, and keep the temperature for reaction 5h, naturally cooled to room temperature, filtered, washed 5 times with anhydrous ether, and dried in vacuum to obtain Compound A; the yield was 95.4%;

[0038] Detected by GC-MS: Compound A (...

Embodiment 2

[0044] A kind of flame-retardant anti-mildew powder coating based on environmental protection, comprises the raw material of following weight part: Acrylic resin 60g, polyvinyl alcohol 15g, diatomite 4g, titanium dioxide 10g, negative oxygen ion powder 1g, flame-retardant anti-mold agent 4g, hard Magnesium fatty acid 2g, leveling agent 1g, benzoin 1g;

[0045] The leveling agent is PV88 from German Dexinli Chemical;

[0046] The preparation method of the flame-retardant mildew-proof powder coating is as follows:

[0047] The first step, pre-mixing: Put the raw materials of each component into the mixing tank together, pre-mix for 5 minutes*3 times, and put them into a ball mill for grinding for 20 minutes after mixing;

[0048] The second step, melt extrusion: put the ground powder into the extruder, extrude and tablet, the extrusion temperature is 100°C in the first zone, and 115°C in the second zone, and then crushed by the crusher, grinded by the grinder, and rotated Sub-...

Embodiment 3

[0050] A flame-retardant and anti-mildew powder coating based on environmental protection, including the following raw materials in parts by weight: 80g of acrylic resin, 20g of polyvinyl alcohol, 6g of diatomite, 12g of titanium dioxide, 1.5g of negative oxygen ion powder, 7g of flame-retardant and anti-mold agent, Magnesium stearate 2g, leveling agent 0.5g, benzoin 1.5g;

[0051] The leveling agent is PV88 from German Dexinli Chemical;

[0052] The preparation method of the flame-retardant mildew-proof powder coating is as follows:

[0053] The first step, pre-mixing: Put the raw materials of each component into the mixing tank together, pre-mix for 5 minutes*3 times, and put them into a ball mill for grinding for 30 minutes after mixing;

[0054] The second step, melt extrusion: put the ground powder into the extruder, extrude and tablet, the extrusion temperature is 105°C in the first zone, and 120°C in the second zone, and then crushed by the crusher, grinded by the grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com