Environmental-friendly paint containing plant additives and preparation method thereof

A plant additive and environmentally friendly paint technology, applied in the field of paint, can solve the problems of inability to further improve indoor air, complex production process, affecting human health, etc., and achieve the effects of improving indoor odor, good dispersion uniformity, and improving efficacy duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

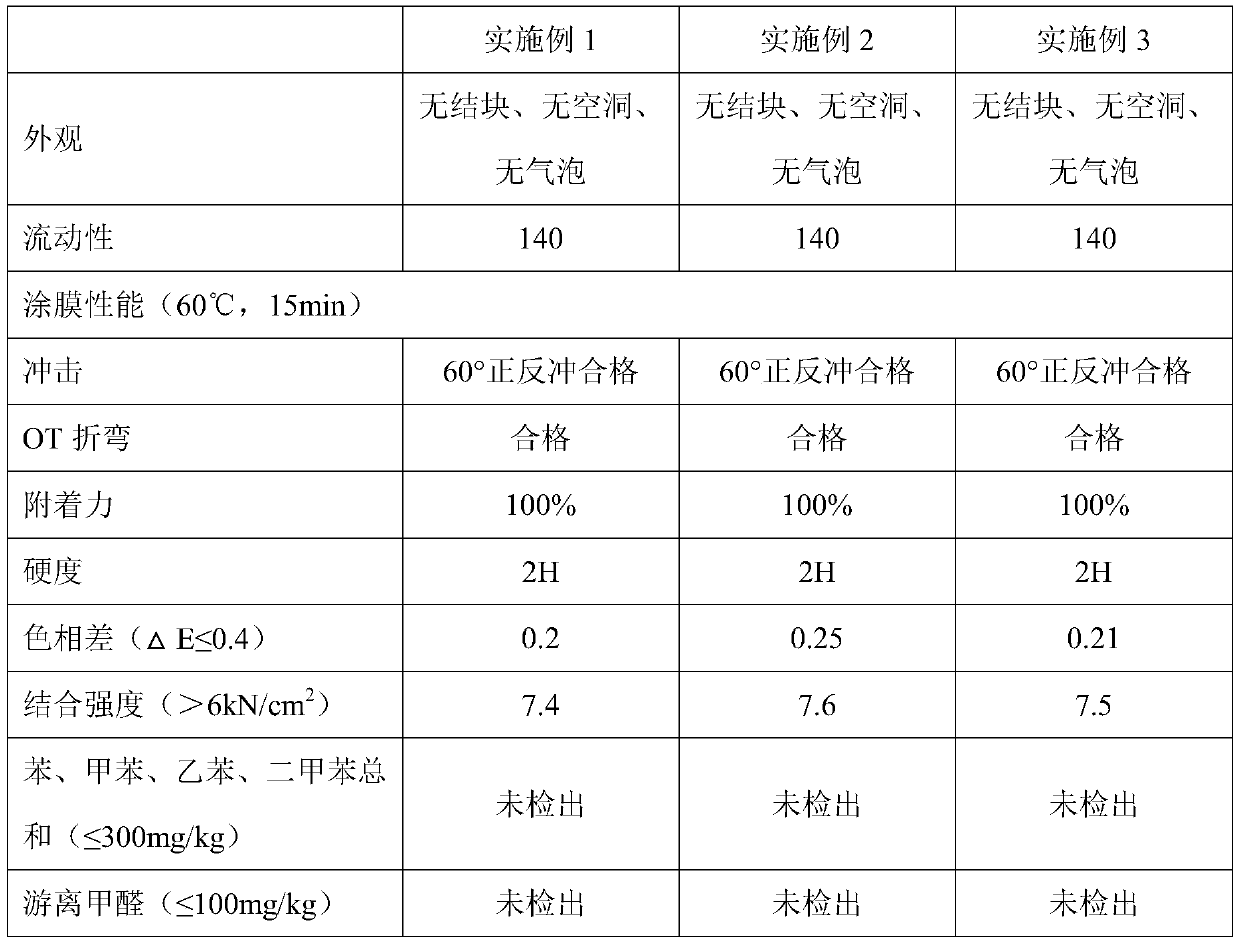

Examples

Embodiment 1

[0029] S1, preparing plant additives.

[0030] Take golden kudzu, aloe vera, cactus, mint, fragrant wood leaves, Chuanqiong, rhodiola, Sophora japonica, Ginkgo biloba, Haematococcus pluvialis, green tea and Acanthopanax rhizomes are washed separately, then dried, dehydrated and ground The powder is ready for use; the metal fiber is pulverized and sieved through a 100-mesh sieve plate, and then the above-mentioned powders are 10 parts by mass of golden arrowroot powder, 10 parts of aloe powder, 6 parts of cactus powder, 5 parts of peppermint powder, and fragrant wood powder. 10 parts of leaf powder, 10 parts of Chuanqiong powder, 10 parts of Rhodiola powder, 10 parts of Sophora japonica powder, 10 parts of Ginkgo biloba powder, 5 parts of Haematococcus pluvialis powder, 10 parts of green tea powder, 10 parts of Acanthopanax rhizome powder 1 part of metal fiber and 1 part of metal fiber, add water and stir evenly to obtain plant additives.

[0031] S2. Prepare modified triethyl...

Embodiment 2

[0035] S1, preparing plant additives.

[0036] Take golden kudzu, aloe vera, cactus, mint, fragrant wood leaves, Chuanqiong, rhodiola rosea, Sophora japonica, ginkgo biloba, seaweed, green tea and Acanthopanax rhizomes are washed separately, then dried, dehydrated, and ground into powder for later use; After the metal fiber is pulverized, it is sieved through a 100-mesh sieve plate, and then the above-mentioned powders are divided into 10 parts of golden arrowroot powder, 10 parts of aloe powder, 6 parts of cactus powder, 5 parts of peppermint powder, and 10 parts of Qingxiang wood leaf powder in parts by mass. , 10 parts of Chuanqiong powder, 10 parts of rhodiola powder, 10 parts of Huaihua powder, 10 parts of ginkgo leaf powder, 5 parts of seaweed powder, 10 parts of green tea powder, 10 parts of Acanthopanax rhizome powder and 1 part of metal fiber mixing, adding water and stirring evenly to obtain the plant additive.

[0037] S2. Prepare modified triethylenetetramine.

...

Embodiment 3

[0041] S1, preparing plant additives.

[0042]Take golden kudzu, aloe vera, cactus, mint, fragrant wood leaves, Chuanqiong, rhodiola, Sophora japonica, Ginkgo biloba, Haematococcus pluvialis, green tea and Acanthopanax rhizomes are washed separately, then dried, dehydrated and ground The powder is ready for use; the metal fiber is pulverized and sieved through a 100-mesh sieve plate, and then the above-mentioned powders are 10 parts by mass of golden arrowroot powder, 15 parts of aloe powder, 8 parts of cactus powder, 8 parts of peppermint powder, and 8 parts of fragrant wood powder. 15 parts of leaf powder, 15 parts of Chuanqiong powder, 10 parts of Rhodiola powder, 10 parts of Sophora japonica powder, 10 parts of Ginkgo biloba powder, 5 parts of Haematococcus pluvialis powder, 10 parts of green tea powder, 10 parts of Acanthopanax rhizome powder 1 part of metal fiber and 1 part of metal fiber, add water and stir evenly to obtain plant additives.

[0043] S2. Prepare modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com