Soybean paste based on pre-fermentation and using Monascus purpureus as dominant fungus symbiotic system, and preparation method thereof

A technology of Monascus purpura and a production method, which is applied in the field of condiment production, can solve the problems of unclear flavor substances of soybean paste, difficulty in standardization, and long production cycle, so as to prevent the occurrence of cardiovascular diseases, promote the growth of dominant bacteria, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

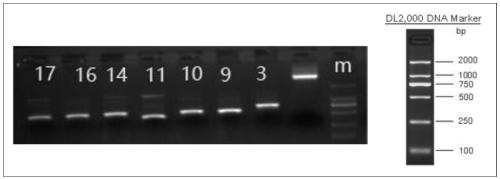

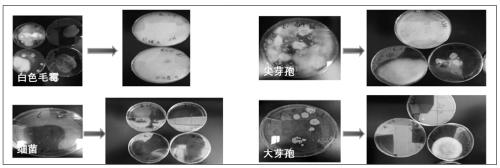

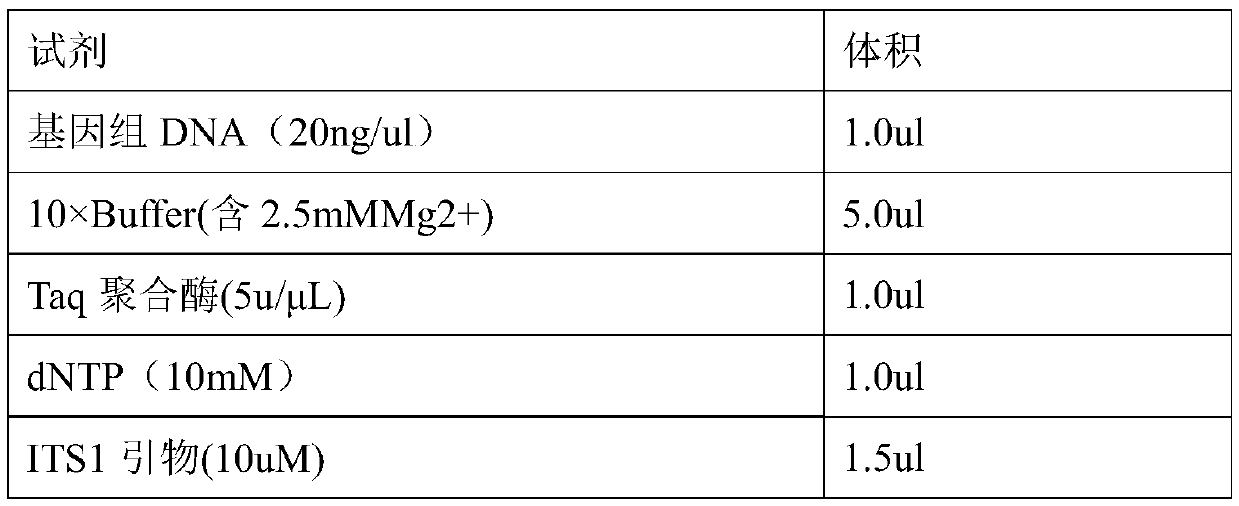

Method used

Image

Examples

Embodiment 1

[0067] is produced by the following steps:

[0068] Step 1. Selected soybean Suinong 29, with a protein content of 41.92% and a fat content of 21.28%, was mechanically graded and selected;

[0069] Step 2, steaming to remove fishy smell: Steaming at 120°C for 3 minutes;

[0070] Step 3. Cooking and maturation of the sugar liquid: Add 0.5% β-glucan solution for high-temperature aging. The amount of the solution added is 1.5 times the volume of the dry beans, and the high-temperature aging is carried out. The aging parameters are 100°C for 35 minutes. After aging, cool down for later use;

[0071] Step 4, enzymatic hydrolysis: adding neutral protease and transglutaminase to carry out compound modification on soybean protein; mixing ratio neutral protease:transglutaminase=1:1.5, temperature 55°C, time 0.5h, pH7.0, enzyme dosage is 2.5% of the whole material weight in the previous step;

[0072] Step 5, rolling: transfer the material to the chopping machine for full rolling;

...

Embodiment 2

[0084] is produced by the following steps:

[0085] Step 1. Selected soybean Suinong 29, with a protein content of 41.92% and a fat content of 21.28%, was mechanically graded and selected;

[0086] Step 2, steaming to remove fishy smell: steaming at 120°C for 4in;

[0087] Step 3. Cooking and maturation of the sugar liquid: Add 0.7% β-glucan solution for high-temperature aging. The amount of solution added is 2.0% of the volume of dry beans. High-temperature aging is carried out. The aging parameters are 100°C for 37.5 minutes. After aging, cool down for later use;

[0088] Step 4, enzymatic hydrolysis: adding neutral protease and transglutaminase to carry out compound modification on soybean protein; mixing ratio neutral protease:transglutaminase=1:1.5, temperature 55°C, time 0.5h, pH7.0, enzyme dosage are 3.7% of the whole material weight in the previous step;

[0089] Step 5, rolling: transfer the material to the chopping machine for full rolling;

[0090] Step 6. One-ti...

Embodiment 3

[0101] is produced by the following steps:

[0102] Step 1. Selected soybean Suinong 29, with a protein content of 41.92% and a fat content of 21.28%, was mechanically graded and selected;

[0103] Step 2, steaming to remove fishy smell: steaming at 120°C for 5 minutes;

[0104] Step 3. Cooking and maturation of the sugar solution: Add 1% β-glucan solution for high-temperature aging. The amount of the solution added is 2.5 times the volume of the dry beans, and the high-temperature aging is carried out. The aging parameters are 100°C for 40 minutes. After aging, cool down for later use;

[0105] Step 4, enzymatic hydrolysis: adding neutral protease and transglutaminase to carry out compound modification on soybean protein; mixing ratio neutral protease:transglutaminase=1:1.5, temperature 55°C, time 0.5h, pH7.0, enzyme dosage is 5% of all materials weight in the previous step;

[0106] Step 5, rolling: transfer the material to the chopping machine for full rolling;

[0107] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com