Application of HEH in catalyzing reaction of aryl halogen and aryl sulfinate to prepare sulfone compounds

A technology of aryl sulfinate and aryl halogen, which is applied in the field of catalytic chemistry, can solve the problems of high reduction potential and achieve high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

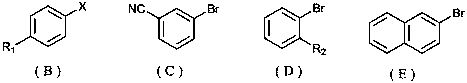

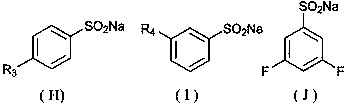

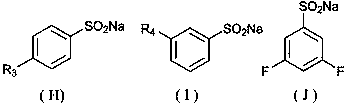

[0027] Example 1: The HEH catalytic system catalyzes the reaction of 4-cyanohalobenzene and sodium benzenesulfinate.

[0028]

[0029] 4-cyanohalobenzene (X = Cl, Br, Cl, 0.2 mmol), sodium benzenesulfinate (0.4 mmol), Cs 2 CO 3 (0.3mmol), HEH (20 mol%, 0.04 mmol) and DMSO (1 mL) were added to a dry reaction tube with a magnetic stirrer, and then the reaction tube was washed with N 2 Replaced 3 times, stirred and reacted for 24 h under the irradiation of blue LED. After the reaction, 5 mL of water was added, then extracted with 3×5 mL of ethyl acetate, the organic phases were combined, and the organic phase was dried with anhydrous sodium sulfate, filtered, and the filtrate was concentrated by rotary evaporation and separated by silica gel column chromatography. The target product (X = I, yield 95%; X = Br, yield 92%; X = Cl, yield 83%) was obtained.

[0030] 1 H-NMR (400 MHz, CDCl 3 , ppm): δ 8.05 (d, J = 7.9 Hz, 2H), 7.95 (d, J =7.7 Hz, 2H), 7.80 (d, J = 8.0 Hz,...

Embodiment 2

[0031] Example 2: The HEH catalytic system catalyzes the reaction of 4-acetylbromobenzene and sodium benzenesulfinate.

[0032]

[0033] 4-Acetylbromobenzene (0.2 mmol), sodium benzenesulfinate (0.4 mmol), Cs 2 CO 3 (0.3 mmol), HEH (20mol%) and DMSO (1 mL) were added to a dry reaction tube with a magnetic stirrer, and then the reaction tube was washed with N 2 Replaced 3 times, stirred and reacted for 24 h under the irradiation of blue LED. After the reaction, 5 mL of water was added, then extracted with 3×5 mL of ethyl acetate, the organic phases were combined, and the organic phase was dried with anhydrous sodium sulfate, filtered, and the filtrate was concentrated by rotary evaporation and separated by silica gel column chromatography. The target product was obtained (91% yield). Cs 2 CO 3 Replaced with potassium carbonate, the rest remained unchanged, to obtain the target product (yield 90%).

[0034] 1 H-NMR (400 MHz, CDCl 3 , ppm): δ 8.09–8.01 (m, 4H), 7.96 (d...

Embodiment 3

[0036] Embodiment 3: HEH catalytic system catalyzes the reaction of methyl 4-bromobenzoate and sodium benzene sulfinate.

[0037]

[0038] Methyl 4-bromobenzoate (0.2 mmol), sodium benzenesulfinate (0.4 mmol), Cs 2 CO 3(0.3 mmol), HEH (20 mol%) and DMSO (1 mL) were added to a dry reaction tube with a magnetic stirrer, and then the reaction tube was washed with N 2 Replaced 3 times, stirred and reacted for 24 h under the irradiation of blue LED. After the reaction, 5 mL of water was added, then extracted with 3×5 mL of ethyl acetate, the organic phases were combined, and the organic phase was dried with anhydrous sodium sulfate, filtered, and the filtrate was concentrated by rotary evaporation and separated by silica gel column chromatography. The target product was obtained (91% yield).

[0039] 1 H-NMR (400 MHz, CDCl 3 , ppm): δ 8.15 (d, J = 8.3 Hz, 2H), 8.02 (d, J =8.3 Hz, 2H), 7.96 (d, J = 7.6 Hz, 2H), 7.60 (t, J = 7.2 Hz, 1H), 7.53 (t, J =7.5 Hz, 2H), 3.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com