Fluidization hydrogenation process for preparing hydrogen peroxide by anthraquinone method

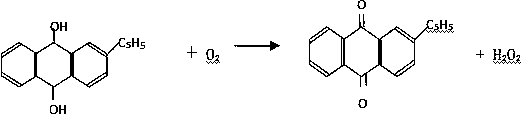

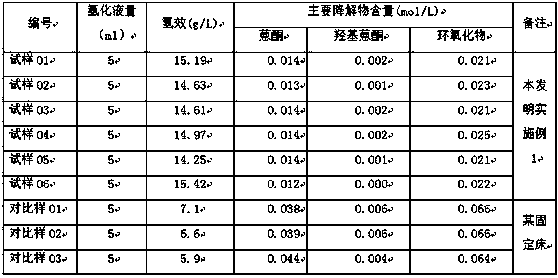

An anthraquinone method and water flow technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of increased cost and slow reaction speed , working fluid loss and other problems, to achieve the effect of improving the use efficiency, moderate hydrogenation efficiency and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

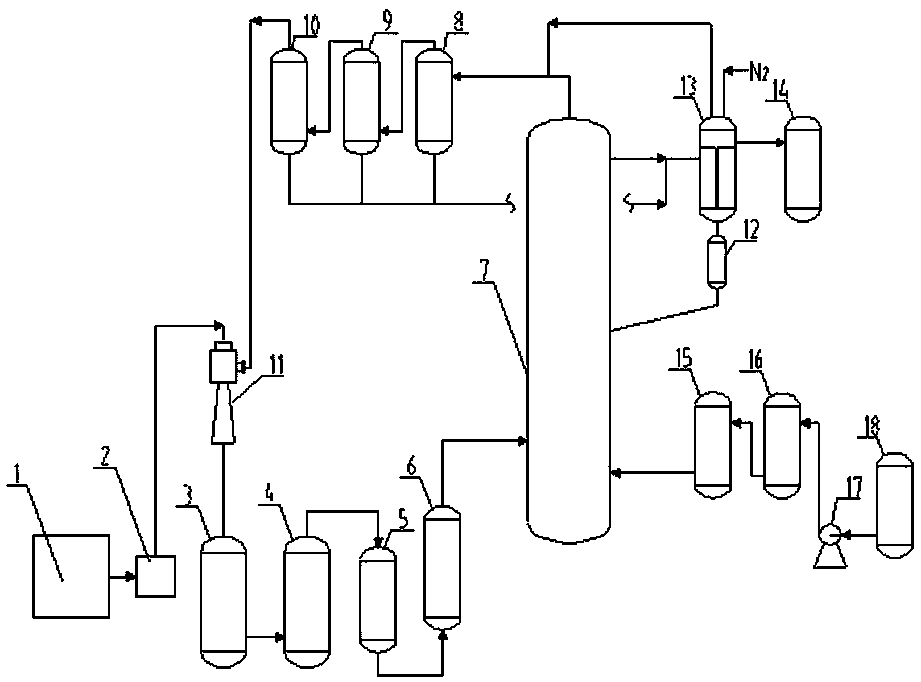

[0047] Embodiment 1 A kind of anthraquinone method prepares hydrogen peroxide fluidized hydrogenation process

[0048] The technical scheme that the present invention adopts: asfigure 1 Shown, a kind of anthraquinone method prepares hydrogen peroxide hydrogenation unit fluidized bed process, comprises the following steps:

[0049] Step 1: Preparation of high-purity hydrogen

[0050] The industrial hydrogen is compressed by the hydrogen compressor 1 to maintain a hydrogen pressure of 0.25Mpa, and deoxygenated by the deoxidizer 2, and the oxygen in the hydrogen reacts with the hydrogen under the action of the palladium catalyst to form water. After removing impurity oxygen, it enters the hydrogen injector 11, Mix with circulating hydrogen, pass through hydrogen cooler 3 and steam-water separator 4, cool and separate to remove free condensed water, and then enter molecular sieve dryer 5 for dehumidification.

[0051] The circulating hydrogen temperature is 15-40°C, and the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com