Electrocatalytic hydrogen production porous high-entropy alloy electrode material and preparation method thereof

A high-entropy alloy and electrode material technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., to achieve the effects of large active specific surface area, environmental friendliness, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. A method for preparing a porous high-entropy alloy electrode material for electrocatalytic hydrogen production, comprising the following steps:

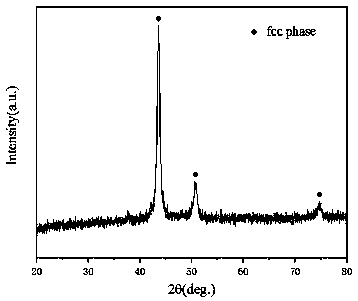

[0033] S1. First mix cobalt powder, chromium powder, iron powder, nickel powder and molybdenum powder with a purity of not less than 99.5% and a particle size between 1 and 100 μm in an atomic ratio of 35:15:20:20:10. The mixed powder is placed in a planetary ball mill, the control speed is 250 r / min, and the ball mill is 6h until uniform; then add magnesium powder and continue ball milling for 2h until uniform, the mass percentage of the magnesium powder is cobalt powder, chromium powder, iron powder, nickel powder 20% of the total mass of powder, molybdenum powder and magnesium powder; finally, use a press to press the above-mentioned mixed powder into a sample billet, the pressure is 650MPa, and the pressure is maintained for 1min;

[0034] S2. Place the sample compacted in step S1 at the central position in the polycrys...

Embodiment 2

[0056] 1. A method for preparing a porous high-entropy alloy electrode material for electrocatalytic hydrogen production, comprising the following steps:

[0057] S1. First mix cobalt powder, chromium powder, iron powder, nickel powder and molybdenum powder with a purity of not less than 99.5% and a particle size between 1 and 100 μm in an atomic ratio of 35:15:20:20:10. The mixed powder is placed in a planetary ball mill, the control speed is 200 r / min, and the ball mill is 7h until uniform; then add magnesium powder and continue ball milling for 3h until uniform, the mass percentage of the magnesium powder is cobalt powder, chromium powder, iron powder, nickel powder 5% of the total mass of powder, molybdenum powder and magnesium powder; finally, use a press to press the above mixed powder into a sample billet, the pressure is 750MPa, and the pressure is maintained for 2min;

[0058] S2. Place the sample compacted in step S1 at the central position in the polycrystalline mul...

Embodiment 3

[0062] 1. A method for preparing a porous high-entropy alloy electrode material for electrocatalytic hydrogen production, comprising the following steps:

[0063] S1. First mix cobalt powder, chromium powder, iron powder, nickel powder and molybdenum powder with a purity of not less than 99.5% and a particle size between 1 and 100 μm in an atomic ratio of 35:15:20:20:10. The mixed powder is placed in a planetary ball mill, the control speed is 300 r / min, and the ball mill is 4h until uniform; then add magnesium powder and continue ball milling for 1.5h to be uniform, the mass percentage of the magnesium powder is cobalt powder, chromium powder, iron powder, 10% of the total mass of nickel powder, molybdenum powder and magnesium powder; finally, the above-mentioned mixed powder is pressed into a sample billet with a press machine, and the pressure is 800MPa, and the pressure is maintained for 3 minutes;

[0064] S2. Place the sample compacted in step S1 at the central position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com