Sepiolite functional non-woven fabric and preparation method and application thereof

A non-woven fabric and functional technology, which is applied in the field of sepiolite functional non-woven fabric and its preparation, can solve the problem of not being able to effectively avoid bacterial reproduction and infection and cross-infection, non-woven fabrics with weak toughness, and restrictions on non-woven fabrics. Use and other problems, to achieve good heat resistance, good moisture absorption performance, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of sepiolite functional non-woven fabric, comprising the following steps:

[0043] S1. The weight part of the support body is made into powder and passed through a 100-150 mesh sieve to prepare a support body solution; the weight part of the nano-silica particles is prepared into a modifier solution, and the two solutions are uniformly mixed; stir and heat up to 30 At ~50°C, keep stirring for 10-40min, then raise the temperature to 55-70°C, add the above-mentioned parts by weight of alum, keep stirring until the solids are completely dissolved, and filter the dissolved solution through a 100-180-mesh filter device;

[0044] S2, soak the fiber non-woven fabric in NaOH solution, take it out, and wash;

[0045] S3. Cool down the solution obtained in S1, add ammonium bicarbonate and the remaining components in the above parts by weight, and stir to obtain a slurry;

[0046] S4. Under ultraviolet light irradiation, coat the slurry obtained in S3 on the fi...

Embodiment 1

[0054] A sepiolite functional nonwoven fabric, in parts by weight, the raw materials for preparing the sepiolite functional nonwoven fabric include: 90 parts of fiber nonwoven fabric, 30 parts of carrier, 1 part of nano silicon dioxide particles part, 1 part of chitosan;

[0055] The carrier includes attapulgite, activated sepiolite fiber, diatomaceous earth and polyester amide compound, and the ratio of parts by weight is: 1:1:1:0.5. The non-woven fabric is made of polyester.

[0056] The preparation method of the activated sepiolite fiber is as follows: according to the solid-liquid ratio of 1:8, the sepiolite fiber is mixed with the inorganic acid solution, the solid-liquid mixture is ultrasonically cleaned, and then irradiated, and the obtained The activated sepiolite fibers were rinsed and then dried.

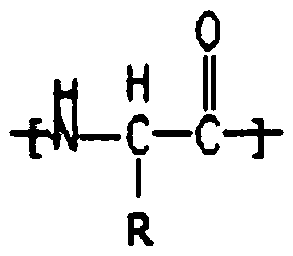

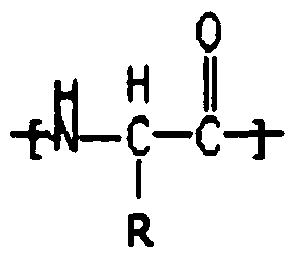

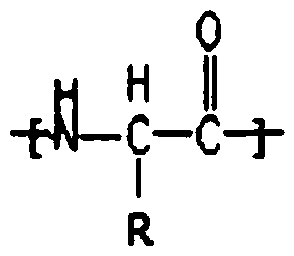

[0057] Described polyester amide compound comprises 5mol% tertiary hydrogen carboxylic acid units, and the remainder is aliphatic carboxylic acid units and aliphatic alc...

Embodiment 2

[0069] A sepiolite functional nonwoven fabric, in parts by weight, the raw materials for preparing the sepiolite functional nonwoven fabric include: 110 parts of fiber nonwoven fabric, 50 parts of carrier, 6 parts of nano silicon dioxide particles 6 parts, chitosan;

[0070] The carrier includes attapulgite, activated sepiolite fiber, diatomaceous earth and polyester amide compound, and the ratio of parts by weight is: 1:3:2:2. The non-woven fabric is made of polyester.

[0071] The preparation method of the activated sepiolite fiber is as follows: according to the ratio of solid to liquid ratio of 1:10, the sepiolite fiber is mixed with the inorganic acid solution, the solid-liquid mixture is ultrasonically cleaned, and then irradiated, and the obtained The activated sepiolite fibers were rinsed and then dried.

[0072] Described polyester amide compound comprises 38mol% tertiary hydrogen carboxylic acid unit, the remainder is aliphatic carboxylic acid unit and aliphatic al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com