Perovskite nanocrystalline with alkali metal ion passivated surface defects as well as preparation and application of perovskite nanocrystalline

An alkali metal ion, perovskite technology, applied in nanotechnology, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as hindering the charge transport of NCs light-emitting diodes, high dynamic instability, affecting LED performance, etc. The effect of improving electrical transport performance, device brightness and external quantum efficiency, and reducing organic ligand density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

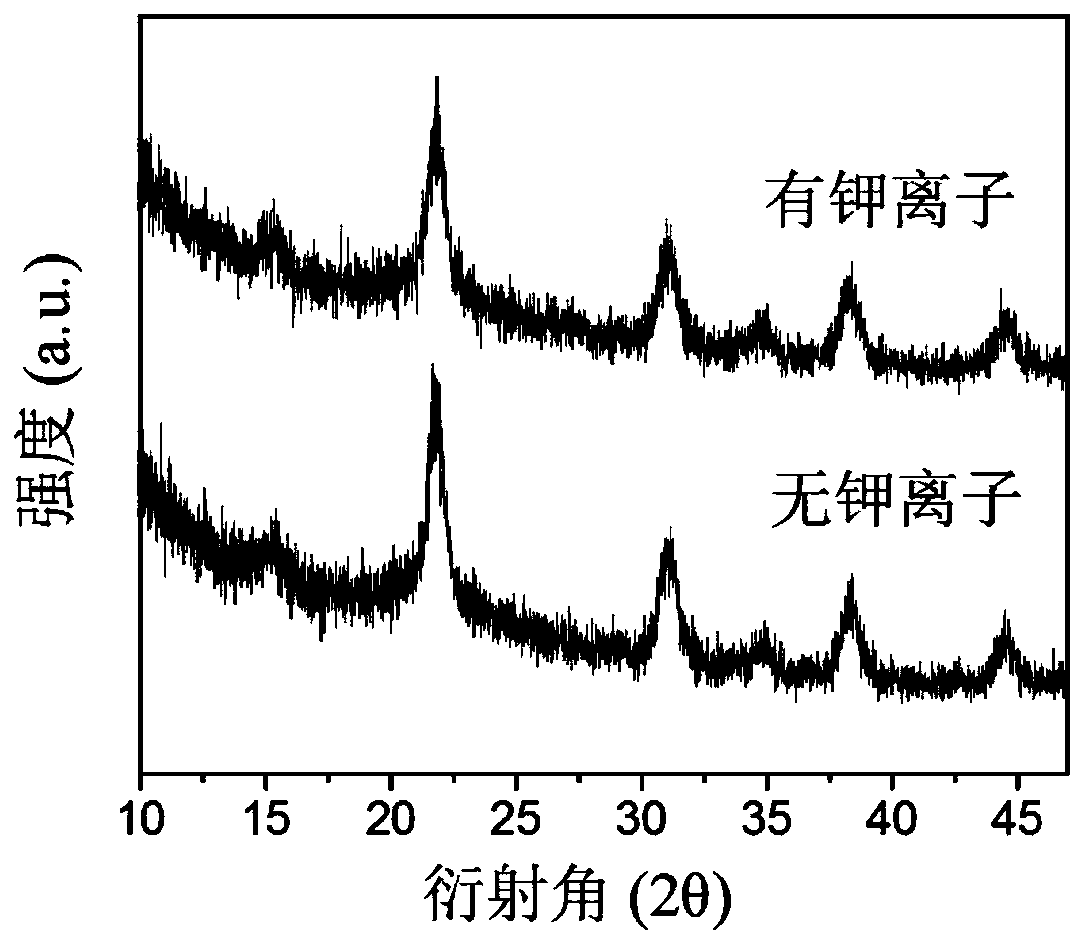

[0049] Generally speaking, the preparation method of the perovskite nanocrystal of alkali metal ion passivation surface defect in the present invention comprises the following steps: the ligand solution of alkali metal ion and the ligand solution of monovalent cation are mixed, fast (time is not More than 2s) into the stirred poor solution of divalent metal halides with quaternary ammonium salts as solubilizers. After the perovskite is formed, add the poor solution of organic ligands to the mixed solution to obtain perovskite nanocrystals. liquid, purifying the perovskite nanocrystal crude liquid to obtain a colloidal solution of perovskite nanocrystals in which surface defects are passivated by alkali metal ions;

[0050] Wherein, the halogen element in the halide is one or more of F, Cl, Br, I;

[0051] Alkali metal ions are selected from Li + 、Na + 、K + , Rb + One or more of them are derived from alkali metal inorganic salts.

[0052] In some embodiments, when the alka...

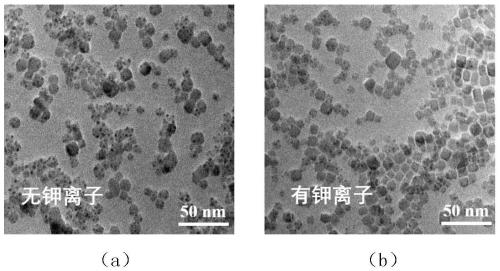

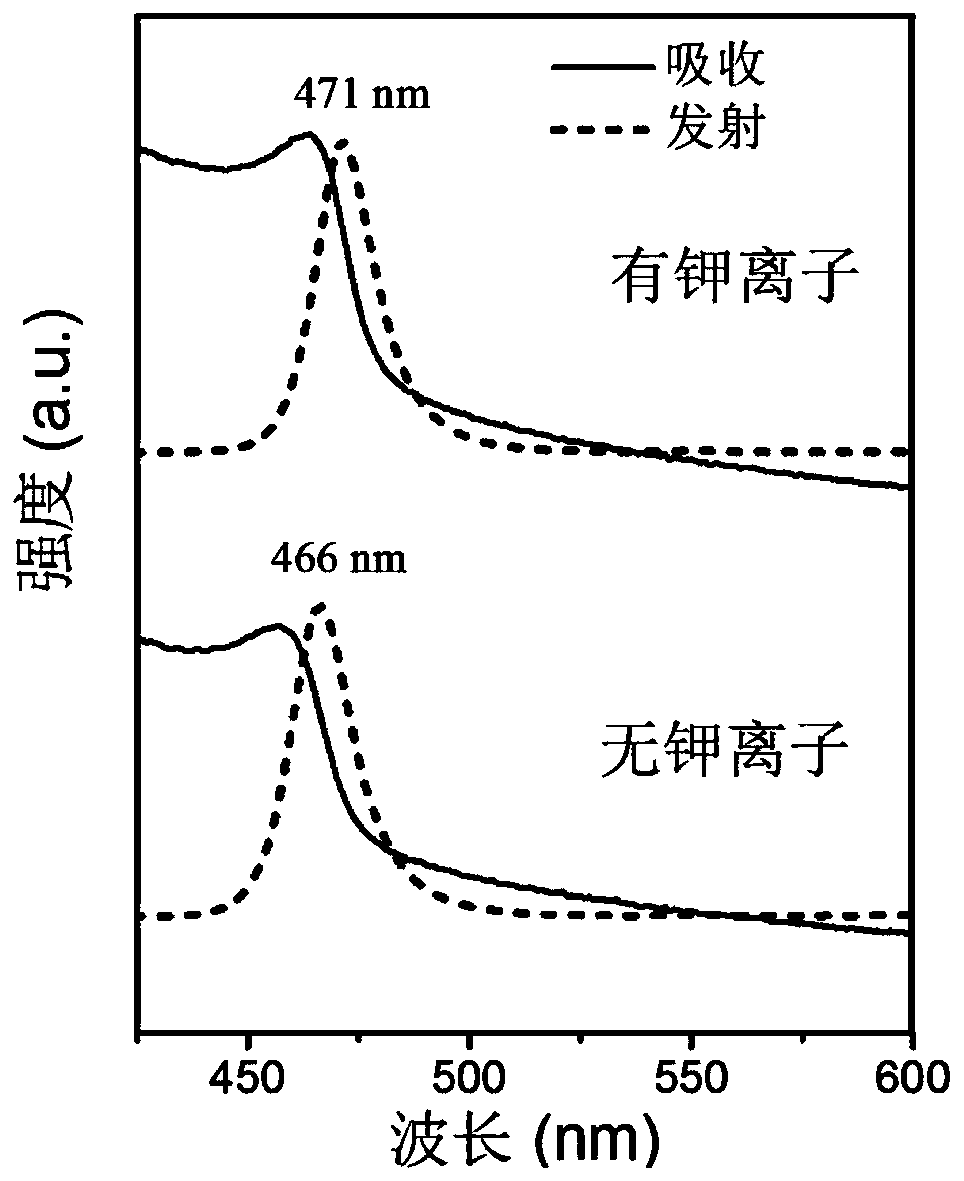

Embodiment 1

[0081] This embodiment provides a method for preparing perovskite nanocrystals with potassium ions passivating surface defects, and applying the nanocrystals prepared by this method to light-emitting diodes, which specifically includes the following steps:

[0082] 1. CsPb(Br / Cl) 3 Preparation of NCs solution: accurate weighing of PbBr with electronic balance 2 (0.125mmol, 0.046g), PbCl 2 (0.125mmol, 0.035g) and tetra-n-octylammonium bromide (0.750mmol, 0.410mg), add 5mL of toluene as a solvent, and stir on a magnetic stirrer until the raw materials are fully dissolved. Prepare Cs with a concentration of 0.1mol / L respectively 2 CO 3 The octanoic acid solution with a concentration of 0.1mol / L of K 2 CO 3 octanoic acid solution. Pipette 300 μL of Cs 2 CO 3 octanoic acid solution, 50 μL K 2 CO 3 The octanoic acid solution and 305 μL octanoic acid solution were thoroughly mixed in a bullet plastic tube. The mixed solution in the bullet plastic tube was quickly dropped ...

Embodiment 2

[0100] Compared with Example 1, embodiment 2 is only different in step 1 (that is, the preparation of NCs solution), and step 2 (that is, the preparation of light-emitting diodes) only needs to use the NCs solution obtained in corresponding step 1. In step 2, The overall technological process sequence, the setting of specific parameter conditions, etc. are all the same as in Example 1. Step 1 is as follows:

[0101] CbBr 3 Preparation of NCs solution: accurate weighing of PbBr with electronic balance 2 (0.250mmol, 0.092g) and tetra-n-octylammonium bromide (0.750mmol, 0.410mg), add 5mL of toluene as a solvent, and stir on a magnetic stirrer until the raw materials are fully dissolved. Prepare Cs with a concentration of 0.1mol / L respectively 2 CO 3 The octanoic acid solution with a concentration of 0.1mol / L of K 2 CO 3 octanoic acid solution. Pipette 300 μL of Cs 2 CO 3 octanoic acid solution, 50 μL K 2 CO 3 The octanoic acid solution and 305 μL octanoic acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com