Quaternary ammonium salt polymer and preparation method and application thereof

A technology of quaternary ammonium salts and polymers, which is applied in the field of quaternary ammonium salts polymers and their preparation, and can solve the problems of bacteria breeding in processing fluids, odor corruption of processing fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

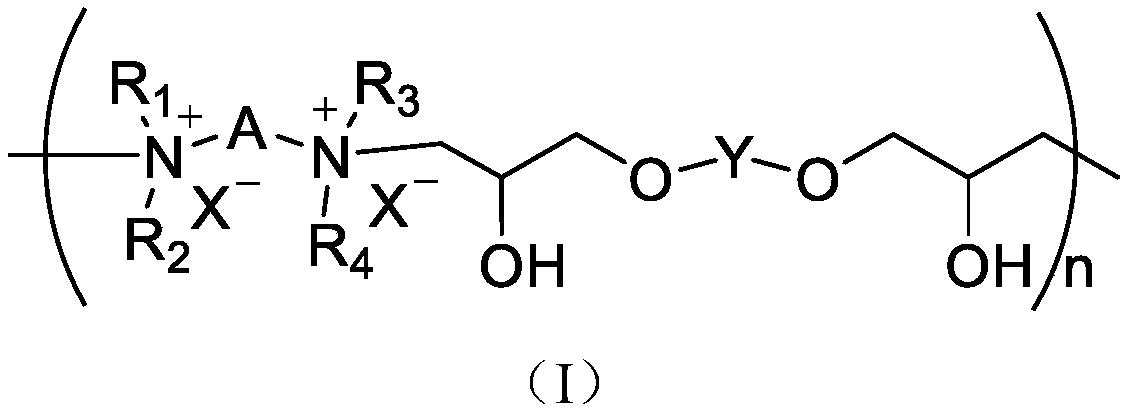

Method used

Image

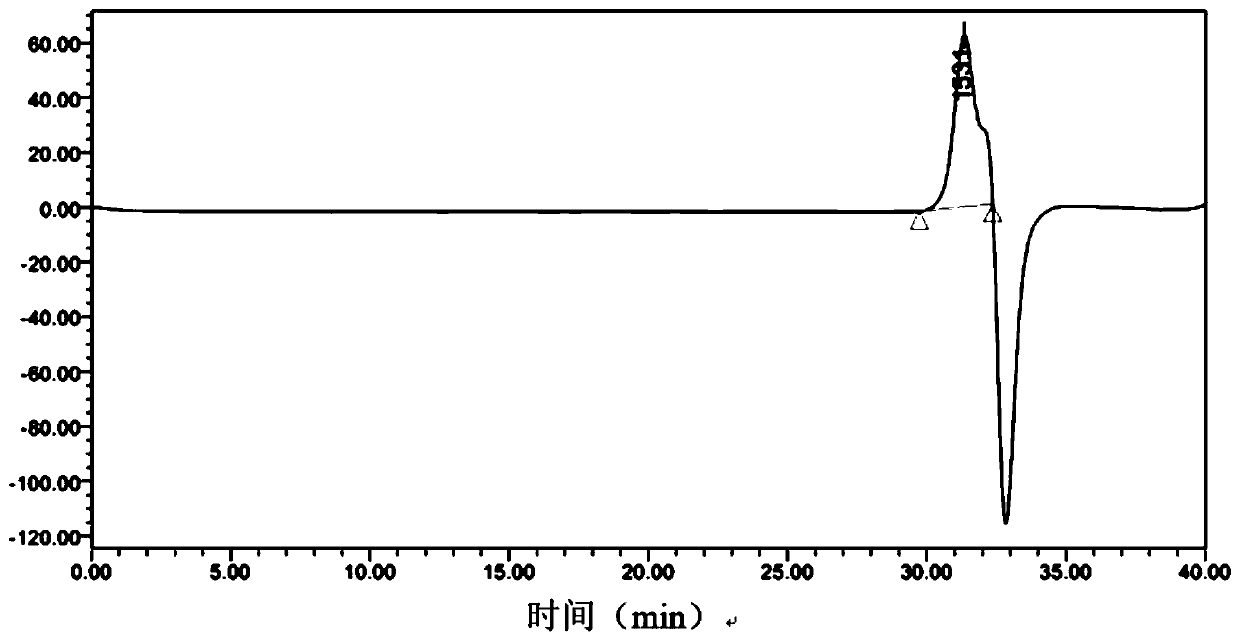

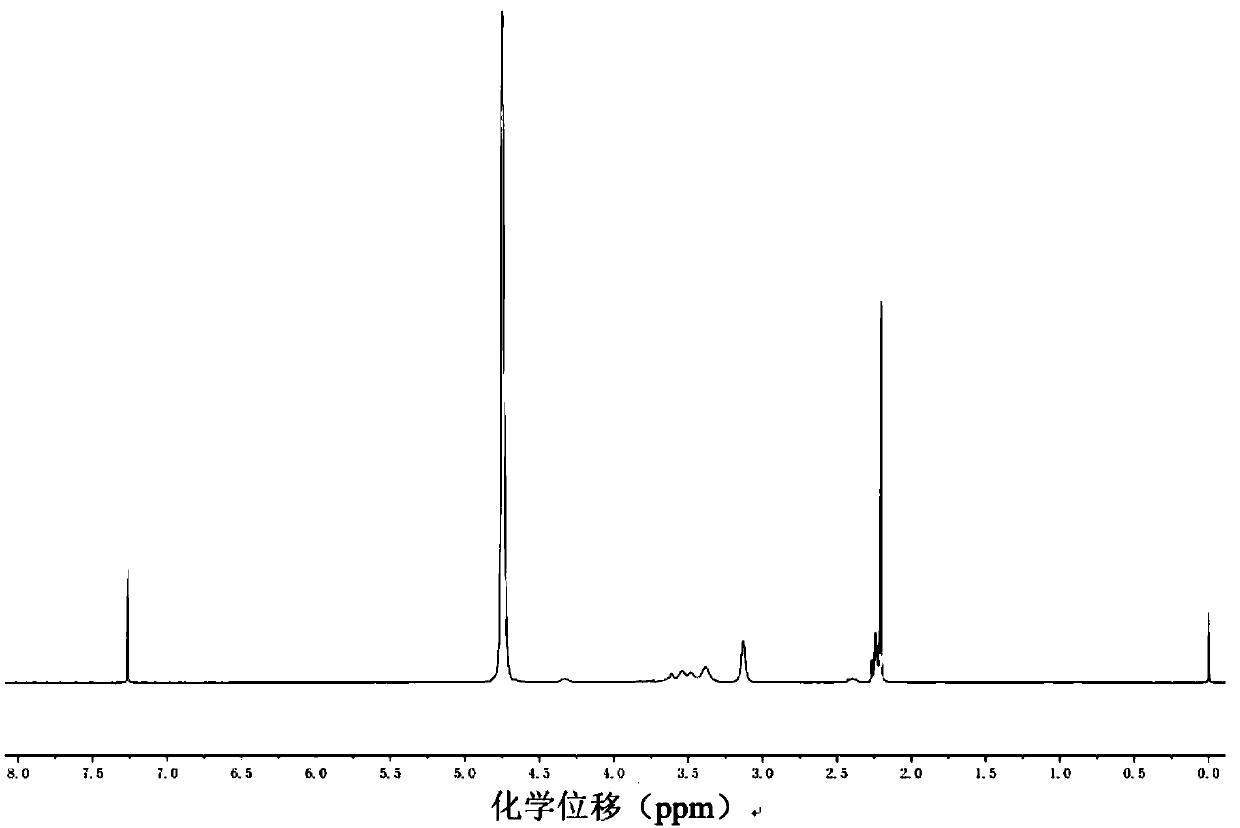

Examples

Embodiment 1

[0062] Add 30.0g of ethylene glycol into a three-necked flask, dehydrate at 80°C for 60min, add 0.07g of boron trifluoride ether, and cool down to 70°C, slowly add 89.4g of epichlorohydrin into the flask drop by drop, and after the addition is complete, After oxychloropropane, the reaction was continued at 70°C for 1 hour, and then degassed under reduced pressure for 15 minutes. The solution was cooled to room temperature, and 103.0 g of 50% KOH aqueous solution was slowly added drop by drop. After the addition was completed, it was heated to 40° C. for about 2 hours, and the pH was measured to be 6.5. Afterwards, the temperature was raised to 80°C, and 0.17g of polyether refined preparation (magnesium silicate, CAS: 1343-88-0) was added, kept at 80°C for 1 hour, vacuum degassed until the water content of the solution was less than 0.1%, and filtered under reduced pressure to obtain 79.1g of the filtrate is ethylene glycol diglycidyl ether.

[0063] Add 105.0 g of tetramethyl...

Embodiment 2

[0069] Add 30.0g of butanediol into the three-necked flask, dehydrate at 80°C for 60min, add 0.09g of boron trifluoride ether, and lower the temperature to 60°C, slowly add 92.4g of epichlorohydrin into the flask drop by drop, and the epoxy After chloropropane, the reaction was continued at 60°C for 1 hour, and then degassed under reduced pressure for 15 minutes. The solution was cooled to room temperature, and 104.6 g of 50% KOH aqueous solution was slowly added dropwise. After the addition was completed, it was heated to 40° C. for about 2 hours, and the pH was measured to be 6.0. After that, the temperature was raised to 80°C, and 0.49g of polyether refined preparation (magnesium silicate) was added, kept at 80°C for 1 hour, vacuum degassed until the water content of the solution was less than 0.1%, and filtered under reduced pressure to obtain 96.1g of filtrate, which was butanediol Alcohol diglycidyl ether.

[0070] Add 100.0 g of tetraethylethylenediamine into the three...

Embodiment 3

[0076] Add 40.0g of PEG-200 into a three-necked flask, dehydrate at 90°C for 60min, add 1.13g of boron trifluoride ether, and lower the temperature to 70°C, slowly add 74.0g of epichlorohydrin into the flask drop by drop. After oxychloropropane, the reaction was continued at 70°C for 1 hour, and then degassed under reduced pressure for 15 minutes. The solution was cooled to room temperature, and 83.0 g of 50% KOH aqueous solution was slowly added drop by drop. After the addition was completed, it was heated to 40° C. for about 2 hours, and the pH was measured to be 5.7. Afterwards, the temperature was raised to 80°C, and 0.99g of polyether refined preparation (magnesium silicate) was added, kept at 80°C for 1 hour, vacuum degassed until the water content of the solution was less than 0.1%, and filtered under reduced pressure to obtain 97.0g of filtrate, which was polyethylene Diol diglycidyl ether.

[0077] Add 38.0 g of tetramethylpropylenediamine into the three-necked flask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com