Method for preparing ZnO/TiO2 heterojunction thin-film material through spin-coating

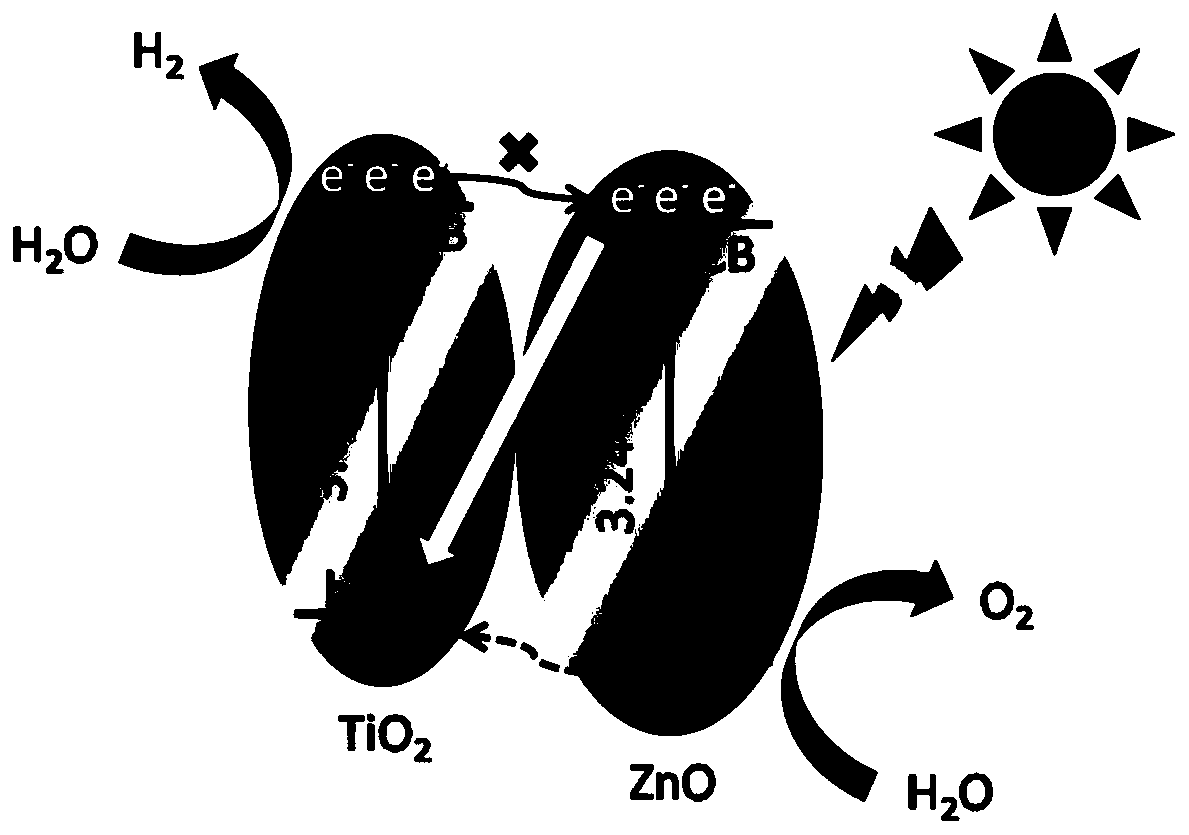

A thin-film material and heterojunction technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor light absorption, photoelectric catalytic activity and stability, Small specific surface area and other issues to achieve the effect of improving stability and weakening light corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

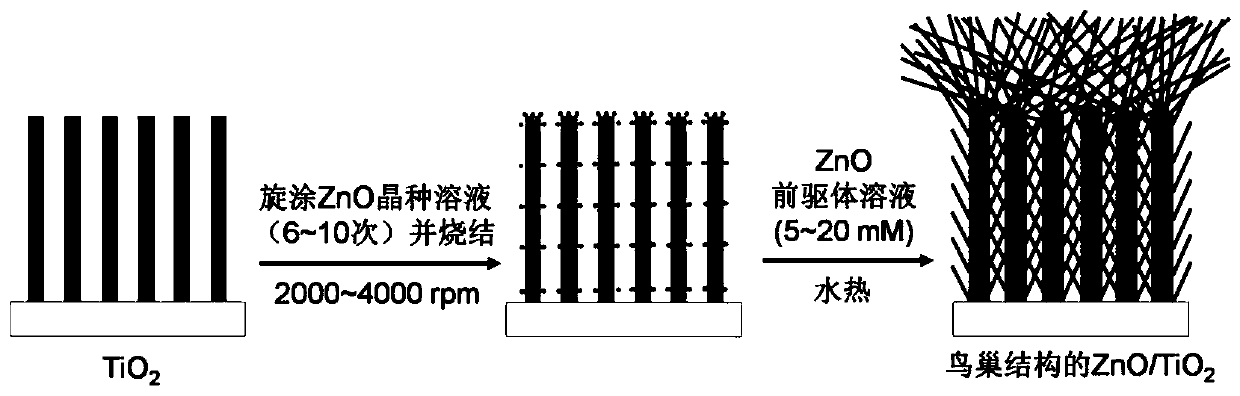

[0028] This embodiment specifically includes the following steps:

[0029] ① Preparation of TiO by hydrothermal method 2 Nanorod film: add 0.6mL tetrabutyl titanate to 30mL 1:1 aqueous solution of concentrated hydrochloric acid, stir rapidly for 2 hours to obtain a transparent solution; place the conductive glass in a hydrothermal kettle filled with the above tetrabutyl titanate solution 150°C for 12 hours, cooled, washed with water, dried, heated to 450°C at a rate of 1°C / min in a muffle furnace, and kept for 1 hour to obtain TiO 2 nanorod films.

[0030] ②In the prepared TiO 2 Spin-coat 10mM zinc acetate-ethanol solution on the nanorod film to prepare ZnO seeds; the spin-coating speed is 3000rpm, and the number of spin-coating is 8 times. After each spin-coating, place it on a hot plate at 150°C for heating 2min, then take it off, cool to room temperature, and do the next spin coating.

[0031] ③ After the spin coating is completed, place it on a hot plate at 450 ° C for...

Embodiment 2

[0051] Prepare TiO according to Example 1 2 Nanorod films, prepared TiO 2 Spin-coat 10mM zinc acetate-ethanol solution on the nanorod film to prepare ZnO seeds; the spin-coating speed is 2000rpm, and the number of spin-coating is 6 times. After each spin-coating, place it on a hot plate at 150°C for heating 2min, then take it off, cool to room temperature, perform the next spin coating until the spin coating is completed, place it on a hot plate at 450°C and heat it for 1h. 2 ZnO nanowires were grown on the surface of the nanorod film; subsequently, TiO with a ZnO seed layer 2 The film was placed in a mixed solution of 20mM zinc nitrate and hexamethylenetetramine, heated in an oven at 90°C for 4h to grow ZnO nanowires, then taken out and rinsed with deionized water several times, and then dried at 50°C for 1h. ZnO / TiO with bird's nest structure 2 Heterojunction thin film electrodes.

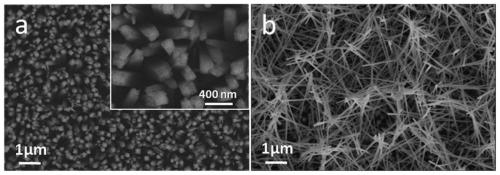

[0052] The ZnO / TiO of the bird's nest structure that this embodiment prepares 2 film in ...

Embodiment 3

[0054] Prepare TiO according to Example 1 2 Nanorod films, prepared TiO 2 Spin-coat 10mM zinc acetate-ethanol solution on the nanorod film to prepare ZnO seeds; the spin-coating speed is 4000rpm, and the number of spin-coating is 10 times. After each spin-coating, place it on a hot plate at 150°C for heating 2min, then take it off, cool to room temperature, and perform the next spin coating until the spin coating is completed, place it on a hot plate at 450°C and heat it for 1h. 2 ZnO nanowires were grown on the surface of the nanorod film; subsequently, TiO with a ZnO seed layer 2 The film was placed in a mixed solution of 5mM zinc nitrate and hexamethylenetetramine, heated in an oven at 90°C for 4h to grow ZnO nanowires, then taken out and rinsed with deionized water several times, and then dried at 50°C for 1h. ZnO / TiO with bird's nest structure on the surface 2 Heterojunction thin film electrodes.

[0055] The ZnO / TiO of the bird's nest structure that this embodiment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com