Efficient low-temperature closed crawler-type sludge drying machine and working method thereof

A sludge drying and crawler-type technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the difficult treatment of tail gas, secondary sludge, consumption of large petrochemical energy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

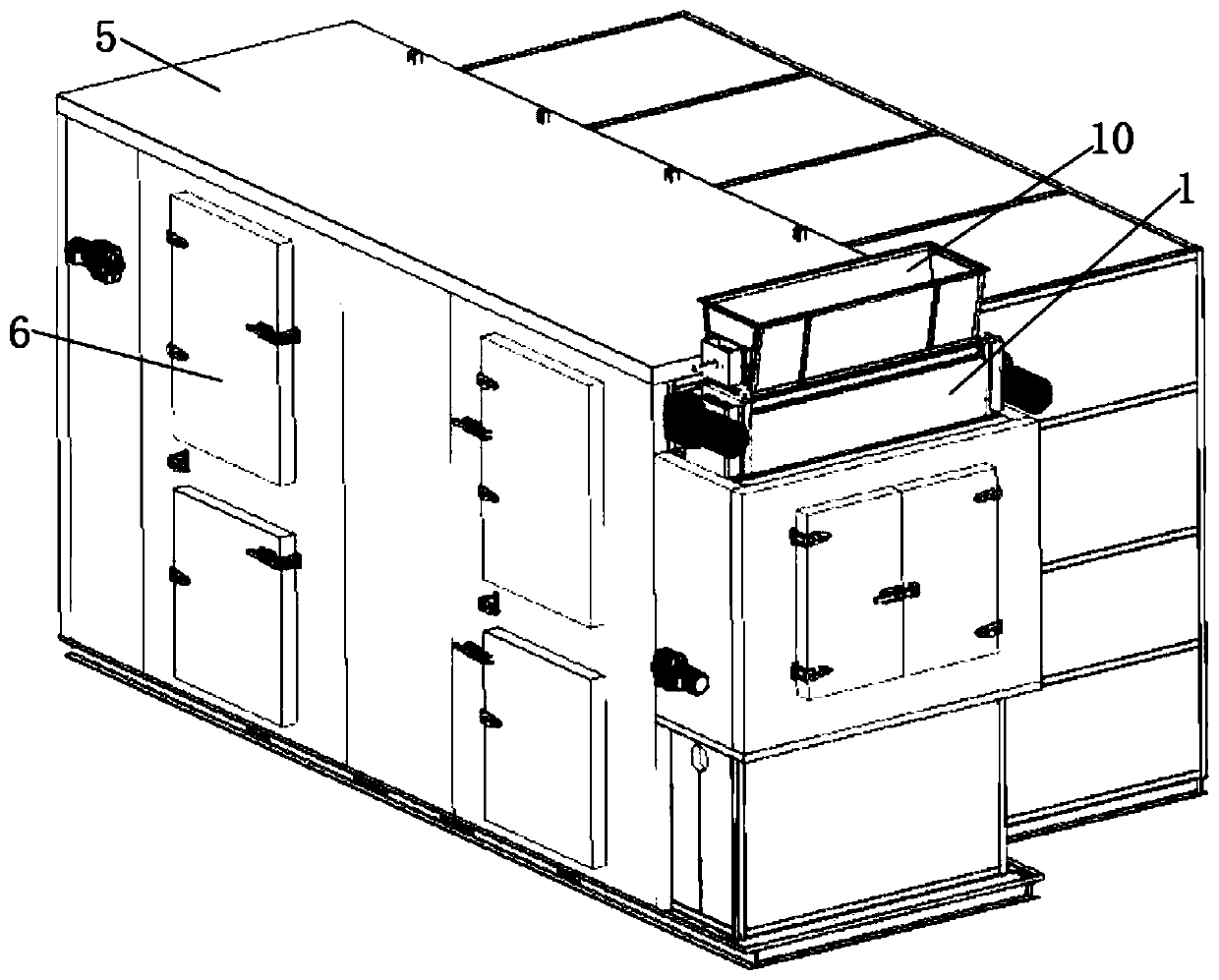

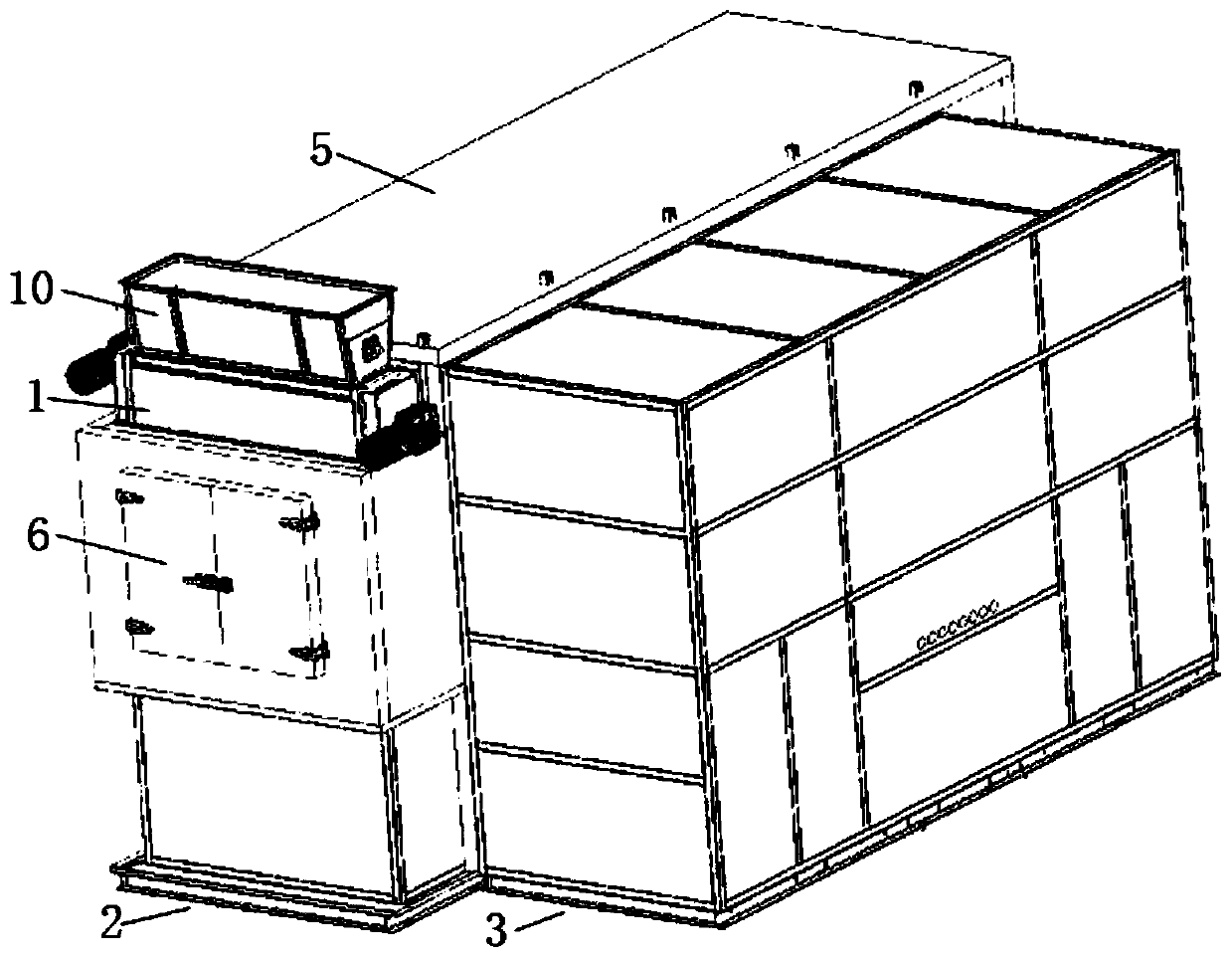

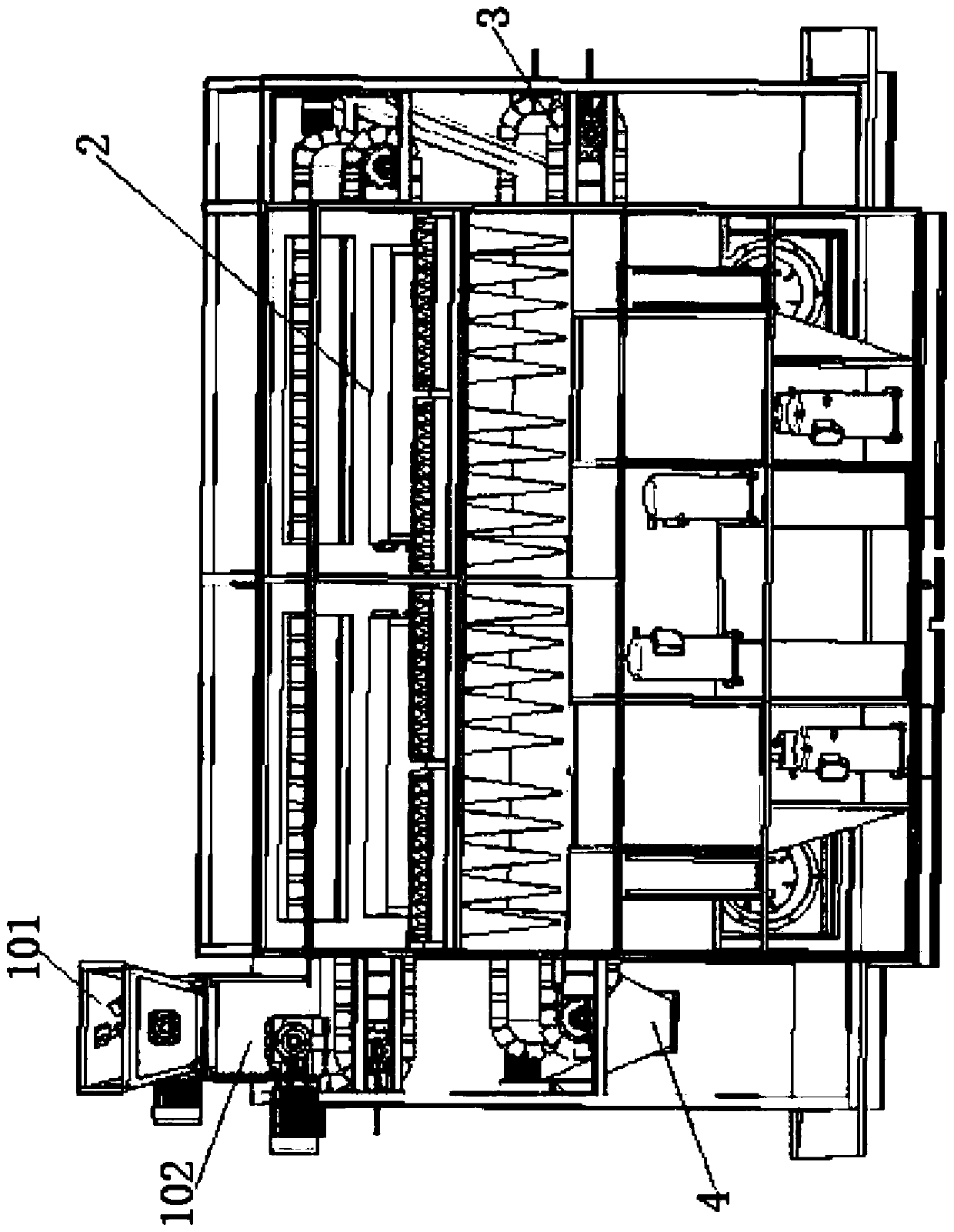

[0051] Such as figure 1 , 2 The shown high-efficiency low-temperature airtight crawler sludge dryer includes a storage bin 10, a cutting pelletizing mechanism 1, a heat pump mechanism 2, a mesh belt conveying mechanism 3, a discharging mechanism 4, an external sealed box body 5, and a set The box door 6, the set of box doors 6 is arranged on the outer sealed box body 5, the cutting and granulating mechanism 1 is arranged on the upper end of the outer sealed box 5, and the cutting and granulating mechanism 1 is located on the outer sealed box. On one side of the box body 5, the storage bin 10 is arranged on the cutting and granulating mechanism 1. The cutting and granulating mechanism 1 is located directly above the side of the mesh belt conveying mechanism 3. The heat pump mechanism 2, the mesh The belt conveying mechanism 3 and the discharging mechanism 4 are both arranged in the external sealed box 5. The discharging mechanism 4 is located at the end of the mesh belt conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com