Method for preparing p-tert-butylphenol by using MTBE as raw material

A technology for p-tert-butylphenol and raw materials, which is applied in the field of preparing p-tert-butylphenol, can solve the problems of low MTBE conversion rate, strong catalyst corrosion, harsh reaction conditions, etc., and achieves high conversion rate, stable catalyst activity, and process flow. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

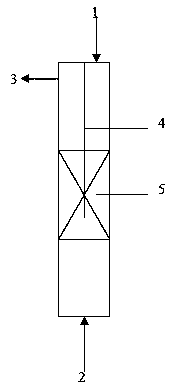

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 30% ZrOCl 2 Ethanol solution, titrated with 20% ammonia water until there is no white precipitate, washed 5 times with deionized water, 10 minutes each time, washing temperature is 40 ° C, washed to no chloride ion, and then placed in vacuum drying at 90 ° C Dry in an oven for 6 hours, extrude and then bake at 500°C for 8 hours to obtain white solid particles for use. b: The obtained white solid particles are packed into a steel mesh bag, laid flat in an ultrasonic vibrator with a thickness of 2 mm, and the silver nitrate sulfuric acid solution and nitrogen with a molar concentration of 3 mol / L and nitrogen are subjected to ultrasonic vibration with an atomizing nozzle. Spray solid particles down, the spray distance is 1.5cm, the spray pressure is 0.08MPa, and the spray time is 2h. After drying and roasting, the particles I are obtained. The drying...

Embodiment 2

[0045] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 35% ZrOCl 2 Ethanol solution, titrated with 20% ammonia water until there is no white precipitate, washed 5 times with deionized water, 10 minutes each time, washing temperature is 40 ° C, washed to no chloride ion, and then placed in vacuum drying at 90 ° C Dry in an oven for 6 hours, extrude, and then bake at 450°C for 8 hours to obtain white solid particles for use. b: The obtained white solid particles are packed into a wire mesh bag, laid flat in an ultrasonic vibrator with a thickness of 2mm, and the silver nitrate sulfuric acid solution and nitrogen with a molar concentration of 4mol / L and nitrogen are subjected to ultrasonic vibration with an atomizing nozzle Spray solid particles down, the spray distance is 1.5cm, the spray pressure is 0.07MPa, and the spray time is 2h. After drying and roasting, the particles I are obtained. The drying te...

Embodiment 3

[0048] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 40% ZrOCl 2 Ethanol solution, titrated with 20% ammonia water until there is no white precipitate, washed 5 times with deionized water, 10 minutes each time, washing temperature is 40 ° C, washed to no chloride ion, and then placed in vacuum drying at 90 ° C Dry in an oven for 6 hours, extrude and then bake at 500°C for 8 hours to obtain white solid particles for use. b: Pack the obtained white solid particles into a wire mesh bag, spread them flat in an ultrasonic vibrator with a thickness of 2 mm, and use an atomizing nozzle to mix a silver nitrate sulfuric acid solution with a molar concentration of 2 mol / L and nitrogen under the conditions of ultrasonic vibration Spray solid particles down, the spray distance is 1.5cm, the spray pressure is 0.06MPa, and the spray time is 2h. After drying and roasting, the particles I are obtained. The drying te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com