A kind of method and integrated device for refining dimethyl carbonate

A dimethyl carbonate and integrated device technology, which is applied in the field of industrialized production of dimethyl carbonate, can solve problems such as high energy consumption, unstable device operation, and difficult operation, so as to reduce energy consumption, save production costs, reduce Effect of methanol and water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

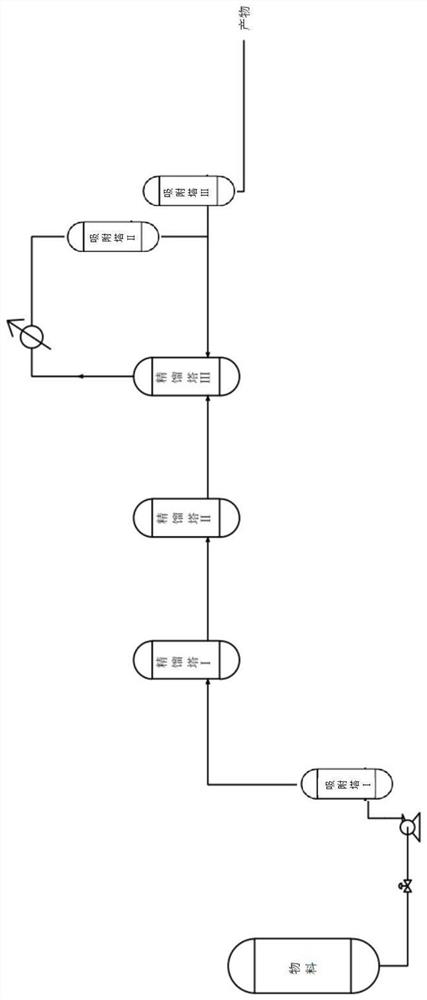

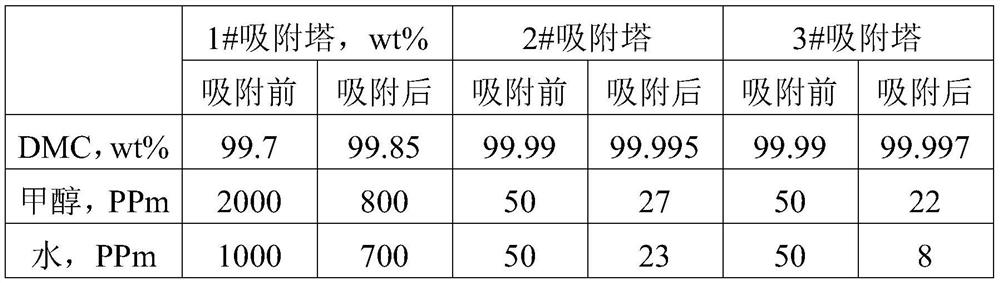

[0063] The dimethyl carbonate material with a concentration of 99.7% is successively fed into figure 1 The integrated device shown, wherein the proportions of the composite adsorbents in each adsorption tower are as follows;

[0064] (1) Continuous rectification feed position adsorption tower (1# adsorption tower), the amount of cationic resin in the composite adsorbent is 60%, and the amount of porous molecular sieve is 40%;

[0065] (2) The adsorption tower at the top of the low-pressure rectification tower (2# adsorption tower), the amount of cationic resin in the composite adsorbent is 10%, and the amount of porous molecular sieve is 90%;

[0066] (3) The adsorption tower (3# adsorption tower) in the product extraction position, the composite adsorbent porous molecular sieve dosage is 50%, and the aluminum oxide dosage is 50%.

[0067] Table 1 shows the DMC purity and methanol and water content data of the materials treated by the 1# adsorption tower, the 2# adsorption to...

Embodiment 2

[0071] The dimethyl carbonate material with a concentration of 99.7% is successively fed into figure 1 The integrated device shown, wherein the proportions of the composite adsorbents in each adsorption tower are as follows;

[0072] (1) Continuous rectification feed position adsorption tower (1# adsorption tower), the amount of cationic resin in the composite adsorbent is 80%, and the amount of porous molecular sieve is 20%;

[0073] (2) The adsorption tower at the top of the low-pressure rectification tower (2# adsorption tower), the amount of cationic resin in the composite adsorbent is 10%, and the amount of porous molecular sieve is 90%;

[0074] (3) The adsorption tower (3# adsorption tower) in the product extraction position, the composite adsorbent porous molecular sieve dosage is 50%, and the aluminum oxide dosage is 50%.

[0075] Table 2 shows the DMC purity and methanol and water content data after the materials are processed by 1# adsorption tower, 2# adsorption t...

Embodiment 3

[0079] The dimethyl carbonate material with a concentration of 99.7% is successively fed into figure 1 The integrated device shown, wherein the proportions of the composite adsorbents in each adsorption tower are as follows;

[0080] (1) Continuous rectification feed position adsorption tower (1# adsorption tower), the amount of cationic resin in the composite adsorbent is 50%, and the amount of porous molecular sieve is 50%;

[0081] (2) The adsorption tower at the top of the low-pressure rectification tower (2# adsorption tower), the amount of cationic resin in the composite adsorbent is 10%, and the amount of porous molecular sieve is 90%;

[0082] (3) The adsorption tower (3# adsorption tower) in the product extraction position, the composite adsorbent porous molecular sieve dosage is 50%, and the aluminum oxide dosage is 50%.

[0083] Table 3 shows the DMC purity and methanol and water content data after the materials are processed by the 1# adsorption tower, the 2# adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com