Product separation and byproduct utilization method and product separation and byproduct utilization device for preparing olefin from synthesis gas

A synthesis gas and product technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, distillation purification/separation, etc., can solve the problems of by-product utilization, low conversion rate, carbon monoxide removal and low efficiency of hydrogen equipment, and achieve The effect of increasing the benefit of the unit, increasing the yield of diene products, and reducing the unit consumption of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

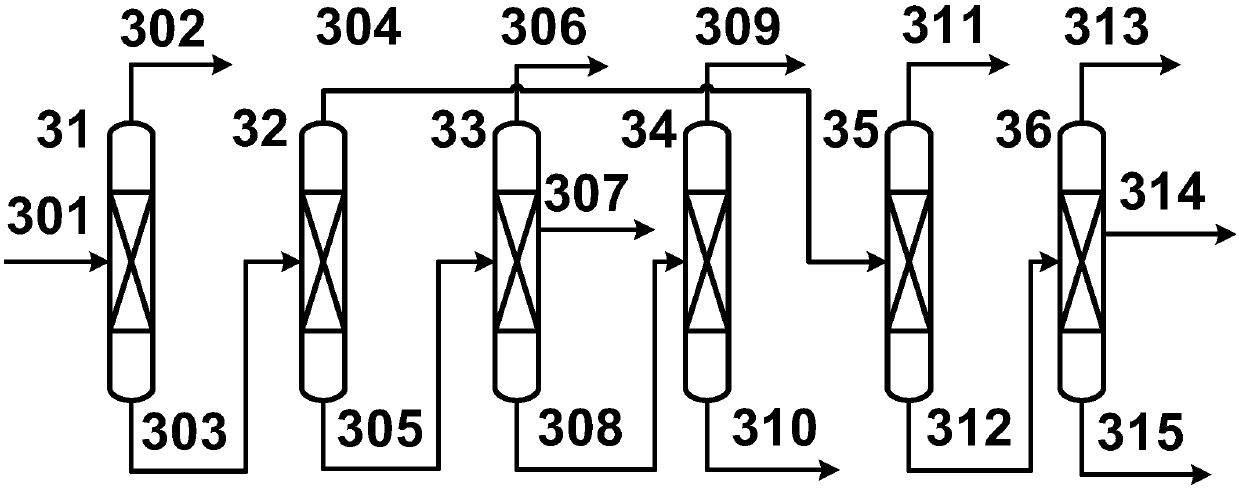

[0183] The product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.40% hydrogen, 46.40% carbon monoxide, 15.70% mixed hydrocarbons, using figure 2 In the technical scheme, methyldiethanolamine is used as an absorbent in the decarbonization zone, pressure swing adsorption separation method is used in the dehydrogenation zone, 76% of the recycle stream is returned to the synthesis gas preparation olefin reactor, and ethylene products and propylene products are obtained by separation.

[0184] The temperature of the low-temperature mixed hydrocarbon stream is minus 105°C and the pressure is 3.5MPaG.

[0185] The carbon dioxide removal rate is 98.64%, the carbon monoxide recovery rate is 98.98%, the hydrogen recovery rate is 98.18%, the ethylene product yield is 2.63% higher than the comparative technical solution, the recovery rate is 97.3%, and the propylene product yield is 2.68% higher than the comparative technical solution , the recovery rate is 99.8...

Embodiment 2

[0187] The product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.40% hydrogen, 46.40% carbon monoxide, 15.70% mixed hydrocarbons, using figure 2 In the technical scheme, methyldiethanolamine is used as an absorbent in the decarbonization zone, pressure swing adsorption separation method is used in the dehydrogenation zone, 86% of the recycle stream is returned to the synthesis gas preparation olefin reactor, and ethylene products and propylene products are obtained by separation.

[0188] The temperature of the low-temperature mixed hydrocarbon stream is minus 110°C and the pressure is 3.4MPaG.

[0189] The carbon dioxide removal rate is 98.63%, the carbon monoxide recovery rate is 98.97%, the hydrogen recovery rate is 98.17%, the ethylene product yield is 2.97% higher than the comparative technical solution, the recovery rate is 97.4%, and the propylene product yield is 3.03% higher than the comparative technical solution , the recovery rate is 99.8...

Embodiment 3

[0191] The product stream obtained in the reaction zone contains: 25.00% carbon dioxide, 3.40% hydrogen, 46.40% carbon monoxide, 15.70% mixed hydrocarbons, using figure 2 In the technical scheme, methyldiethanolamine is used as an absorbent in the decarbonization zone, pressure swing adsorption separation method is used in the dehydrogenation zone, 96% of the recycle stream is returned to the synthesis gas preparation olefin reactor, and ethylene products and propylene products are obtained by separation.

[0192] The temperature of the low-temperature mixed hydrocarbon stream is minus 115°C and the pressure is 3.3MPaG.

[0193] The carbon dioxide removal rate is 98.62%, the carbon monoxide recovery rate is 98.96%, the hydrogen recovery rate is 98.16%, the ethylene product yield is 3.32% higher than the comparative technical solution, the recovery rate is 97.5%, and the propylene product yield is 3.38% higher than the comparative technical solution , the recovery rate is 99.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com