Preparation method of lithium bis(oxalato)borate

A technology of bisoxalate lithium borate and anhydrous oxalic acid, applied in chemical instruments and methods, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc., can solve problems such as high energy consumption, high cost, and difficult purification , to achieve the effect of high energy consumption, high solution cost and high difficulty in purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

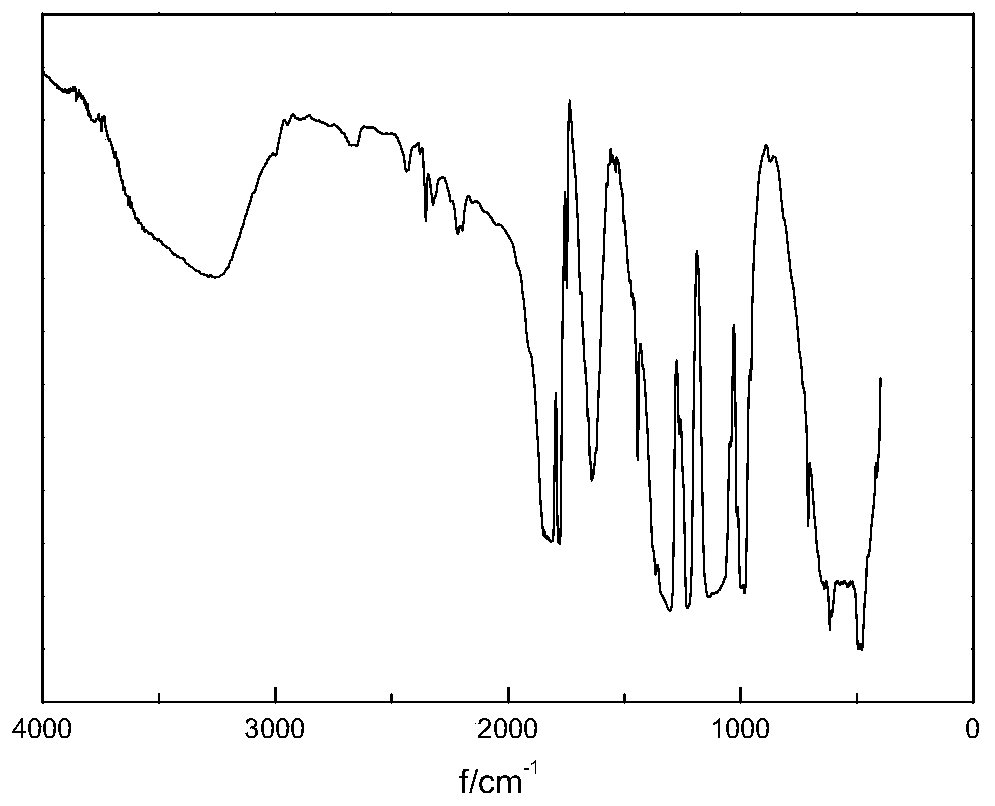

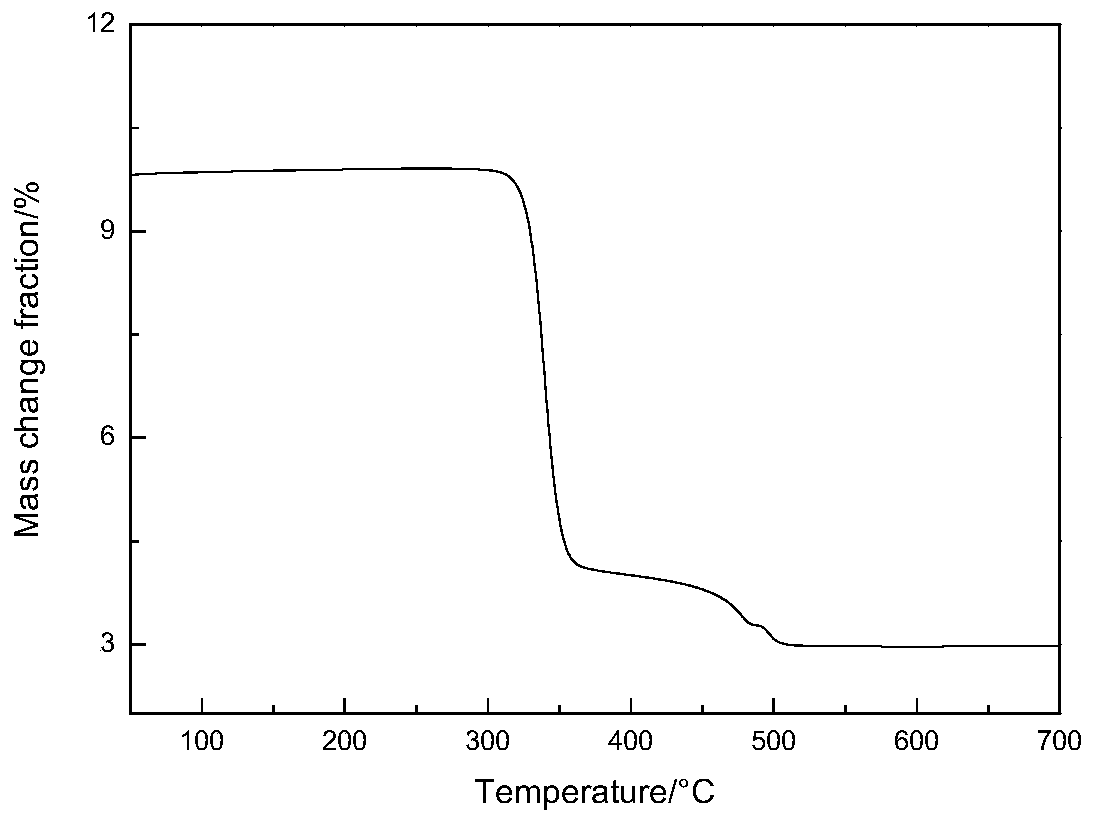

Image

Examples

preparation example Construction

[0046] The invention discloses a method for preparing lithium bisoxalate borate, which mainly includes synthesizing a crude product of lithium bisoxalate borate and concentrating, crystallizing and purifying, specifically including the following steps:

[0047] (1) Take boron simple substance, lithium powder and anhydrous oxalic acid and mix uniformly to obtain mixed raw materials;

[0048] (2) Put the mixed raw material in step (1) into a ball mill and react under normal pressure for 2-6 hours to obtain the product, then add an organic solvent for wet grinding to obtain a solution containing the crude lithium bisoxalate borate;

[0049] (3) Concentrating, crystallizing, filtering, and drying the solution containing the crude lithium bisoxalate borate obtained in step (2) to obtain a lithium bisoxalate borate.

[0050] (1) In order to further realize the technical effect of the present invention, in the mixed raw material of step (1), the molar ratio of boron simple substance,...

Embodiment 1

[0059] At room temperature, add 1.79g lithium powder, 46.46g anhydrous oxalic acid, 2.79g boron powder, reacted at 80°C for 4 hours, cooled to room temperature, slowly added 150g of ethylene glycol dimethyl ether through the solvent inlet, and stirred for 12 hours to completely dissolve the product in the solvent to obtain a solution containing the crude bisoxalate lithium borate .

[0060] Transfer the solution containing the crude lithium bisoxalate borate to a concentration kettle, and concentrate the solution to 80% of the original volume by heating, after cooling it to room temperature, add 150g of dichloromethane for crystallization, and filter to obtain the The wet product of the solvent, which was transferred to the lithium bisoxalate borate product of the organic solvent was dried in a 316L stainless steel drier to obtain the lithium bisoxalate borate product.

[0061] The quality of the obtained lithium bisoxalate borate after drying was 48.24g, the purity of the ob...

Embodiment 2

[0065] At room temperature, add 1.79g lithium powder, 46.46g anhydrous oxalic acid, 2.79g boron Powder, reacted at 80°C for 4 hours, cooled to room temperature, slowly added 150g of ether through the solvent inlet, stirred for 12 hours, completely dissolved the product in the solvent, and obtained a solution containing the crude lithium bisoxalate borate.

[0066] Transfer the solution containing the crude lithium bisoxalate borate to a concentration kettle, and concentrate the solution to 80% of the original volume by heating, after cooling it to room temperature, add 150g of dichloromethane for crystallization, and filter to obtain the The wet product of the solvent, which was transferred to the lithium bisoxalate borate product of the organic solvent was dried in a 316L stainless steel drier to obtain the lithium bisoxalate borate product.

[0067] The quality of the obtained lithium bisoxalate borate product after drying was 48.72g, the purity of the obtained product was 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com