Silicon core quantum dot shell composite nano material, preparation method, application and product

A technology of composite nanomaterials and quantum dots, which is applied in the field of silicon core quantum dot shell composite nanomaterials and preparation, can solve the problems of limiting the application in the field of immunochromatography, difficult to recover by centrifugation, etc., and achieve superior performance, convenient storage, and dispersibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

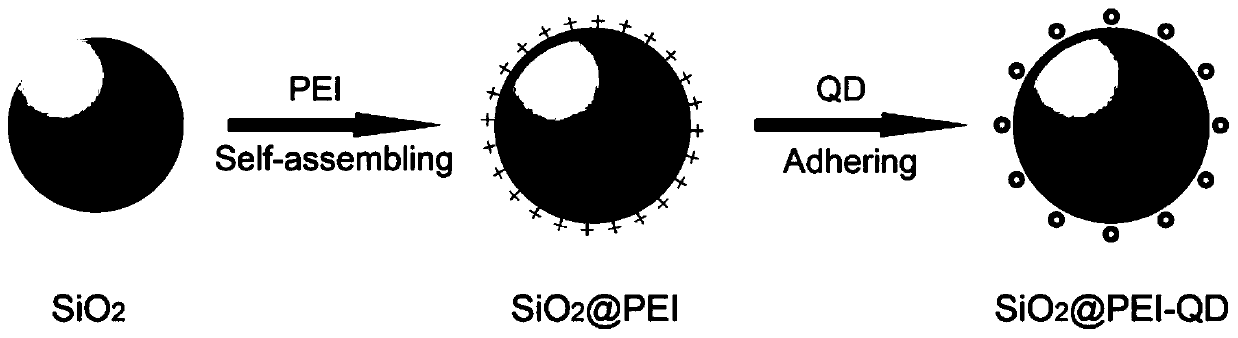

[0076] The present invention also includes the preparation method of the above-mentioned composite nanomaterial, comprising the following steps: 2 The electropositive polymer is modified on the surface of the nanoparticle, and then the carboxylated quantum dot is modified to obtain a composite nanomaterial.

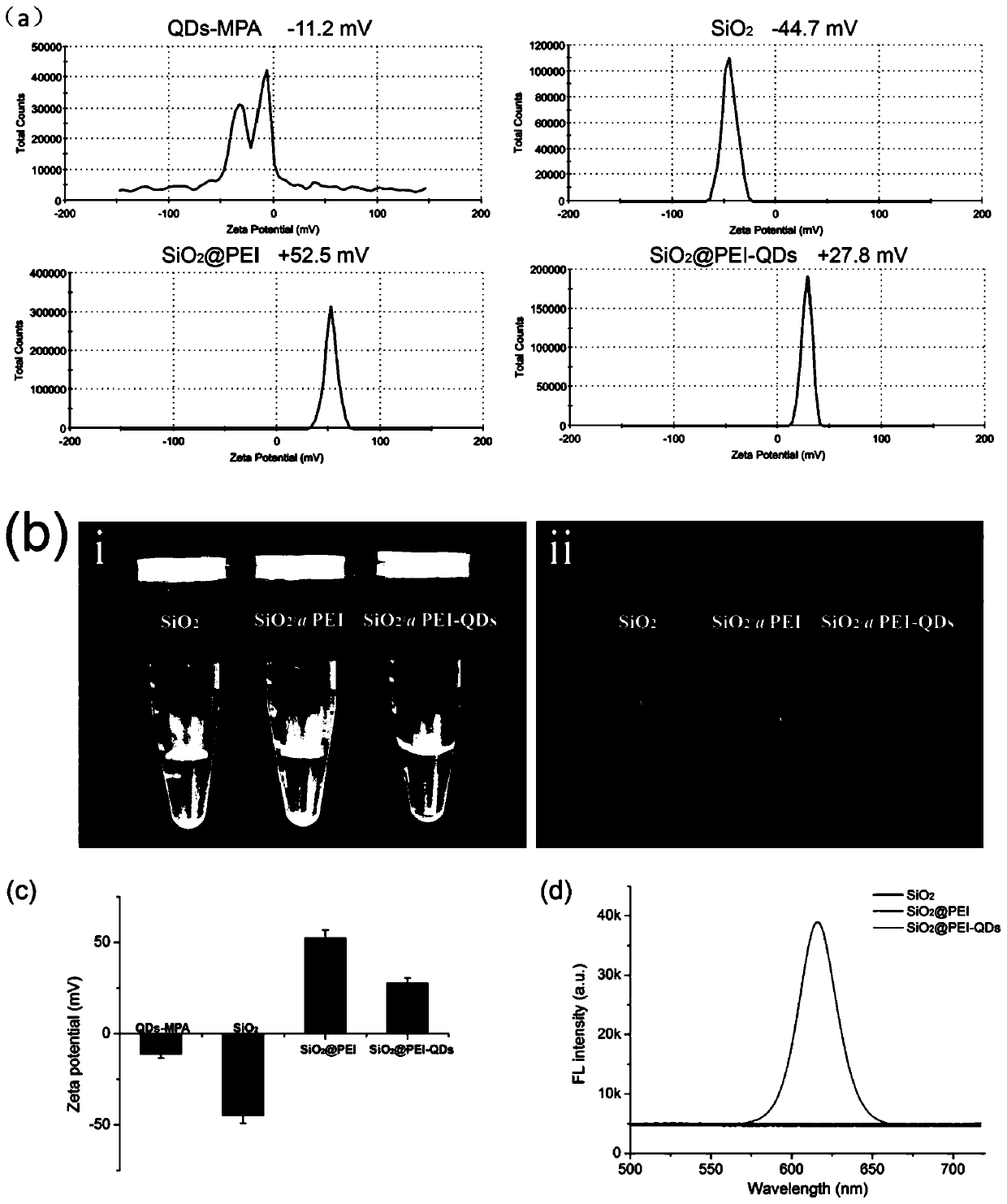

[0077] Specifically, SiO 2 The nanoparticles are negatively charged, and the positively charged polymers with positive charge act on SiO 2 Surface self-assembly of nanoparticles to form SiO surface-modified with electropositive polymers 2 Nanoparticles, and then use the charge to decorate the negatively charged quantum dots on the surface of the positively charged polymer to obtain a composite nanomaterial. The invention utilizes the self-assembly property of the electropositive polymer and adopts a layer-by-layer self-assembly method to prepare composite nanomaterials. The preparation method is simple, mature and repeatable, and can realize large-scale production.

[...

Embodiment 1

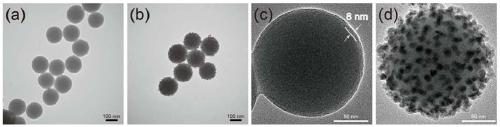

[0088] A silicon core quantum dot shell composite nanomaterial prepared by the present invention, including SiO 2 Quantum dot shell composed of core, PEI interlayer and carboxylated quantum dots modified with mercaptopropionic acid (MPA), SiO 2 The particle size of the particles is 150nm, the thickness of the PEI self-assembled layer is 5nm, the particle size of the adsorbed carboxylated quantum dots (CdSe / ZnS-COOH) is 10nm, and the final particle size of the silicon ball quantum dots is about 180nm, which has good dispersion and fluorescence properties.

[0089] A preparation method of the silicon core quantum dot shell composite nanomaterial of the above-mentioned present embodiment, such as figure 1 shown, including the following steps:

[0090] (1) Preparation of 150nm SiO with good dispersion 2 core:

[0091] Add 100mL of absolute ethanol, 6mL of deionized water, and 28% ammonia water into a 200mL jar in turn, add a clean stir bar, and stir magnetically for 20min. St...

Embodiment 2

[0099] The outermost layer of the silicon core quantum dot-shell composite nanomaterial in Example 1 is a carboxylated quantum dot structure modified by mercaptopropionic acid (MPA), and the surface has a large number of free carboxyl groups that can be used for antibody coupling, and can realize nano Surface functionalization of materials. The steps of antibody modification on the surface of the silicon core quantum dot shell composite nanomaterial of the present invention are as follows: Figure 5 shown, including the following steps:

[0100] 1mg SiO 2 @QDs powder was dissolved in 1 mL of 2-(N-morpholine)ethanesulfonic acid solution (0.1M, pH5.5), then 100 μL of carbodiimide solution (0.01M) and 20 μL of N-hydroxysuccinimide solution were added (0.1M), ultrasonic reaction for 15min to activate SiO 2 Carboxyl groups on the surface of @QDs; SiO was then recovered by centrifugation 2 @QDs, resuspend in 200 μL PBST solution (0.01M, pH7.4); add 15 μg antibody, shake at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com