Graphene/carbon/ferroferric oxide nano composite material as well as preparation method and application thereof

A technology of nanocomposite materials and ferroferric oxide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reducing the utilization rate of active materials, reducing the cycle stability of batteries, and the utilization of active materials. It can improve the overall lithium storage performance, improve the electrochemical performance, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of graphene / carbon / ferric oxide nano composite material comprises the steps:

[0030] Step 1: Weigh 6g of ferric nitrate nonahydrate, 2g of glucose and 30g of sodium chloride, dissolve them in 80mL of deionized water, then add 20mL of graphene oxide aqueous solution with a concentration of 2mg / mL, and disperse to obtain a uniform mixed solution. Then the mixed solution was continuously stirred on a heating platform at 80°C to obtain a thick solid until it was completely dry, and then ground into powder to form a composite material precursor;

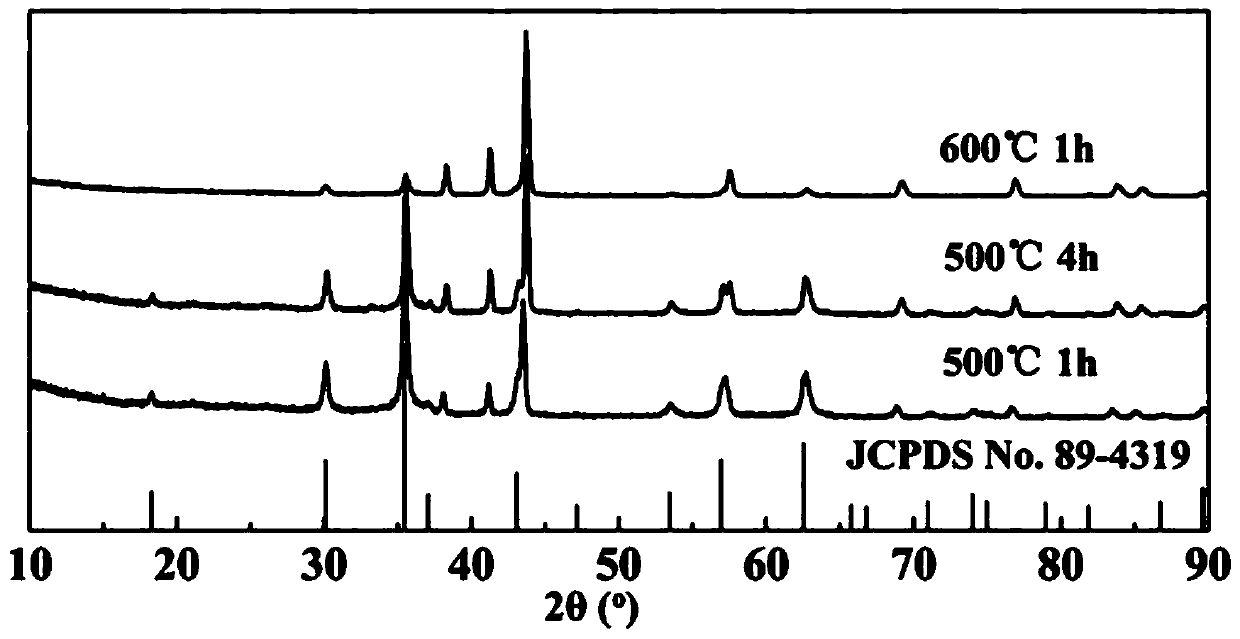

[0031] Step 2: Heat the powdered composite material precursor obtained in step 1 to 500°C at a rate of 5°C / min in argon, and then cool down to room temperature after constant temperature heat treatment for 4 hours. Graphene oxide is reduced to graphene and glucose by high temperature. After thermal decomposition, it is converted into a carbon material matrix, and iron nitrate is thermally decomposed to...

Embodiment 2

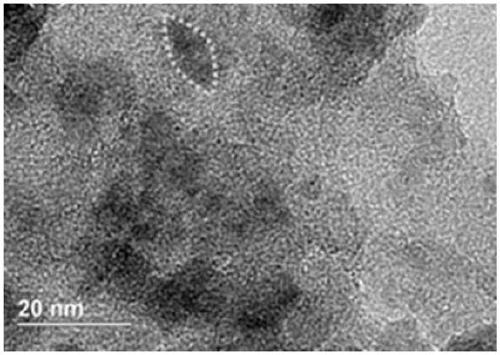

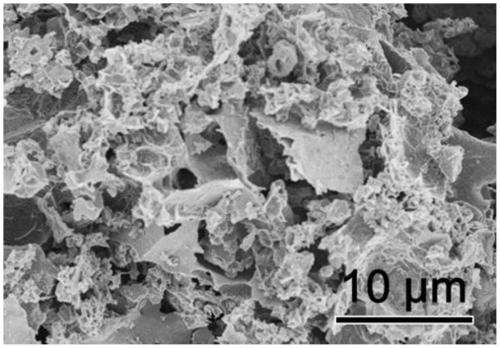

[0036] Such as figure 1 and 2 Shown, the graphene / carbon / ferric oxide nanocomposite material that embodiment 1 prepares, comprises the sheet structure framework, carbon material and iron ferric oxide nanoparticle with nanometer thickness and micron width that are formed by graphene, so The sheet-like structure skeleton is connected with the carbon material to form a graphene / carbon matrix with a porous network structure, and ferroferric oxide nanoparticles are evenly distributed and embedded in the porous network structure of the graphene / carbon matrix.

[0037] In this embodiment, the carbon material obtained by the cracking of carbon-containing compounds is used as a matrix to encapsulate and carry iron tetroxide nanoparticles, and to connect graphene and oxide nanoparticles as a whole; the full dissolution of soluble iron-containing chemicals is conducive to The formation of tiny, uniformly distributed Fe3O4 nanoparticles, embedded in the carbon matrix, and the introductio...

Embodiment 3

[0039] The difference between this example and Example 1 is that in Step 2 of this example, the heat treatment is at 500° C. for 1 hour, and other technical solutions are the same as in Example 1.

[0040] By performing the electrochemical performance test as in Example 1 on the graphene / carbon / iron tetroxide negative electrode material prepared in this example, the test result is: when the cycle performance test is carried out at a current of 1A / g, the first reversible capacity is 760mAh / g, the reversible capacity after 400 cycles is 850mAh / g; in the rate performance test, the reversible capacity at 0.2A / g current is 815mAh / g, and the reversible capacity at 10A / g current is 400mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com